The Foro 400 Drill is an electromechanical ice coring drill that retrieves 98 mm (3.86-inch) diameter x 1-meter-long ice cores to approximately 400 meters depth. Design of the Foro 400 Drill was initiated in PY 2015 based on driller feedback with the aging 4-Inch Drill, and to utilize more recent and proven designs from other IDP drill systems. The drill is expected to largely replace use of the 4-Inch Drill equipment; however at least one full 4-Inch sonde will be retained for use on science projects requiring the larger 104 mm diameter core. The Foro 400 Drill produces a 98 mm (3.9-inch) diameter core, the same as IDP’s Foro 1650 Drill (aka Intermediate Depth Drill) and Foro 3000 Drill. In addition, the Foro 400 sonde design is submersible and watertight. The design is largely based on the current 4-Inch Drill equipment but offers generous weight savings. Using a common sonde design across several drills spreads design costs over multiple projects, strengthens component availability, and promises to reduce future maintenance costs. During a lull in fieldwork caused by the pandemic, IDP conducted beneficial hands-on training for several IDP Engineers at the UW Physical Science Lab (PSL) test well. The system was deployed to Antarctica for its first field project during the 2019-2020 field season at Allan Hills, Antarctica. The system was used again on Tunu Glacier in Greenland in spring 2022 and again at Allan Hills during the 2022-2023 Antarctic field season.

Minor modifications have been made following each of the drill’s field deployments. Fishing tools were fabricated and drill recovery loops procured in 2021. Slam Stick mounts were also fabricated to allow for collection of vibration data during coring. In 2022, scoop cutter shoes and sonde stands were procured. In 2023, IDP is pursuing the specification and purchase of aluminum outer tubes to replace the fiberglass tubes, as it is believed the fiberglass is creating heat, chip transport issues and poor core quality at depth. A collet cutter head was also designed and fabricated.

|

|

||

|---|---|---|

| 4-Inch Drill | Foro 400 Drill | |

| Winch Capacity | Up to 400 m of 13 mm ø Kevlar Cable | Up to 470 m of 5.7 mm ø steel armor cable |

| Ice Core Diameter | 104 mm | 98 mm |

| Hole Diameter | 145 mm | 126 mm |

| Ice Core Length | 1 m | 1 m |

| Pressure Rated Sonde | No | Yes |

| Winch Speed | 0.5 m/s | 0.76 m/s |

| Power Requirements/Source | 220V, 5 kW generator | 220V, 5 kW generator |

|

|

||

|---|---|---|

| 4-Inch Drill | Foro 400 Drill | |

| Drill | 87 kg (192 lbs) | 64 kg (141 lbs) |

| Winch with Cable | 297 kg (655 lbs) | 123 kg (271 lbs) |

| Tower Assembly | 61 kg (135 lbs) | 52 kg (115 lbs) |

| Control System | 52 kg (115 lbs) | 35 kg (77 lbs) |

| Total System Weight | 497 kg (1096 lbs) | 274 kg (604 lbs) |

| Shipping Weight (complete system including crates, spares, and tools) | 1,180 kg (2600 lbs) | 816 kg (1800 lbs) |

Equipment Details

| Name | Foro 400 Drill |

|---|---|

| Type |

Type

Ice coring

|

| Number in Inventory |

Number in Inventory

1

|

| Max. Practical Depth |

Max. Practical Depth

400 m

|

| Ice Core Diameter |

Ice Core Diameter

98 mm (3.85 inches)

|

| Ice Core Length |

Ice Core Length

1 m

|

| IDP Driller Required? |

IDP Driller Required?

Yes

|

| Drill Fluid Required? |

Drill Fluid Required?

No

|

| Helicopter Transportable? |

Helicopter Transportable?

Yes

|

| Light Aircraft Transportable? |

Light Aircraft Transportable?

Yes

|

| Shipping Weight |

Shipping Weight

1800 lbs |

| Shipping Volume (Cube) |

Shipping Cube

200 m system can be broken down so individual pieces weigh less than 100 lbs and are under 6 ft3 |

| Comments |

Documents

| Citation | Year |

|---|---|

| U.S. Ice Drilling Program (2021) Foro 400 Drill Operations and Maintenance Manual. 1-42. | 2021 |

| Mary R Albert, Kristina R Slawny, Grant Boeckmann, Chris J Gibson, Jay A Johnson, Keith Makinson, Julius Rix (2020) Recent Innovations in Drilling in Ice. Chapter 6 of Advances in Terrestrial Drilling: Ground, Ice and Underwater, Bar-Cohen and Zacny, eds., 157-220. https://www.routledge.com/Advances-in-Terrestrial-Drilling-Ground-Ice-and-Under… | 2020 |

| Jay A Johnson, Matthew J Kippenhan (2017) DISC Drill vs. Foro 3000 Drill Analysis. 1-24. | 2017 |

| IDDO (2015) Foro Drill System Preliminary Engineering Design Review. 1-26. | 2015 |

