In 2015, community scientists identified the need for a lightweight coring drill, able to be transported by backpack. IDP researched commercially available systems and considered designing a new tool. In the end, a commercially available drilling system was purchased from Icedrill.ch in Switzerland in 2016.

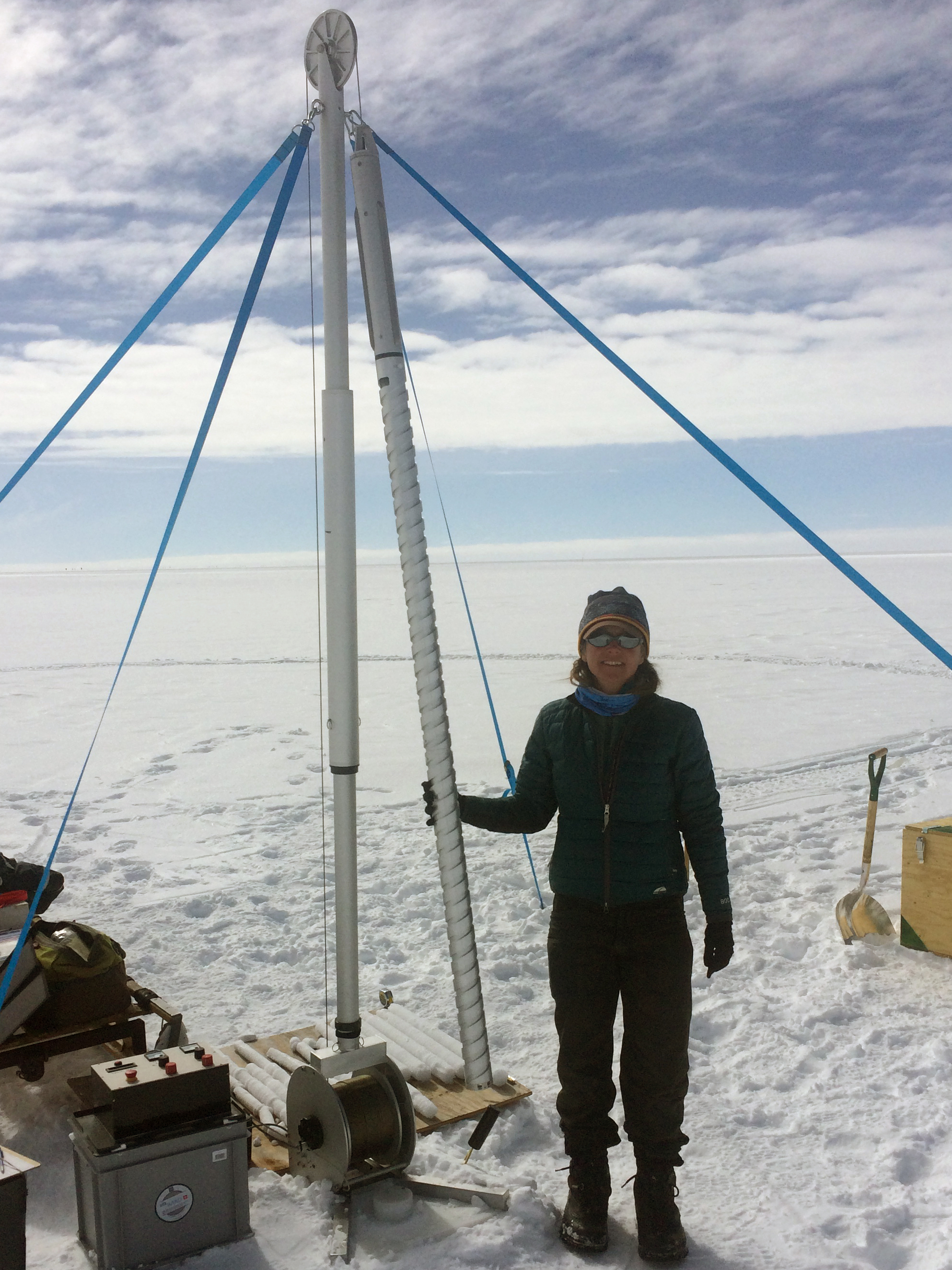

The Stampfli 2-Inch Drill is a lightweight electromechanical drill that takes a 57 mm (2-inch) diameter core. The drill system fits inside one helicopter or twin otter, and is packed in pieces that can be lifted by one person and transported up a mountain solely by a human on foot or skis. A lightweight Tentipi Safir tent for use with the system is also available.

