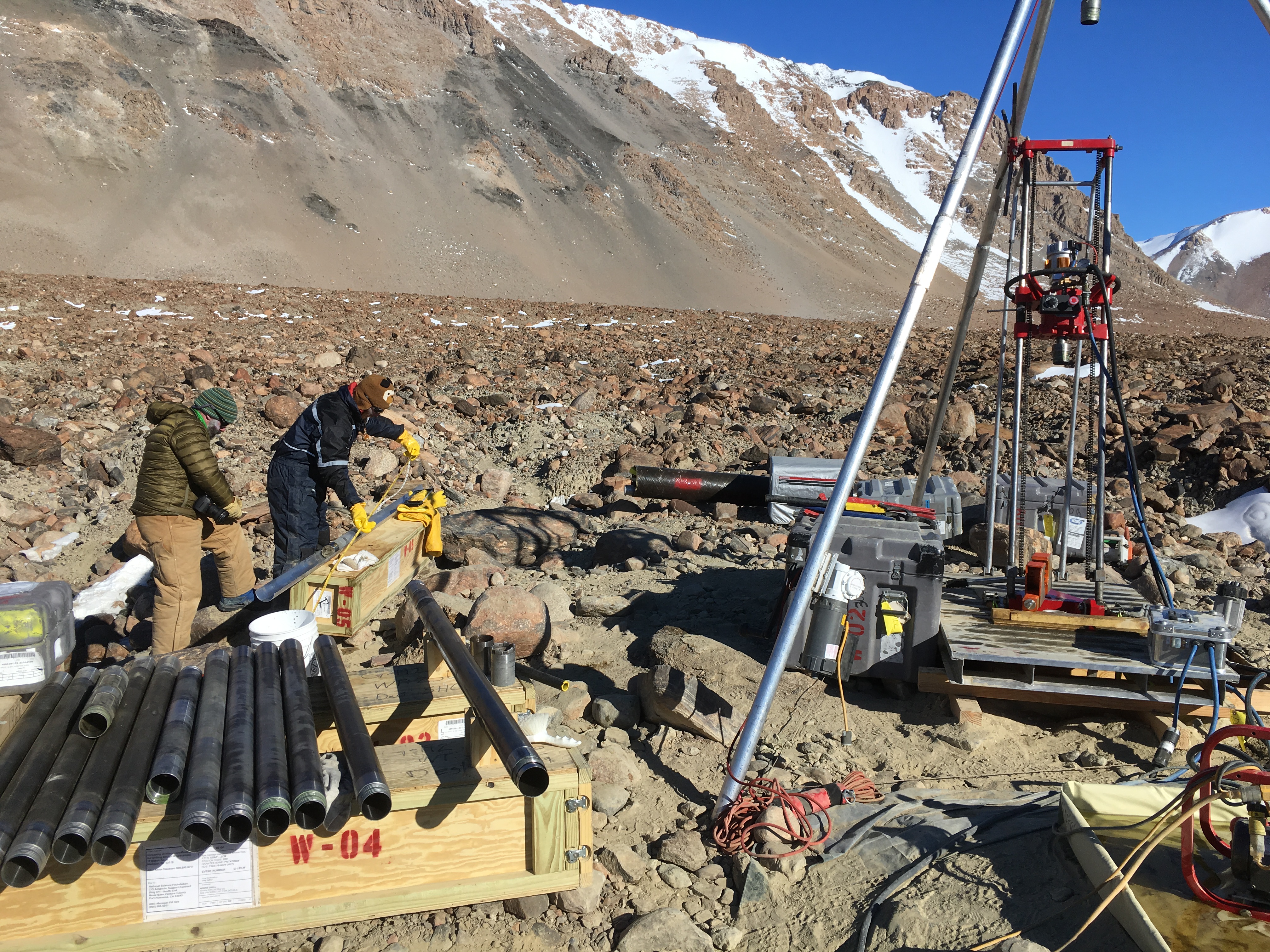

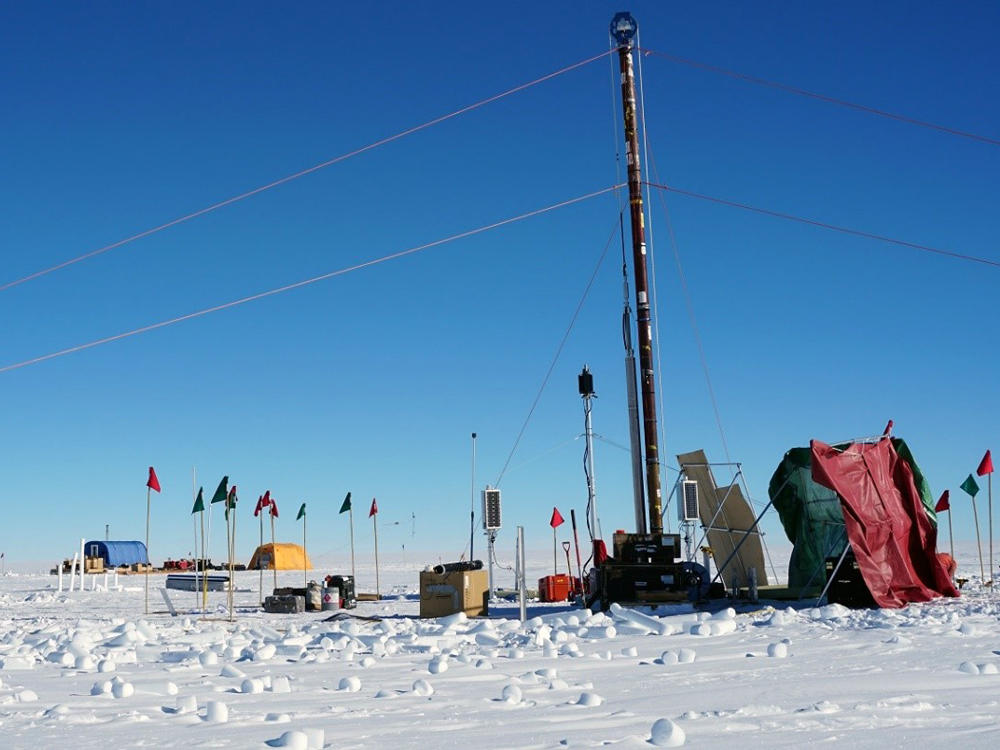

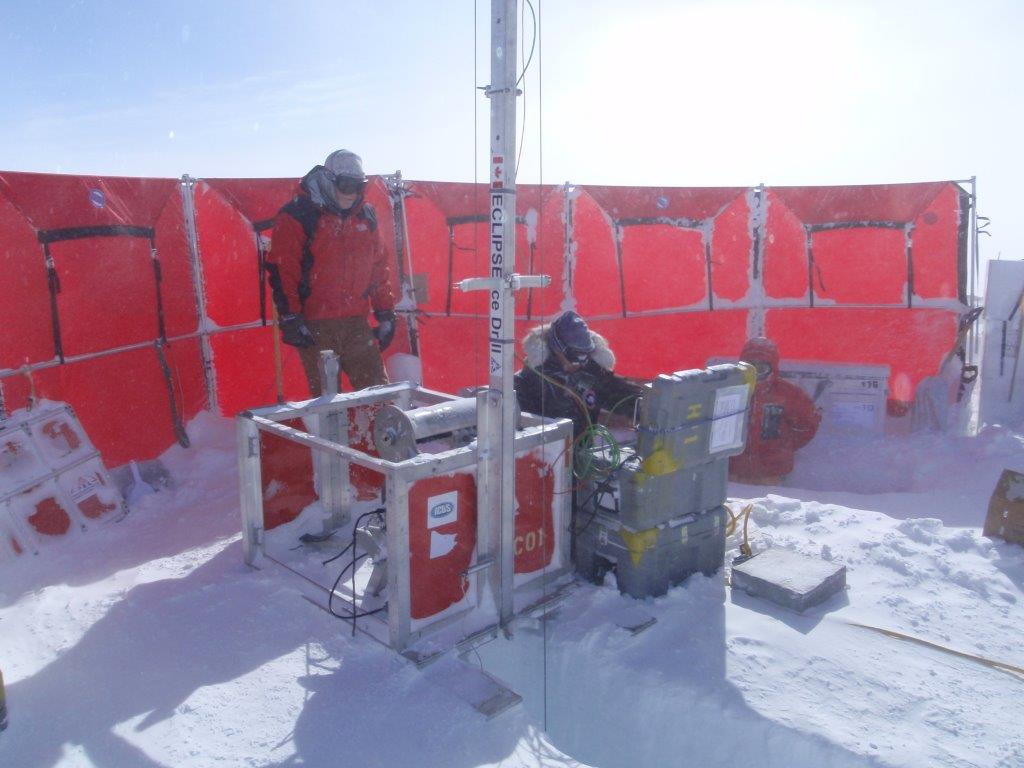

The 2019/20 Antarctic field season was a bustling time for IDP. The entire engineering staff of IDP deployed across five different sites. Using the Winkie Drill and Badger-Eclipse Drill, Engineer Grant Boeckmann and Research Intern Elliot Moravec successfully collected four subglacial rock cores on Thwaites Glacier in the Hudson Mountains for PI Brent Goehring’s project. Engineer Tanner Kuhl and Driller Elizabeth Morton supported PI John Higgins’s work at Allan Hills through operation of the Blue Ice Drill and the new Foro 400 Drill. IDP Warehouse Manager Jim Koehler operated the Intermediate Depth Logging Winch (IDLW) at South Pole Station in support of PI Kael Hanson’s logging of the SPICEcore borehole and then transitioned to WAIS Divide to assist Engineer Chris Gibson with testing of the new RAM 2 Drill components with the original RAM Drill compressors. They were also able to perform brief testing on the Small Hot Water Drill, which will serve as the backup drill for PI Sridhar Anandakrishnan’s GHOST project on Thwaites Glacier in 2020/21. Engineer Jay Johnson deployed to Minna Bluff with the RAID project at the request of PI John Goodge and the NSF. In addition to consulting on operation of the RAID equipment, Johnson also used an IDP 4-Inch Drill and chips bailer to assist in setting the RAID packer. He also re-terminated the IDLW cable following damage at South Pole and was assisted in this effort by Kuhl and Morton. The IDLW was then operated in two RAID boreholes by RAID and IceCube personnel. Despite substantial weather and aircraft delays program-wide, objectives were largely completed for all projects, and feedback received from PIs has been very positive.

4-Inch Drill

IDP Supports a Successful 2019/20 Antarctic Field Season

Field Support to Antarctic 2019-2020 Projects

IDP is providing support to the following projects during the 2019-2020 Antarctic field season:

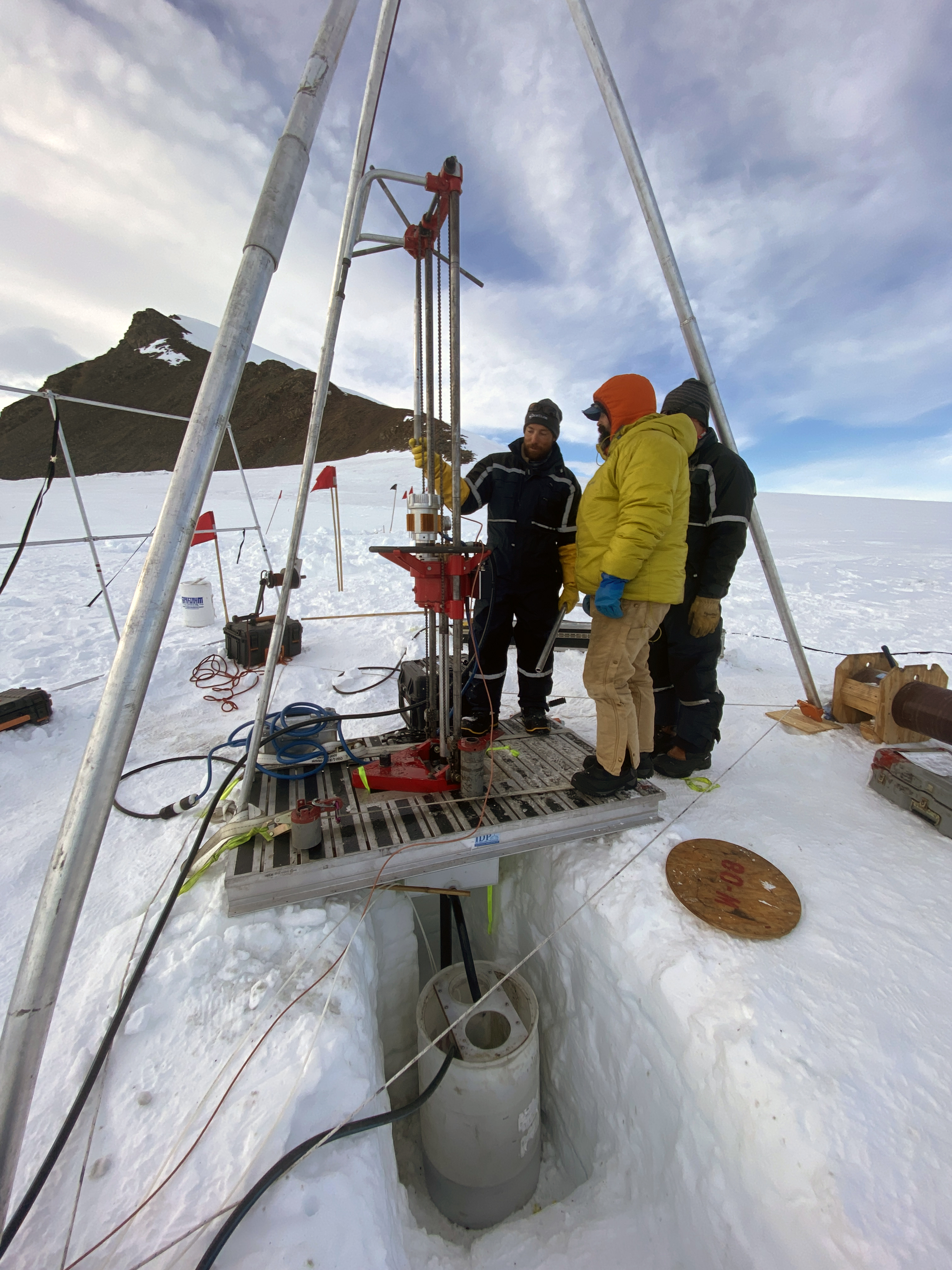

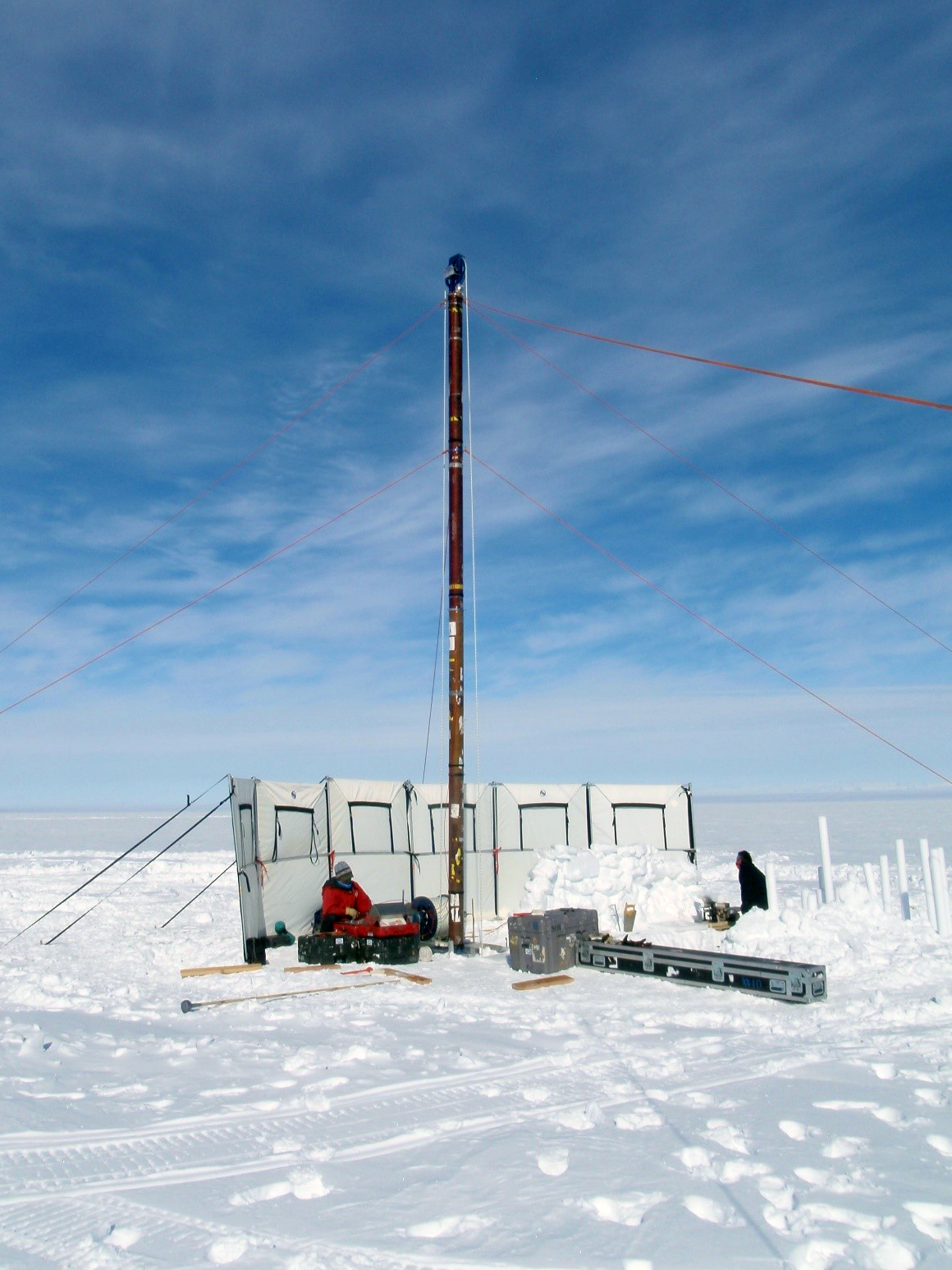

(1) The Geological History Constraints on the Magnitude of Grounding Line Retreat in the Thwaites Glacier System project (PIs Goehring, Balco, Hall, Campbell; C-443-M; NSF award 1738989) contributes to the joint initiative launched by the U.S. National Science Foundation (NSF) and the U.K. Natural Environment Research Council (NERC) to substantially improve decadal and longer-term projections of ice loss and sea-level rise originating from Thwaites Glacier in West Antarctica. The goal of the project is to obtain geological evidence from the Thwaites-Pine Island Glacier system that will show whether glaciers were less extensive than they are at present, and, if so, when. The project will utilize the Badger-Eclipse Drill and Winkie Drill to obtain subglacial bedrock from sites where ice thickness is dynamically linked to grounding-line position in the Thwaites system (specifically in the Hudson Mountains). Observation of significant cosmogenic-nuclide concentrations in these samples would provide direct, unambiguous evidence for past episodes of thinning linked to grounding-line retreat as well as constraints on their timing and duration.

(2) The Thwaites-Amundsen Regional Survey and Network (TARSAN) integrating atmosphere-ice-ocean processes affecting the sub-ice- shelf environment project (PI Pettit; C-445-M/N; NSF award 1738992) contributes to the joint initiative launched by the U.S. National Science Foundation (NSF) and the U.K. Natural Environment Research Council (NERC) to substantially improve decadal and longer-term projections of ice loss and sea-level rise originating from Thwaites Glacier in West Antarctica. Thwaites and neighboring glaciers in the Amundsen Sea Embayment are rapidly losing mass in response to recent warming and related changes in ocean circulation. The processes driving the loss appear to be warmer ocean circulation and changes in the width and flow speed of the glacier, but a better understanding of these changes is needed to refine predictions of how the glacier will evolve. One highly sensitive process is the transitional flow of glacier ice from land onto the ocean to become a floating ice shelf. This flow of ice from grounded to floating is affected by changes in air temperature and snowfall at the surface; the speed and thickness of ice feeding it from upstream; and the ocean temperature, salinity, bathymetry, and currents that the ice flows into. The project team will gather new measurements of each of these local environmental conditions so that it can better predict how future changes in air, ocean, or the ice will affect the loss of ice to the ocean in this region. The project will use a 400-meter winch with tower and sheave from the 4-Inch Drill as an instrument installation winch to lower instruments into hot water-drilled boreholes on the Dotson Ice Shelf to measure ocean water properties at locations where warm Circumpolar Deep Water reaches the Thwaites grounding line.

