Per the Long Range Science Plan, a mid-range drill (700 m) is desired for use in remote areas such as mountain glaciers in the Arctic. Science Requirements were completed in March 2018 for a drill originally referred to as the Foro 700 Drill, as the idea was to utilize the current sonde design of the Foro 400, Foro 1650 and the Foro 3000 drills. IDP subsequently completed a Conceptual Overview of the system, and a conceptual design review was held in August 2019 with members of the science community. Following the review and in response to reviewer questions, IDP completed an analysis of the quantity of drill fluid and ice core boxes needed. Following further consultation with the science community on reducing the logistical burden of a new design, the IDP Science Requirements were updated based on an even smaller-diameter core than the Foro Drills or the Eclipse Drills. IDP subsequently updated the Conceptual Overview for the drill, now referred to as the 700 Drill, and held another review with science community representatives in January 2021. Following positive feedback from that review, IDP sought and gained NSF approval in March 2021 to move forward with the Detailed Design of the 700 Drill. The Detailed Design was completed and reviewed in November 2021, and NSF approval to move forward with fabrication of the drill was granted in February 2022. The final IDP Science Requirements for the 700 Drill, finalized in January 2021, identify a core diameter of 70 mm, with the drill to be designed in a way that a possible future core barrel with 64 mm diameter would be a minor adaptation.

Fabrication and assembly of the drill system is complete. The drill was shipped in May 2024 for first use on a funded science project at Summit Station in June and July.

Equipment Details

| Name | 700 Drill |

|---|---|

| Type |

Type

Ice coring

|

| Number in Inventory |

Number in Inventory

1

|

| Max. Practical Depth |

Max. Practical Depth

700 m

|

| Hole Diameter |

Hole Diameter

98 mm (3.86 inch)

|

| Ice Core Diameter |

Ice Core Diameter

70 mm (2.76 inch) initially, with potential future adaptation for 64 mm (2.52 inch) core

|

| Ice Core Length |

Ice Core Length

1 m

|

| Rock Core Diameter |

Rock Core Diameter

[NA]

|

| IDP Driller Required? |

IDP Driller Required?

Yes

|

| Drill Fluid Required? |

Drill Fluid Required?

Yes

|

| Helicopter Transportable? |

Helicopter Transportable?

Yes

|

| Light Aircraft Transportable? |

Light Aircraft Transportable?

Yes

|

| Shipping Weight |

Shipping Weight

6,300 lbs |

| Shipping Volume (Cube) |

Shipping Cube

420 cube |

| Comments |

Documents

| Citation | Year |

|---|---|

| NSF Ice Drilling Program (2021) 700 Drill Detailed Design Review - November 18, 2021. 1-58. | 2021 |

| Erich Osterberg, Karl Kreutz, Andrei Kurbatov, Mary R Albert (2021) Science Requirements: 700 Drill. 1-4. | 2021 |

| NSF Ice Drilling Program (2020) 700 Drill Conceptual Design Review - November 23, 2020. 1-24. | 2020 |

| Jay A Johnson, Matthew J Kippenhan (2017) DISC Drill vs. Foro 3000 Drill Analysis. 1-24. | 2017 |