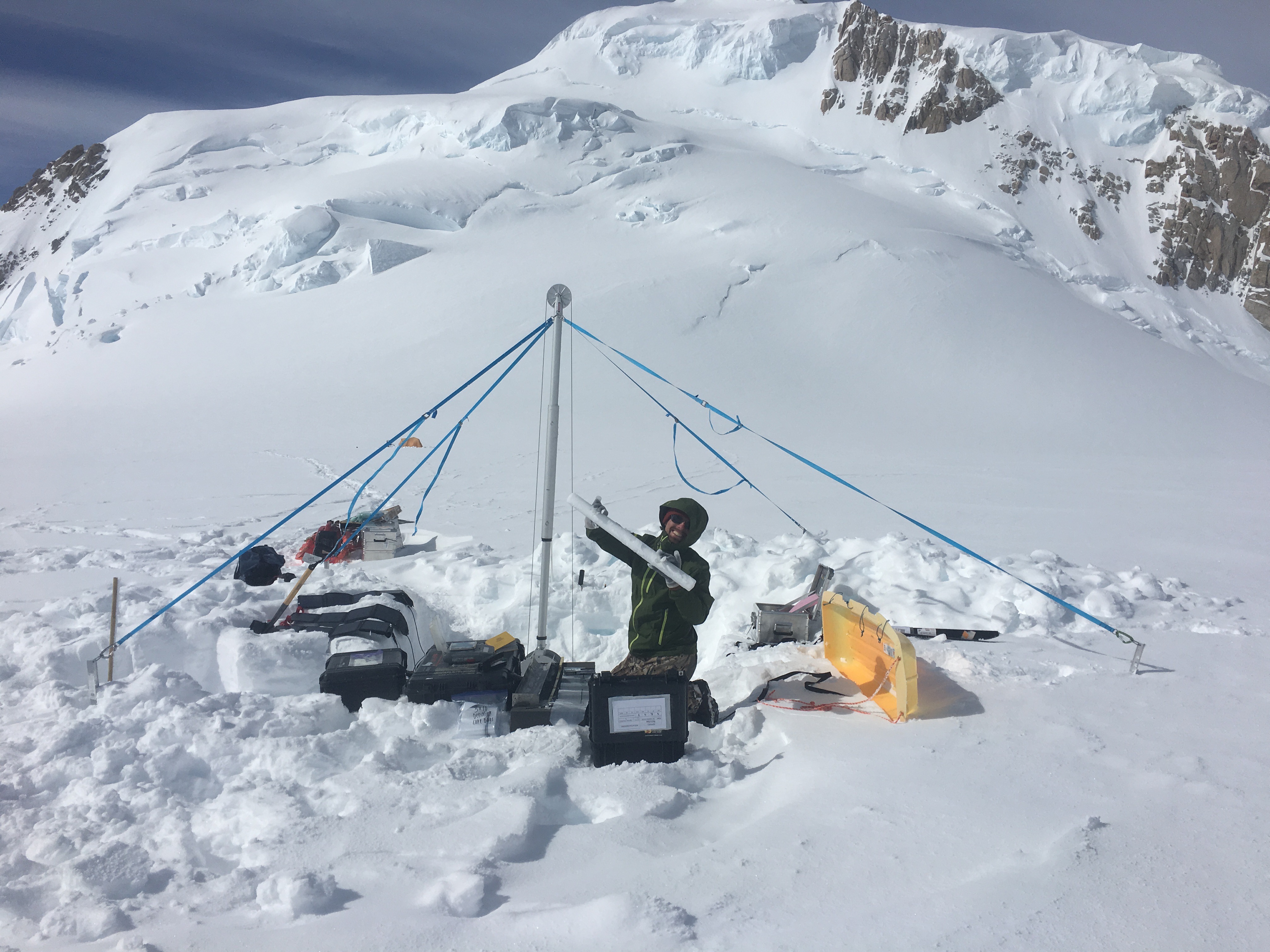

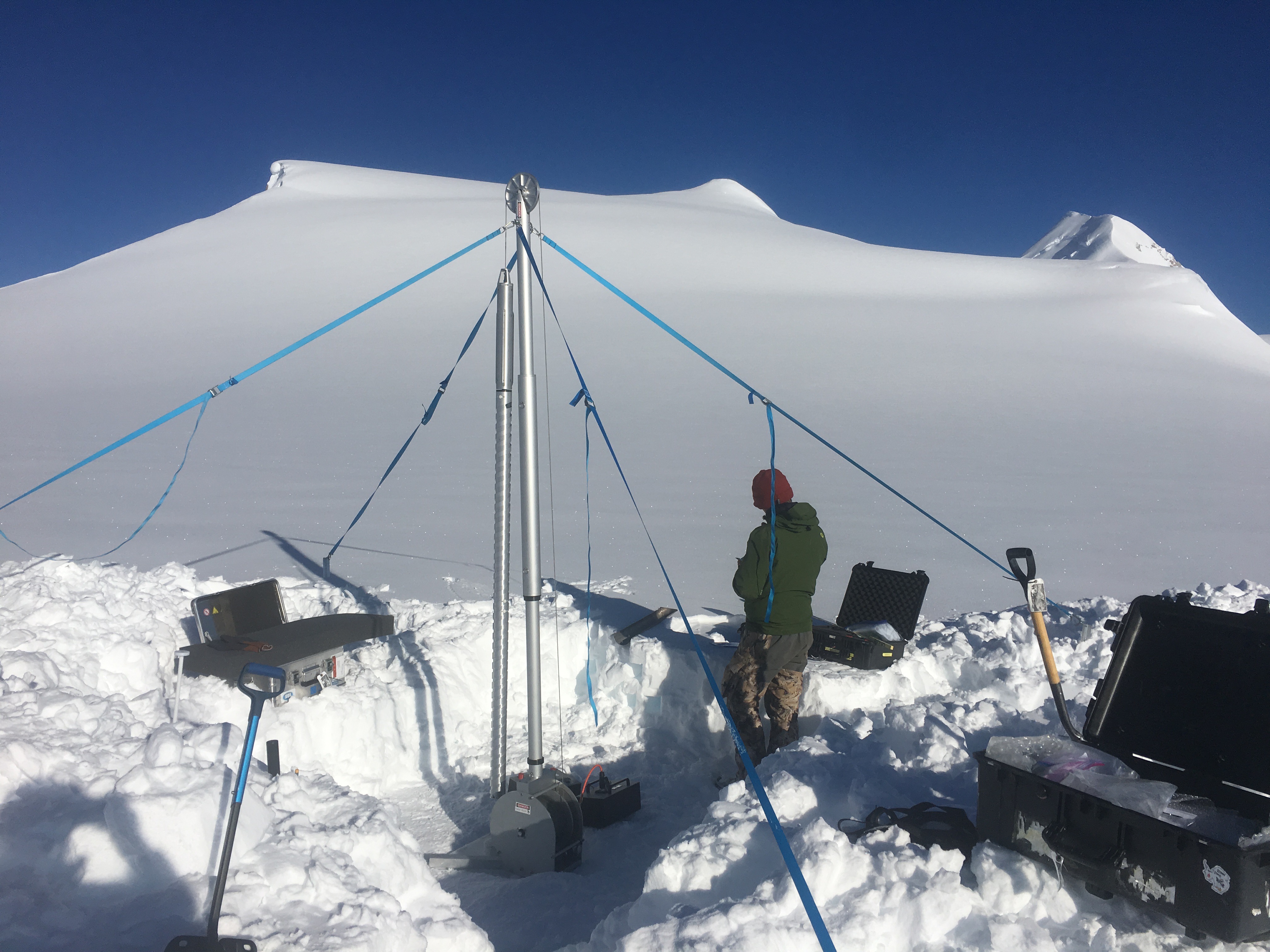

The system was deployed in 2018 in the Yukon Territory, Canada, where it was operated by the science team to collect one firn core to 10 m depth and another to 20 m depth. In 2019, a science team successfully collected a 50 m core from the summit plateau of Mt. Hunter in Denali National Park, Alaska.

The drill can be operated with either solar panels or a gas engine.

Equipment Details

| Name | Stampfli Drill |

|---|---|

| Type |

Type

Ice coring

|

| Number in Inventory |

Number in Inventory

1

|

| Max. Practical Depth |

Max. Practical Depth

50 meters, depending on conditions

|

| Hole Diameter |

Hole Diameter

72 mm (2.8 inches)

|

| Ice Core Diameter |

Ice Core Diameter

57 mm (2.2 inches)

|

| Ice Core Length |

Ice Core Length

0.8 m

|

| IDP Driller Required? |

IDP Driller Required?

Yes

|

| Drill Fluid Required? |

Drill Fluid Required?

No

|

| Power Requirements/Source |

Power Requirements/Source

Solar panels or 2 kW generator

|

| Estimated Drilling Time |

Estimated Drilling Time

20 m - 3 hr |

| Time to Move (breakdown and setup) |

Time to Move (breakdown and setup)

1 hour

|

| Helicopter Transportable? |

Helicopter Transportable?