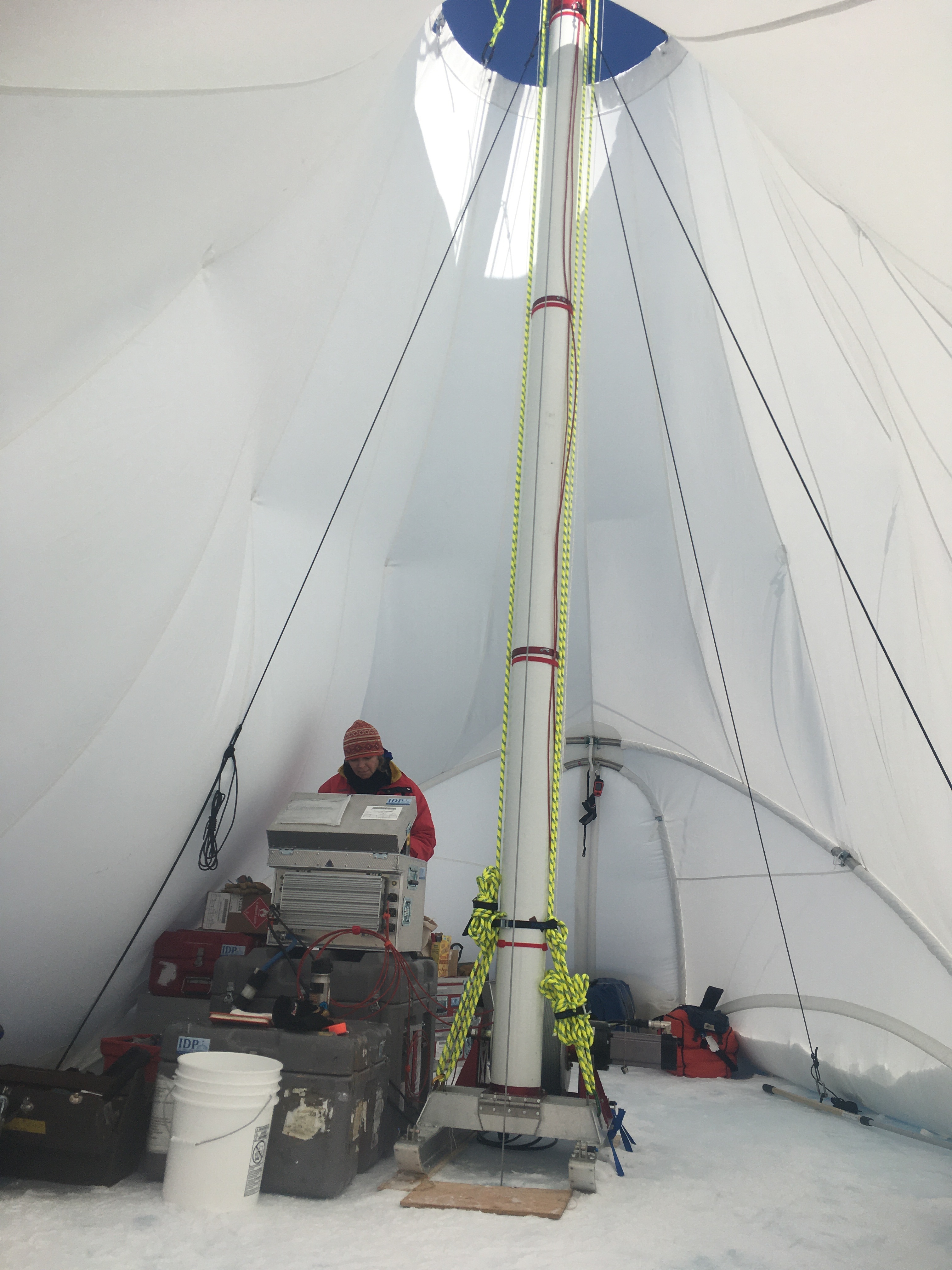

(3) The Collaborative Research: Snapshots of Early and mid-Pleistocene Climate and Atmospheric Composition from the Allan Hills Blue Ice Area project (PIs Higgins, Brook, Severinghaus, Mayewski; I-165-M; NSF award 1744993, 1745006, 1744832 and 1745007) will collect new ice cores from the Allan Hills Blue Ice Area. Bubbles of ancient air trapped in ice cores have been used to directly reconstruct atmospheric composition, and its links to Antarctic and global climate, over the last 800,000 years. Previous field expeditions to the Allan Hills Blue Ice Area, Antarctica, have recovered ice cores that extend as far back as 2.7 million years. These ice cores extend direct observations of atmospheric carbon dioxide and methane concentrations and indirect records of Antarctic climate into a period of Earth’s climate history that represents a plausible geologic analogue to future anthropogenic climate change. Through this project, the team will return to the Allan Hills Blue Ice Area to recover additional ice cores that date to 2 million years or older. The new Foro 400 Drill and Blue Ice Drill will be used to recover the ice cores. The climate records developed from these ice cores will provide new insights into the chemical composition of the atmosphere and Antarctic climate during times of comparable or even greater warmth than the present day.