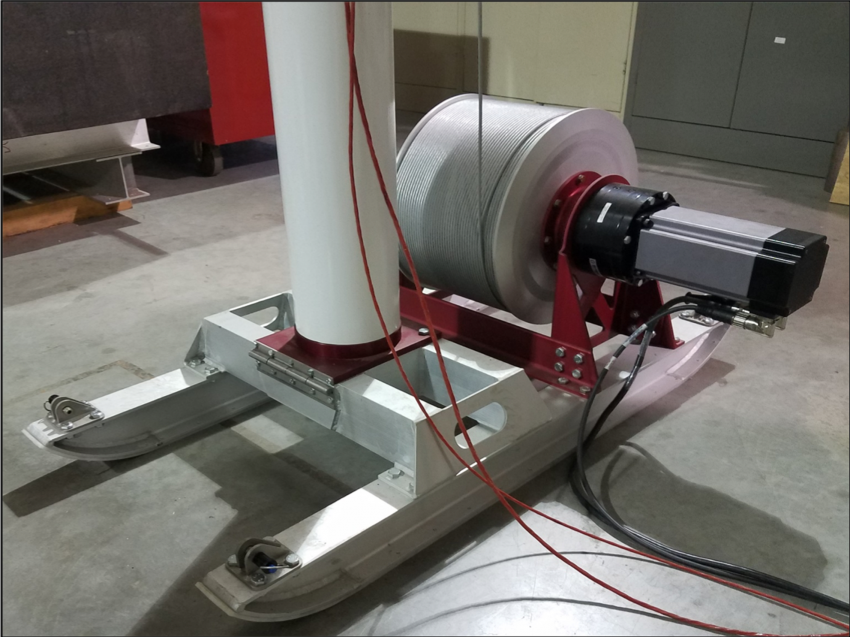

Photos

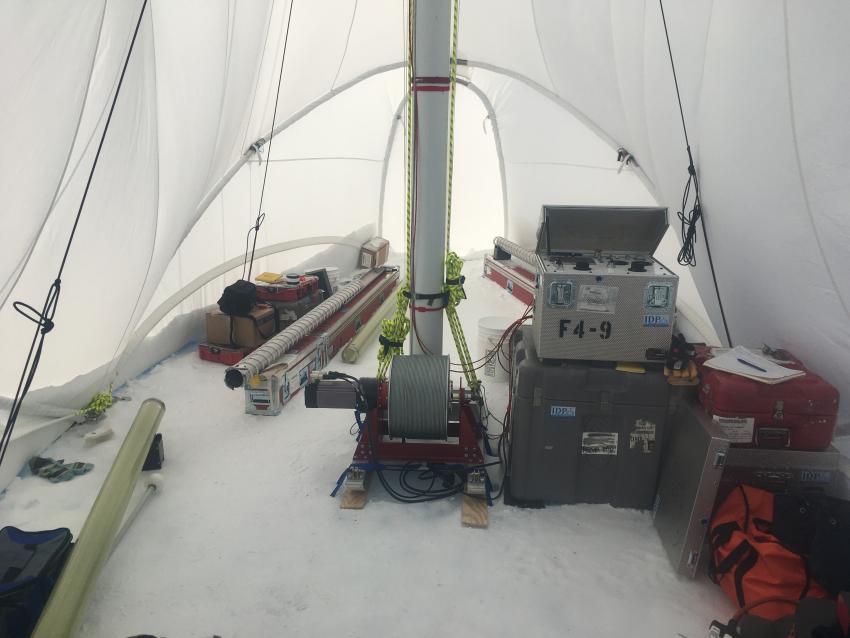

The drill tent for the Foro 400 drill in use for its first time at Allan Hills, Antarctica, during the 2019/20 field season. Credit: Elizabeth Morton