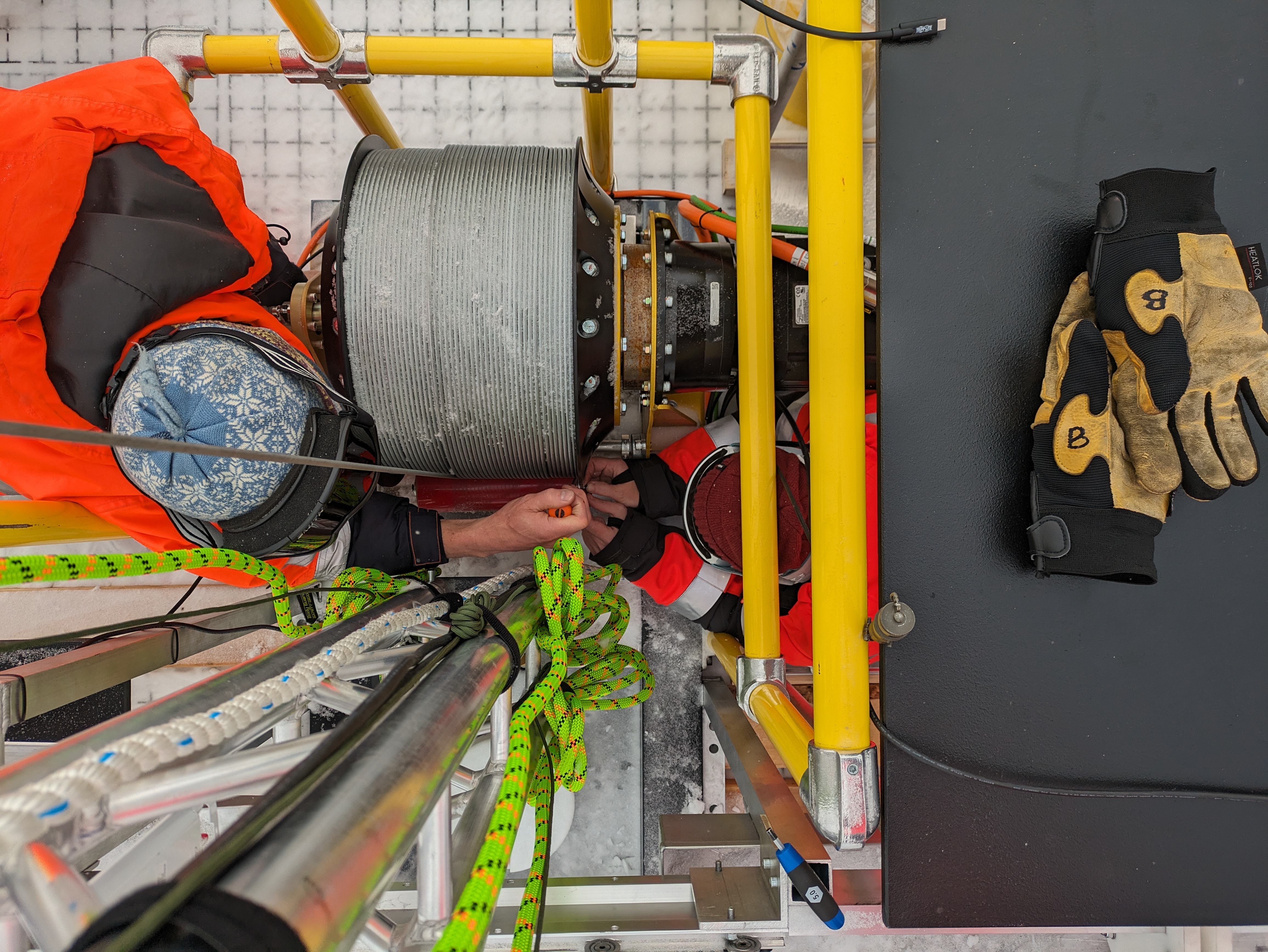

Photos

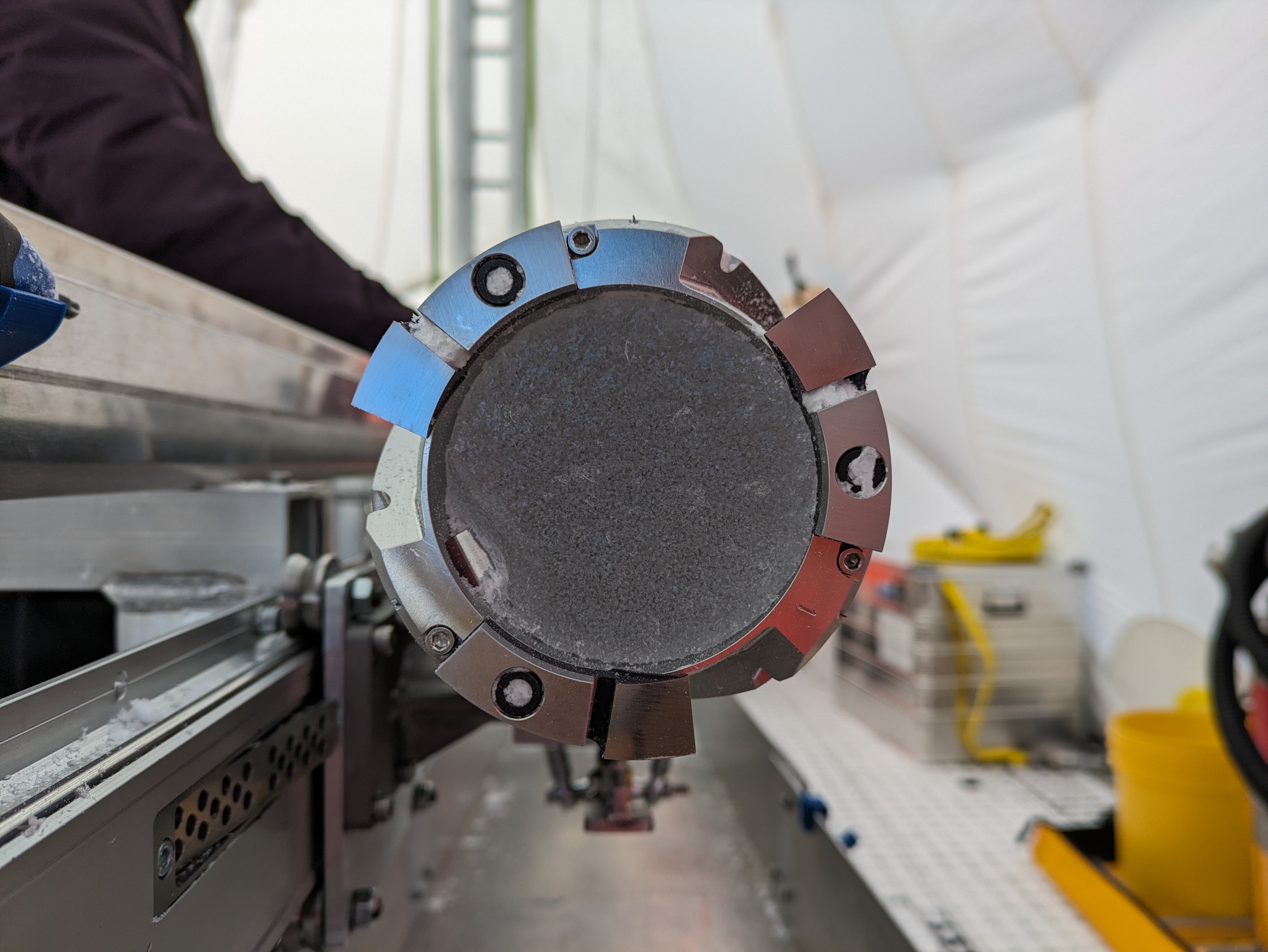