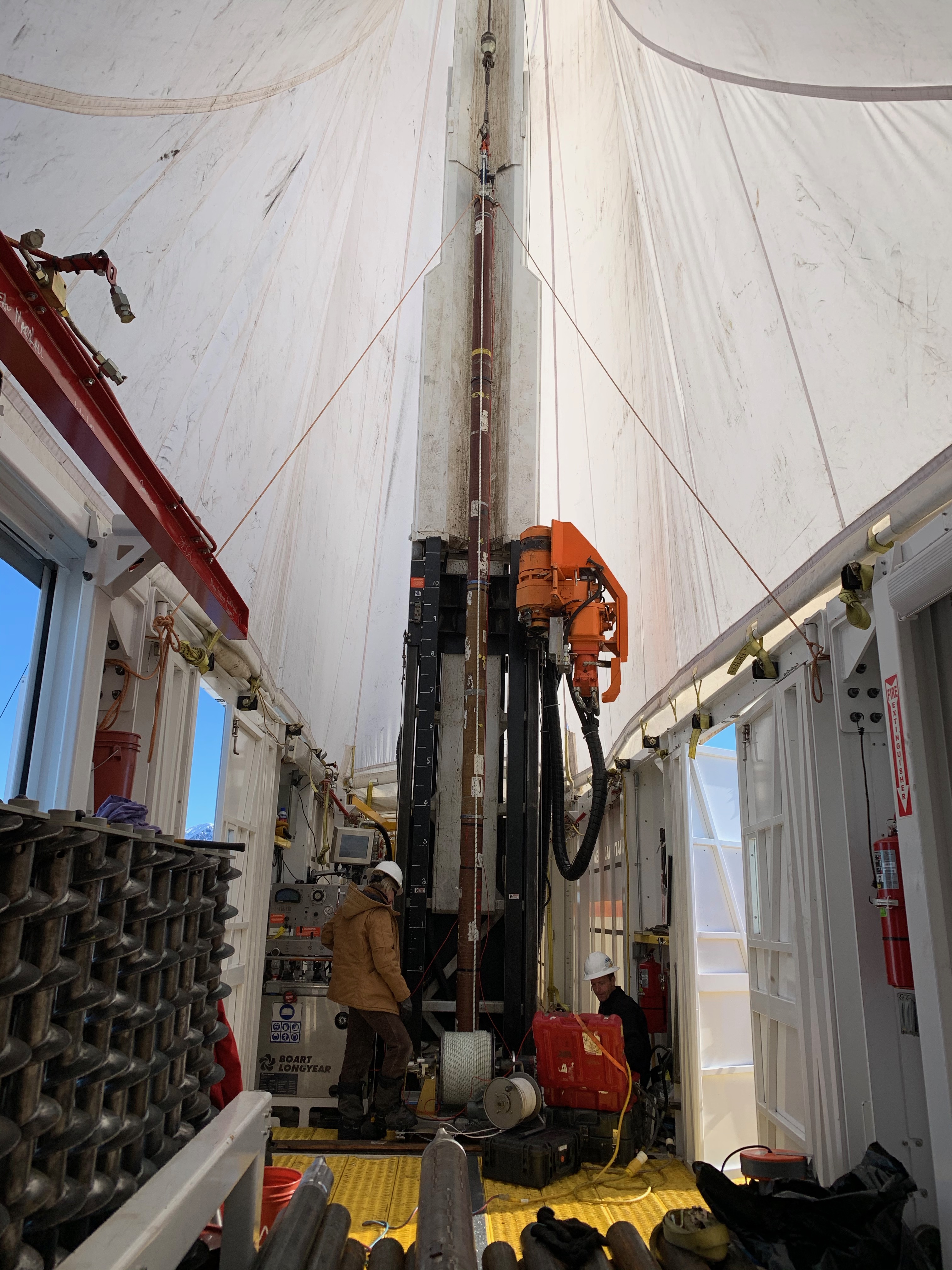

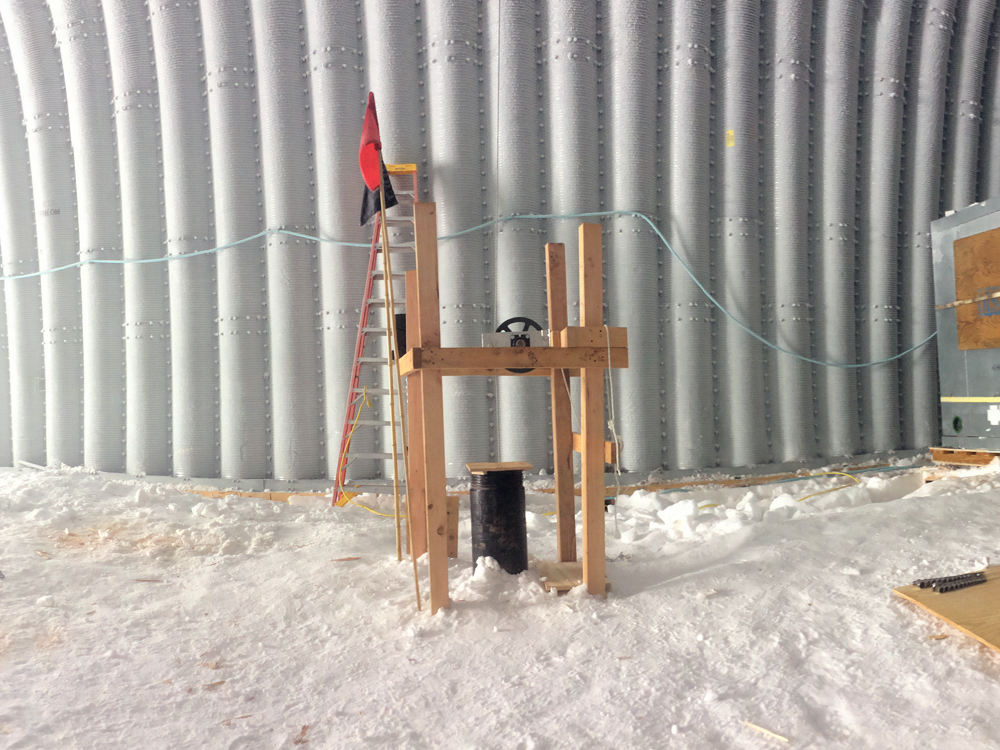

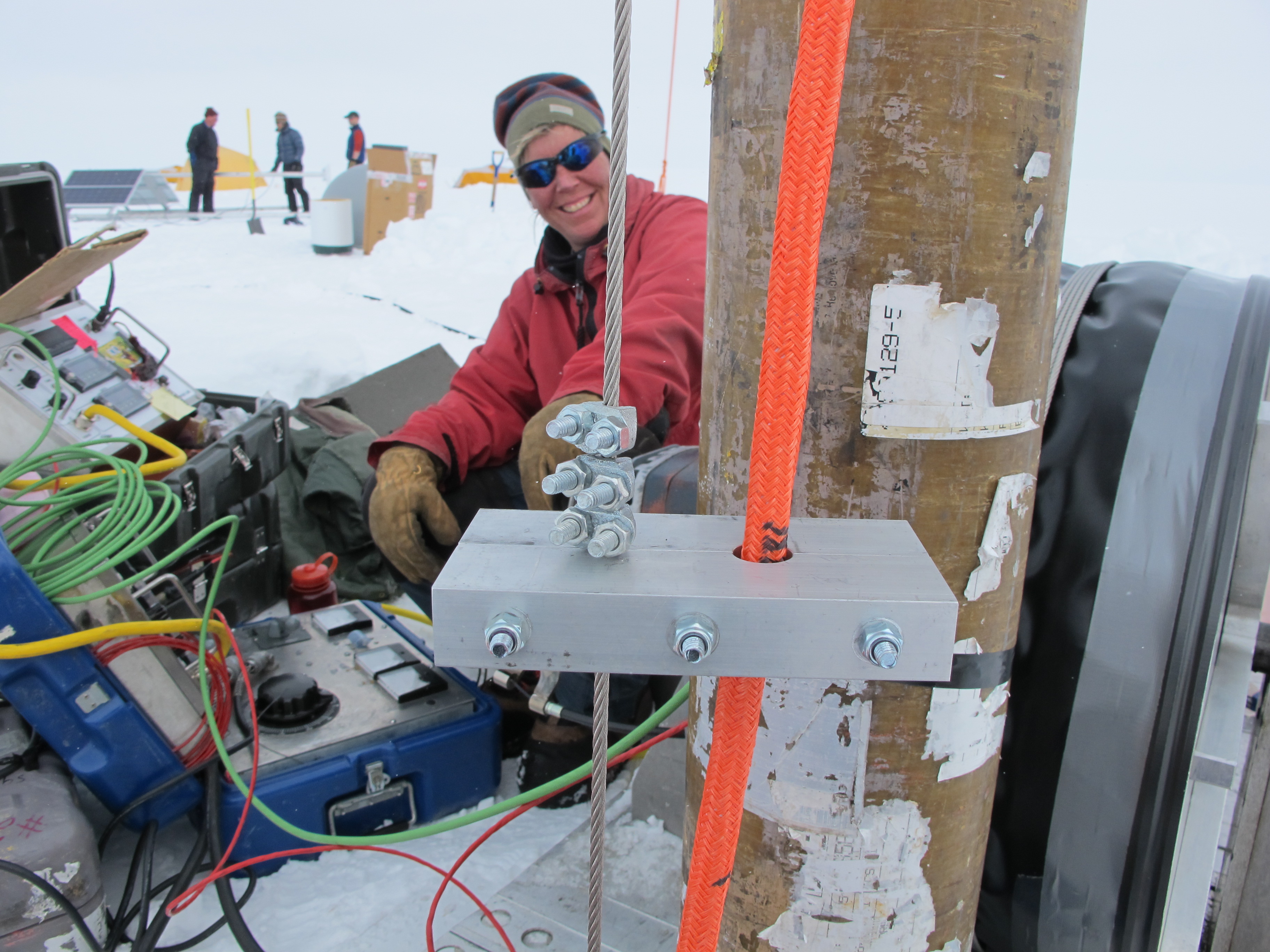

(4) The Phase 2 Development of a Rapid Access Ice Drilling (RAID) Platform for Research in Antarctica project (PI Goodge; D-551-M, D-552-M; NSF award 1419935) will initiate its third Antarctic Field Trial (AFT3) of the RAID drill system – to collect ice and rock samples from a deep ice sheet near Minna Bluff. The RAID drilling system will be put through a complete set of drilling trials, including augering firn, setting a borehole packer, drilling about 600 meters of grounded ice, and obtain samples of ice and rock cores at depth (by wireline rotary coring). All components of the drilling system will be tested and evaluated. The 4-Inch Drill will be used to make 2-3 meters of smooth-walled borehole just below the firn-ice transition, at a depth of approximately 70 meters, to field test the setting of the borehole packer. The Intermediate Depth Logging Winch will be used to field test a borehole dust logger in selected boreholes produced this season at Minna Bluff.

