Born in Rock Springs, Wyoming, Don attended the University of Wyoming, completing a bachelor's degree in mechanical engineering in 1971. Don then worked for Questar Corporation, a natural gas energy company based in Salt Lake City, Utah, and enjoyed the challenges of integrating engineering practices and quality concepts. It was also at Questar where he met his wife, Nancy.

With an interest in engineering management, Don began pursuing an MBA at Westminster College in Salt Lake City and, subsequently, at the age of 50, left Questar to pursue his graduate degree full time. Despite being accepted into several MBA programs, the University of Wisconsin-Madison was a natural choice, particularly since his wife's family was located in and around Wisconsin. Apart from school and work, Don has been a member of the American Society of Mechanical Engineers (ASME) for the past 40 years, as well as a member of the American Society for Quality (ASQ) for the past 20 years.

In 1999, Don began the Master of Business program at UW- Madison, graduating in 2001 with a master of business degree in Manufacturing and Technology Management (MTM). After graduation, Don intended to do consulting work, but received a phone call in July 2001 from Bob Paulos, a project manager at the Space Science and Engineering Center (SSEC) on the UW campus, which would take his career in a new and exciting direction.

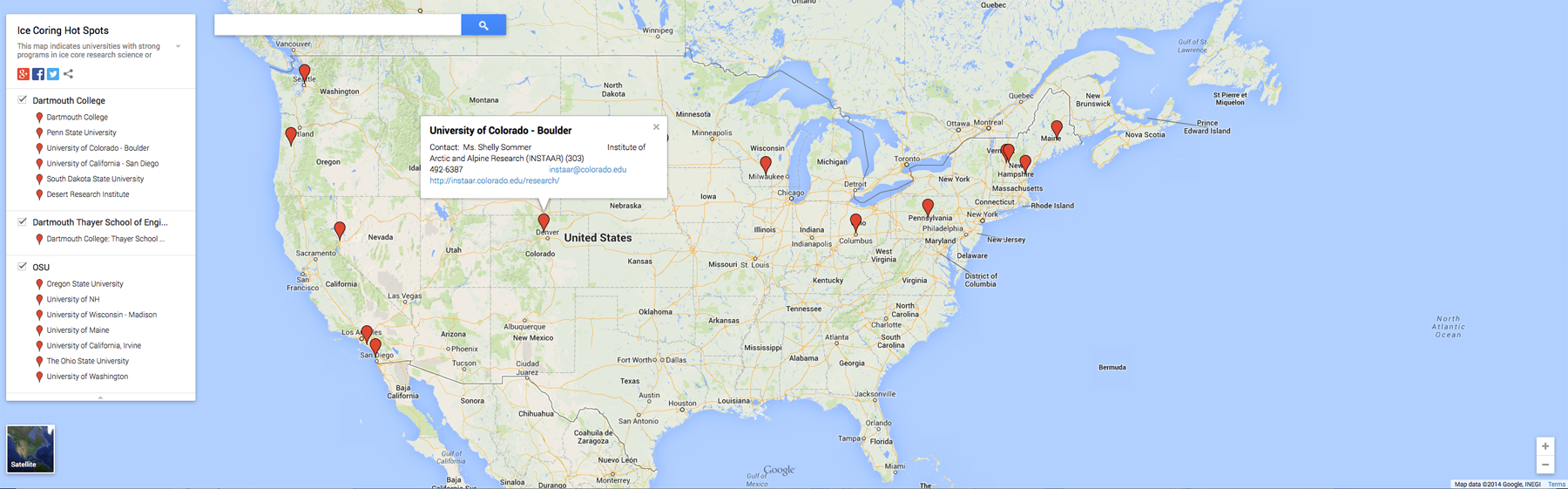

A fellow student in the MTM program, who was working at SSEC, had recommended Don for a position in his building. Don interviewed with both Bob and Charlie Bentley, the latter of whom was the principal investigator (PI) of Ice Coring and Drilling Services (ICDS), an engineering group within SSEC working under a grant from the National Science Foundation (NSF) to maintain the foundation's fleet of polar ice coring equipment as well as support science projects worldwide.

Don commented on how the job was the perfect fit, as it allowed him to blend three of his passions – engineering, management and science – into one position. In August 2001, Don was hired as the program manager of ICDS.

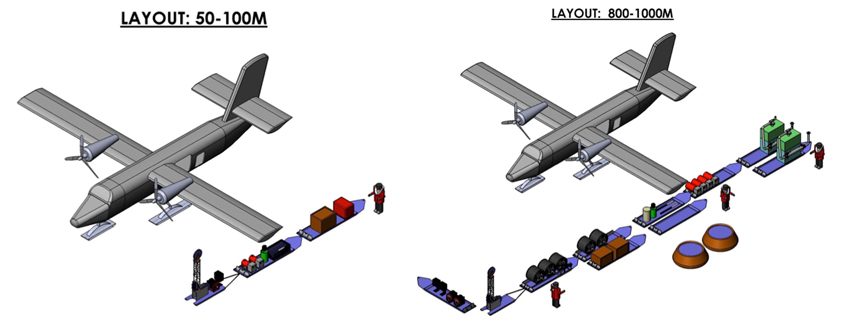

Years later, in 2008, ICDS became the Ice Drilling Design and Operations Group (IDDO), and began to operate under a cooperative agreement with the NSF and collaborate closely with a new organization, the Ice Drilling Program Office (IDPO) based at Dartmouth College and the University of New Hampshire. IDDO's goal was to carry on with the drill development, maintenance and upgrade tasks, and the field deployment of equipment and personnel that it had been doing for years. IDPO, in turn, would work with the science community to help determine equipment needs for the next decade and beyond.