Yes

|

| Light Aircraft Transportable? |

Light Aircraft Transportable?

Yes

|

| Shipping Weight |

Shipping Weight

380 lbs (including tent, excluding generator) |

| Shipping Volume (Cube) |

Shipping Cube

Appx 37 |

| Comments |

Documents

| Citation | Year |

|---|---|

| NSF Ice Drilling Program (2023) Stampfli Drill Operations and Maintenance Manual. 1-22. | 2023 |

| Erich Osterberg, Karl Kreutz, Sarah Das (2016) Science Requirements: Stampfli 2-Inch Drill. | 2016 |

Photos

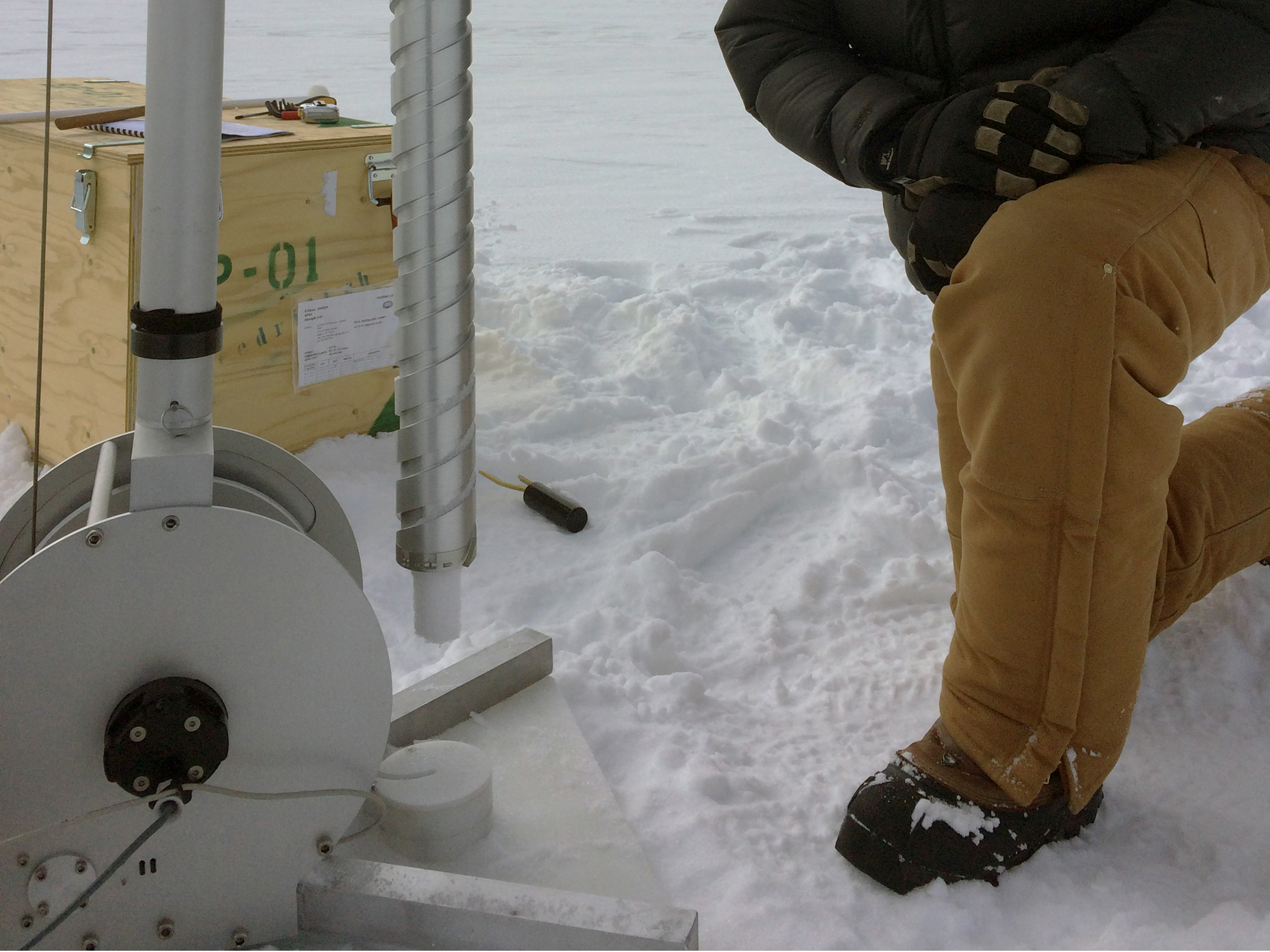

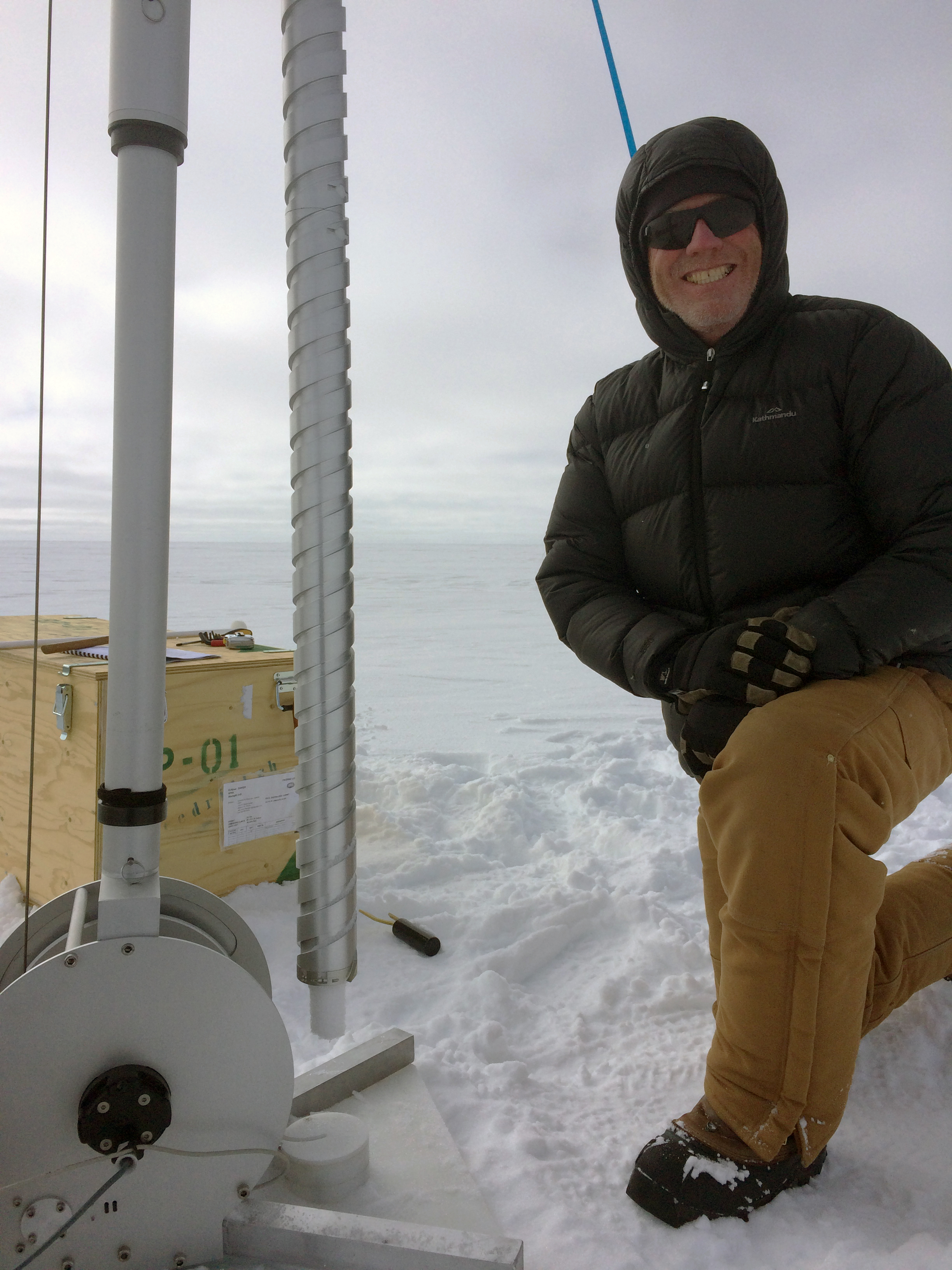

Researchers use the Stampfli Drill to collect a 50-meter long core from the summit plateau of Mount Hunter, Alaska. Credit: David Polashenski

Researchers use the Stampfli Drill to collect a 50-meter long core from the summit plateau of Mount Hunter, Alaska. Credit: David Polashenski

Operable in ambient temperatures down to -25°C. A back-packable tent for housing drilling operations is also included.