(5) The Management and Operations of the IceCube Neutrino Observatory 2016-2021 project (PIs Halzen and Hanson; A-333-S; NSF award 1600823) will utilize the Intermediate Depth Logging Winch to lower a series of optical+UV and radio sensor packages into the South Pole Ice Core (SPICEcore) borehole to the full depth of the hole (1751 m). The science goals include measurements of the radio absorption length of the ice from 100-1000MHz, radio birefringence in the ice, and ice index of refraction, all measured as a function of depth and ice temperature. The science team is interested in the optical scattering, absorption lengths, and luminescence as a function of depth and optical wavelength from the visible into the ultraviolet.

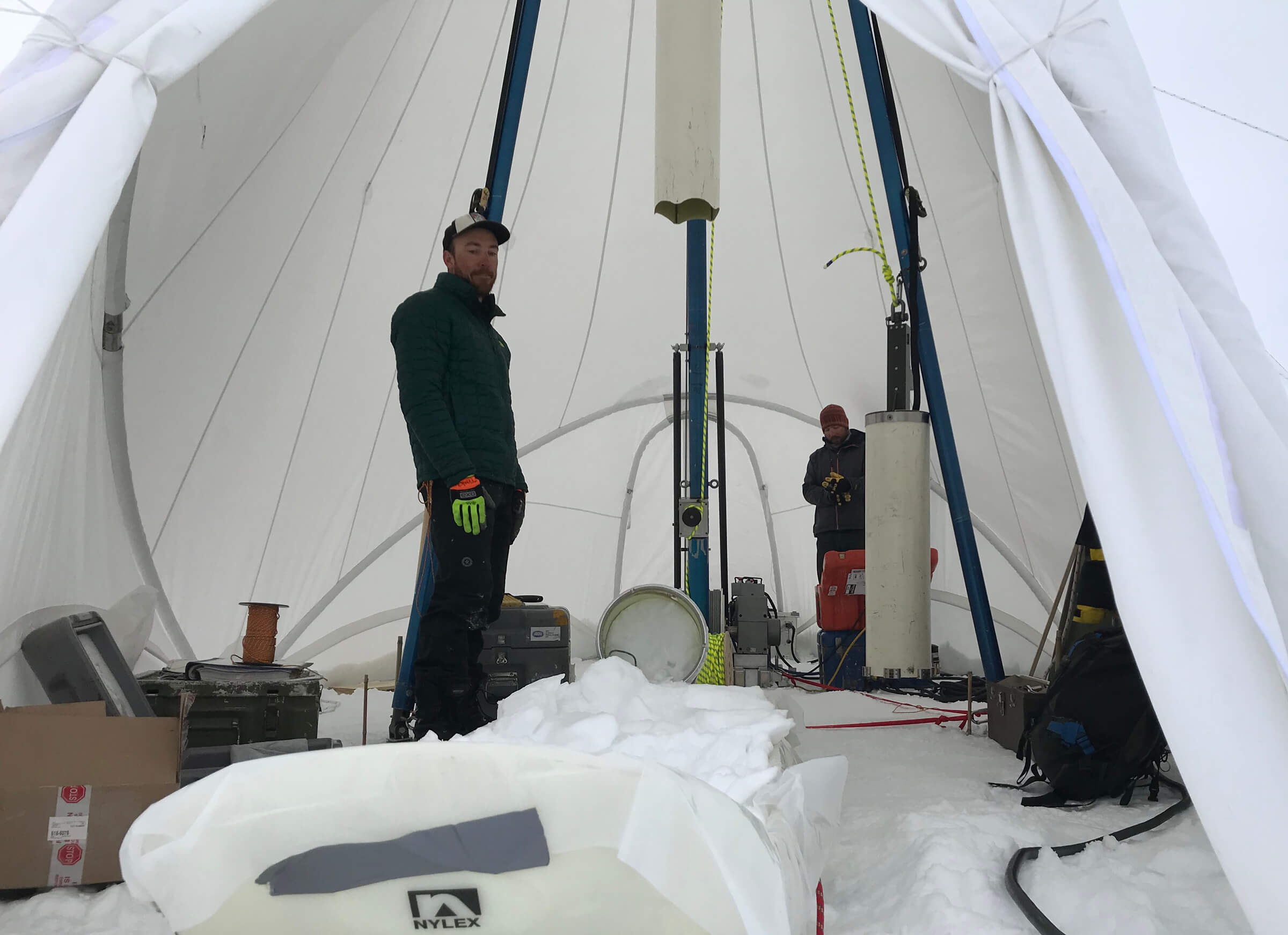

Successful Support of 2018-2019 Antarctic Law Dome Project

IDP deployed engineers Tanner Kuhl and Grant Boeckmann for the jointly-supported NSF and Australian Antarctic Division (AAD) Law Dome Project. IDP worked for several years with PI Vas Petrenko and the AAD to plan for an ambitious amount of ice coring using three IDP drill systems: a Badger-Eclipse Drill, a 4-Inch Drill, and the Blue Ice Drill. Despite challenging weather conditions, over 1,000 meters of ice core was drilled across six boreholes, surpassing the original science objectives. This project also represented the first deployment of the newly-acquired Blue Ice Drill tent. Project participants report that the tent performed well, even during high winds, allowing for continued operations during inclement weather.

Equipment Updates (2018 Summer)

Foro 3000 Drill

IDDO continued initial development tasks for the Foro 3000 Drill system during the third quarter. Detailed design of the winch drum and level wind are in process. Sizing calculations were made and a design initiated for the chip melter system. Sonde assembly drawings were largely completed. Design work is expected to ramp up in the fourth quarter in preparation for a Detailed Design Review in late September.

Foro Drill

Anti-torque section assembly was largely completed and motor section assembly was initiated on the Foro Drill. Cabling was completed for the control box and drill motors were ordered. Shipping cases were received for the sonde, tower, and winch. Cutter head assemblies, spare cable terminations, and anti-torque slip rings were also received. Some assembly and testing have been delayed in light of work on higher priority projects, but procurements are largely complete.