In talking with Don about the things he has enjoyed most about his time at SSEC/ICDS/IDDO, Don said it is really the people within the organization that make it most satisfying – that, and the appeal of supporting critical science through a great array of polar projects over the years, have been very fulfilling, he said.

Having supported nearly 60 field projects since 2001, I asked Don if he had any favorite projects. Don discussed one particular project, the West Antarctic Ice Sheet (WAIS) Divide Deep Ice Core project, saying it was one of the most rewarding.

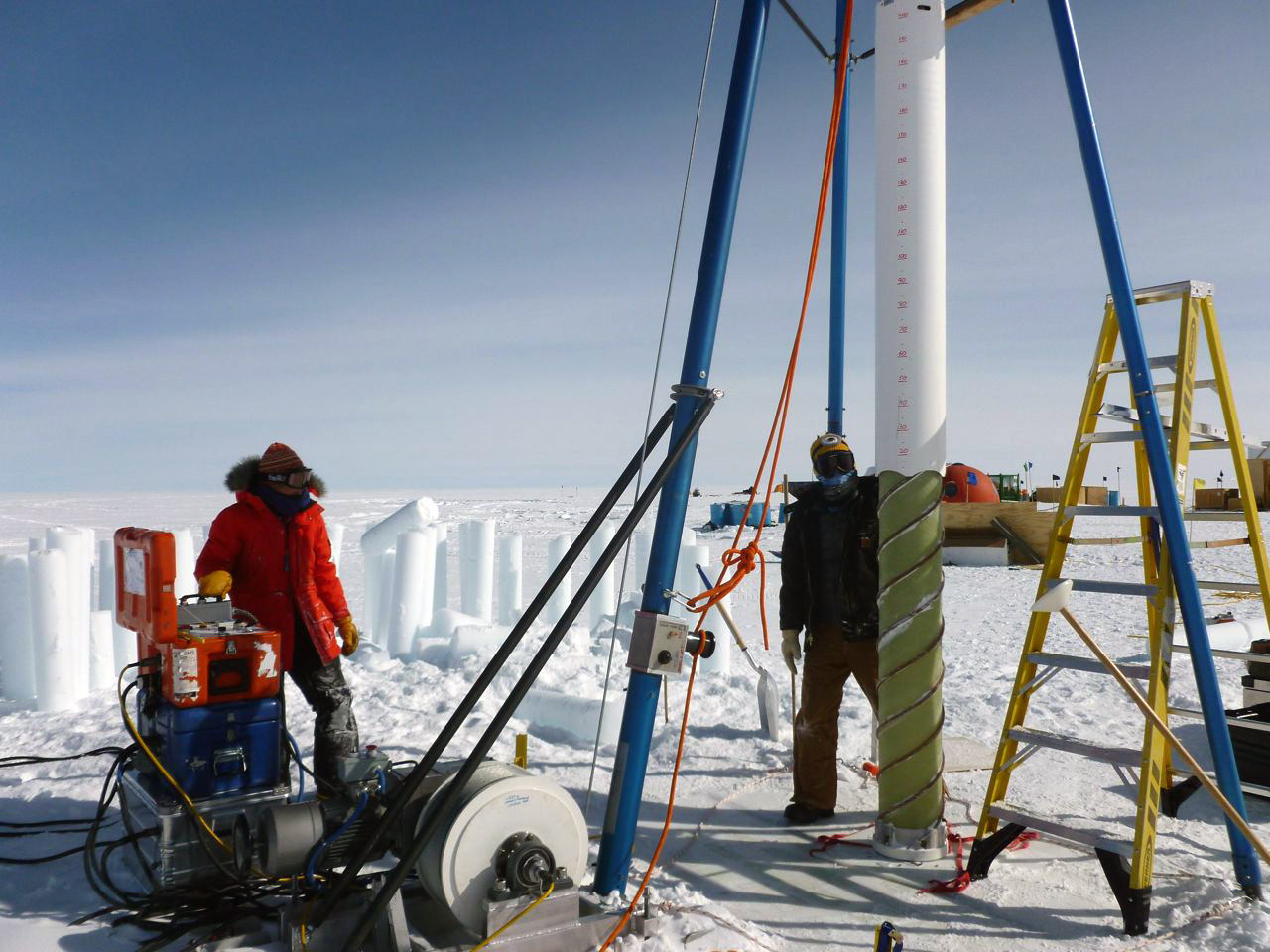

To date, the WAIS Divide Deep Ice Core project is the largest and longest project in the history of ICDS/IDDO. To complete the project, ICDS/IDDO designed and built the Deep Ice Sheet Coring (DISC) Drill, which operated at WAIS Divide in West Antarctica from 2007-2013. The WAIS Divide Ice Core is the deepest U.S. ice core collected to date.

Don recalled several things that drove the project's success, including close collaboration with WAIS Divide Chief Scientist Kendrick Taylor. This idea of collaboration between science and engineering set the tone for the project, with input from key players throughout its execution. ICDS/IDDO was also able to hone its driller-screening process during the multiyear project, gathering a premier group of hardworking and talented drillers from across the U.S. and the world. Don has always been a true believer in the effects of crew morale on performance in the field, noting that good relationships and morale lead to safe and successful working environments.