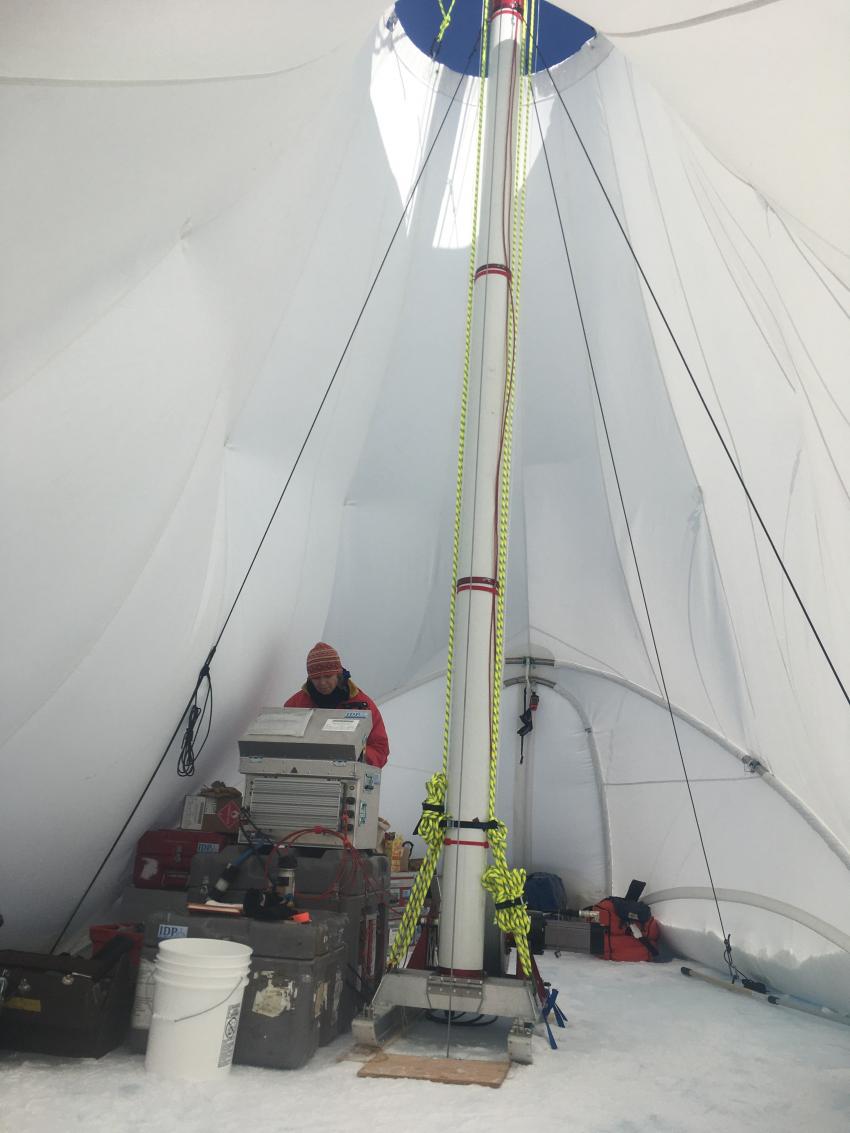

Driller Elizabeth Morton operates the Foro 400 Drill at Allan Hills, Antarctica, during the 2019/20 field season. Credit: Tanner Kuhl

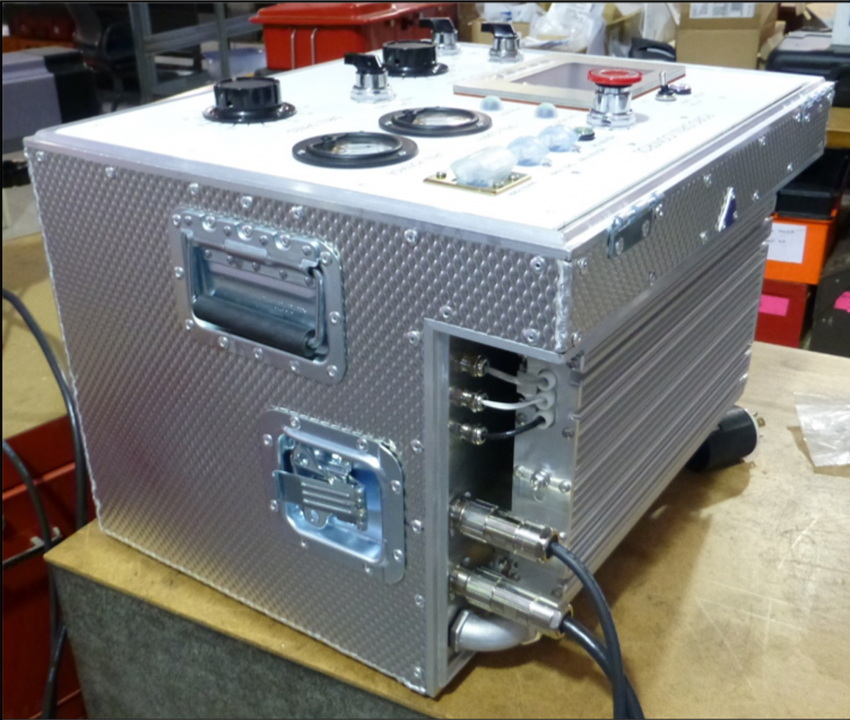

The Foro 400 Drill's control box designed for operation in cold and wet conditions. Controls are laid out for use while wearing gloves. The LCI-90i line control meter displays line tension, payout, speed, core length, and weight-on-bit. An internal siren and light on the faceplate alert the operator if the anti-torque is slipping downhole. Credit: Jay Johnson

The Foro 400 Drill's control box designed for operation in cold and wet conditions. Controls are laid out for use while wearing gloves. The LCI-90i line control meter displays line tension, payout, speed, core length, and weight-on-bit. An internal siren and light on the faceplate alert the operator if the anti-torque is slipping downhole. Credit: Jay Johnson

Shipping weight listed above includes all spares and shipping cases. For ultra-lightweight deployments, where spares and shipping cases can be left at a base camp, the weight of the winch, tower, one control box and one sonde is estimated at 604 lbs.