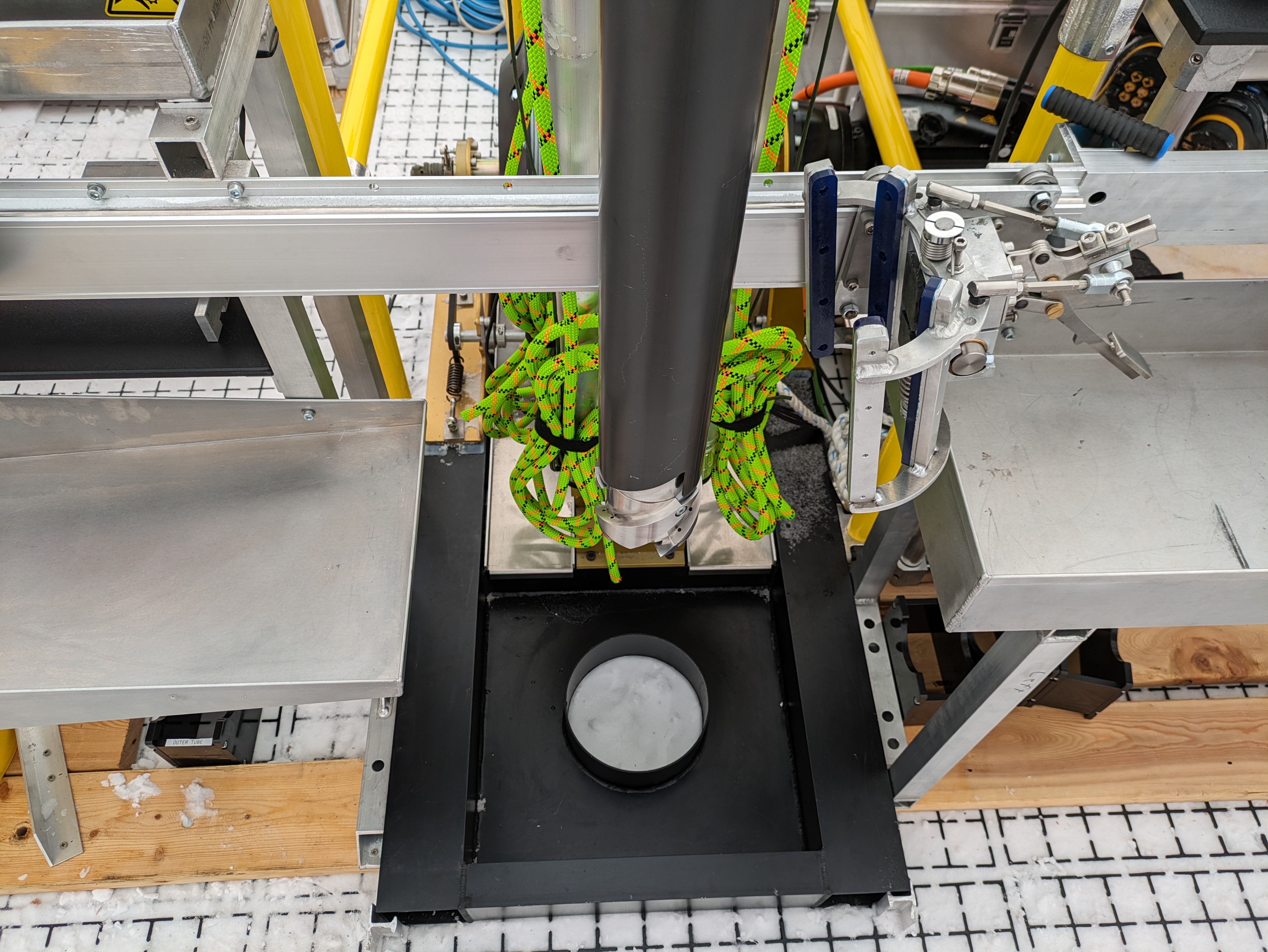

The cutter head of the 700 Drill at Summit, Greenland, during the 2024 field season. Credit: Umberto Stefanini.

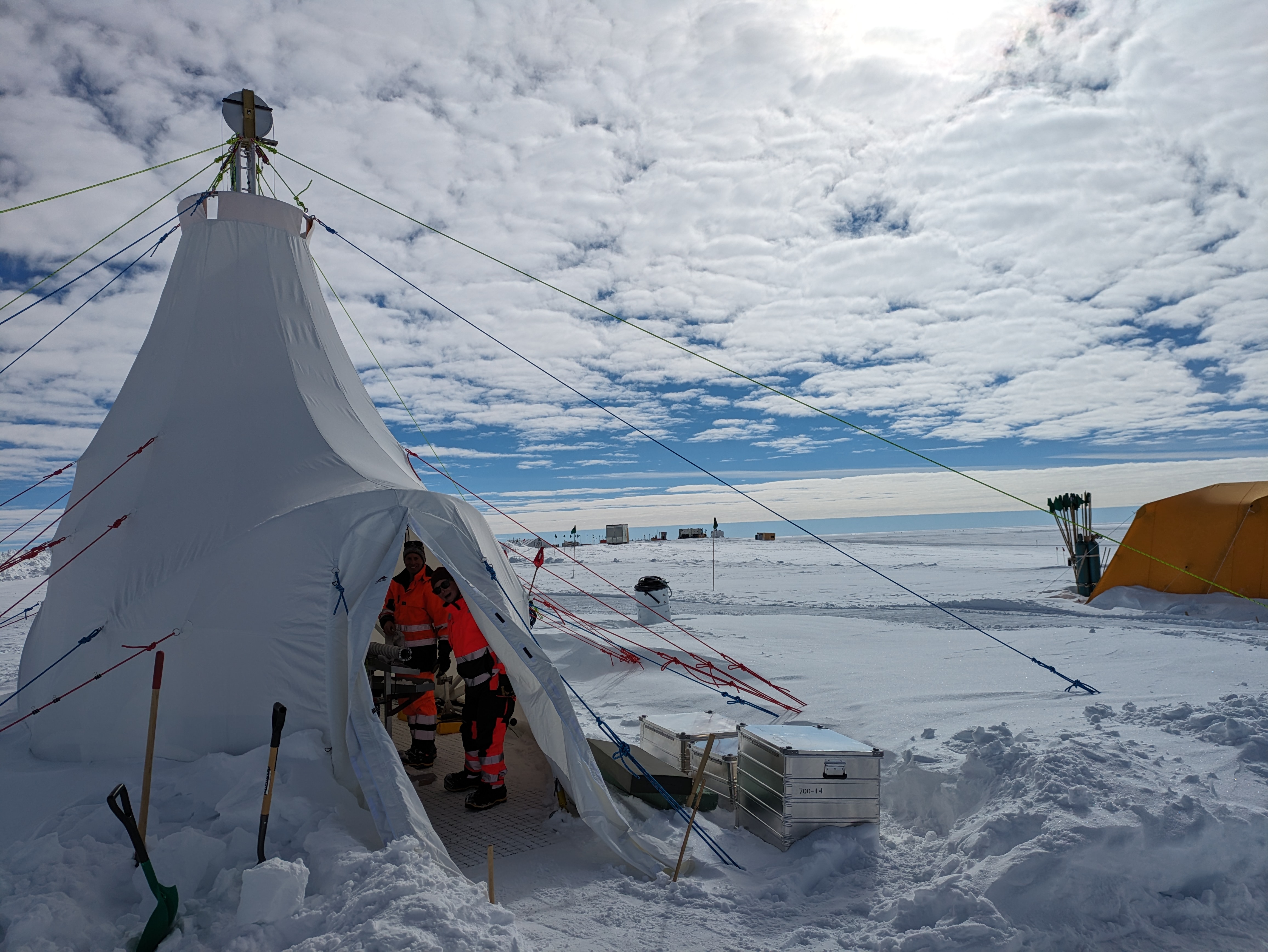

The drill tent for the 700 Drill at Summit, Greenland, during the 2024 field season. Credit: Umberto Stefanini.

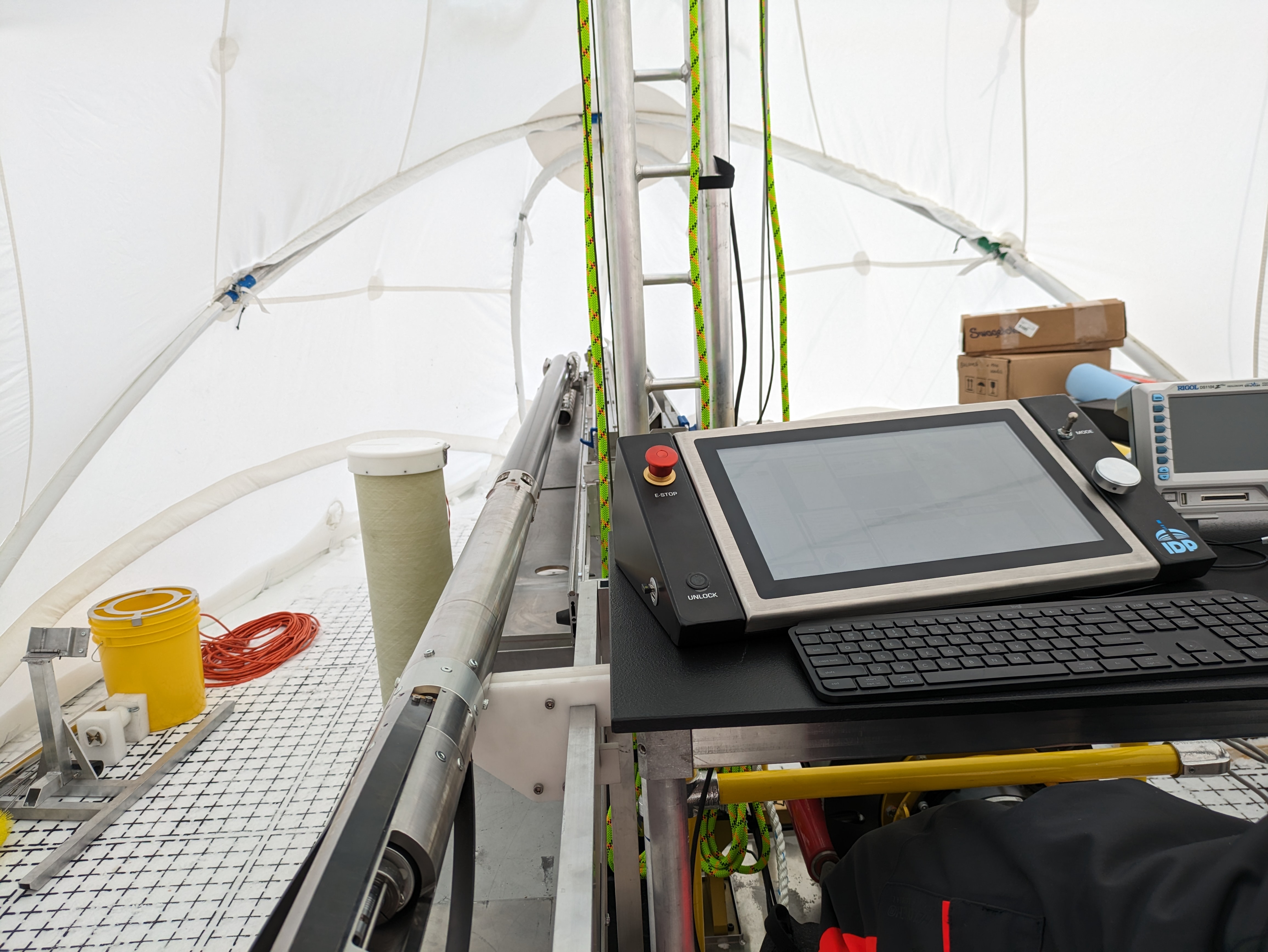

The drill tent for the 700 Drill at Summit, Greenland, during the 2024 field season. Credit: Umberto Stefanini

Shipping weight and cube listed above includes all spares, tools, two generators and shipping cases.