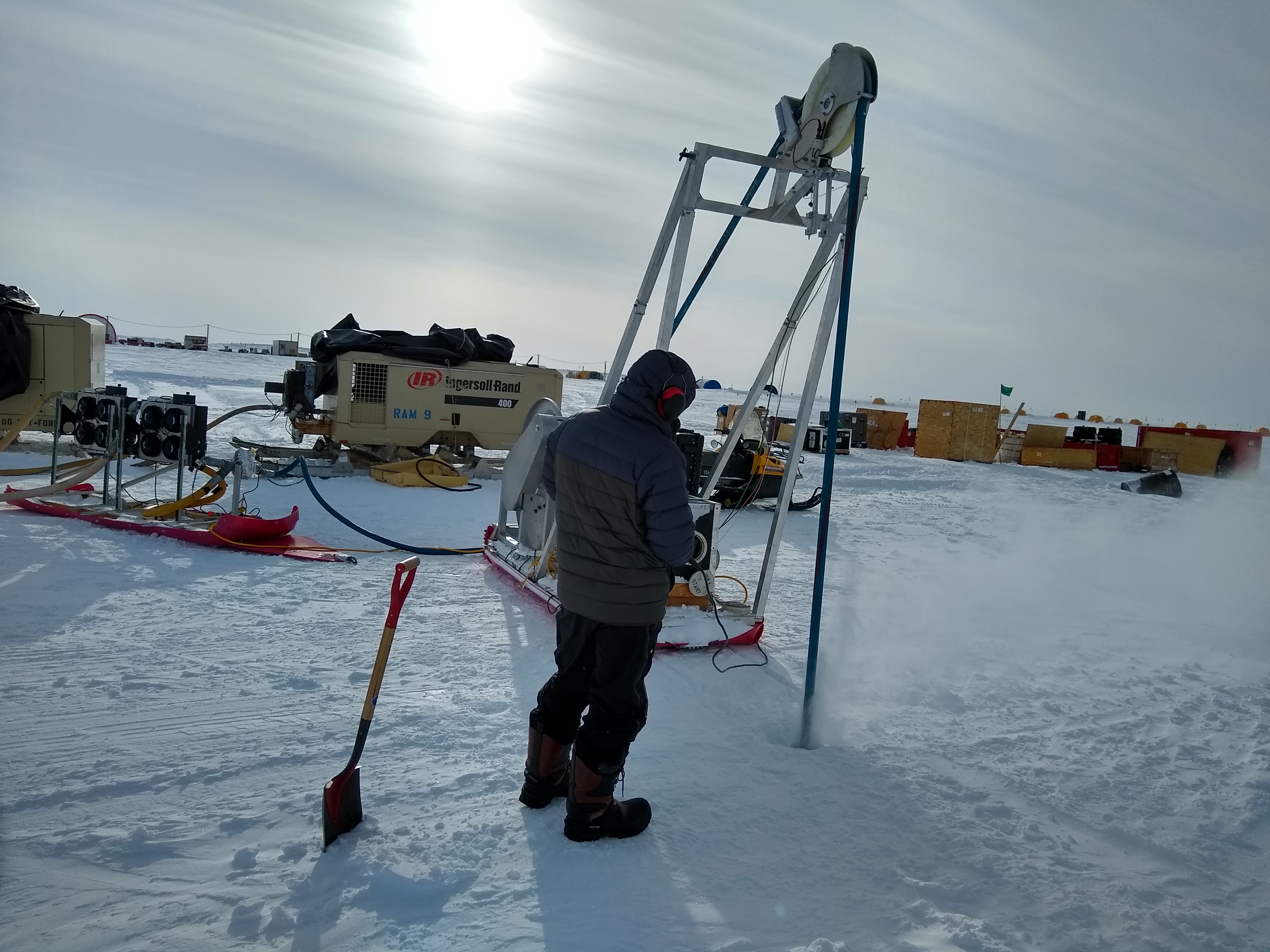

Rapid Air Movement (RAM) Drill

Continued acceleration of RAM Drill design, procurement, and in-house testing. The system was prepared, packed and shipped to Scotia, NY in late June. In early July, IDDO received an Expedition Permit from the Government of Greenland, and a two-week field test was subsequently completed at Camp Raven in late July.

Intermediate Depth Drill

Models and drawings were completed for the winch cable terminations and spare cable termination kits were received for the Intermediate Depth Drill. System maintenance continues at a slow pace, as does the testing and troubleshooting of the Mage Controls components. The components, returned to Mage Controls at the end of the second quarter, are expected back at IDDO early in the fourth quarter.

Winkie Drill

Borehole casing was specified and purchased in preparation for the Winkie Drill's first use in West Antarctica at a drill site with overlying firn. IDDO sought information from international colleagues regarding methods to seal the bottom of the casing to the ice. Packer components, benchtop testing for compressed air inflation, and detailed models of packer components were also researched.

Blue Ice Drill (BID)

Maintenance and upgrade tasks were largely completed during the quarter for the BID-1. The drill was subsequently cleaned, packed and shipped for the upcoming Law Dome project in Antarctica. IDDO continued communication with BID tent vendor Fabricon. Engineer Tanner Kuhl visited the vendor's location in mid-July to review the design and progress thus far, and the tent was completed in mid-August.

Thermal Drill

The Engineering Requirements document for the Thermal Drill was approved and released. IDDO engineers worked to identify, procure and test some thermal and power limiting materials and components during the quarter. New heat rings were specified, as the old model is now out of production, and a number of new rings were ordered late in the quarter.

Hand Augers

Planned modifications for the cleat and locking break components of the SideWinder units were implemented on all five kits in inventory. Equipment was returned from Svalbard and Greenland and was repaired as needed. Orders were subsequently placed for replacement of a few components that were stuck in the ice during the 2018 Arctic fieldwork.

4-Inch Drills

Maintenance was completed for the 4-Inch Drill system that returned from Antarctica. One core barrel set was modified to match beneficial modifications made to another barrel set in inventory. An improved cable keeper for the crown sheave was designed, fabricated and implemented.

Eclipse Drills

A more robust top cover and new side panels were installed on the Eclipse Drill traversing system. Beneficial updates were made to the Operator's Manual. Small tools such as strap wrenches and sharpening stones were purchased for use in the field.

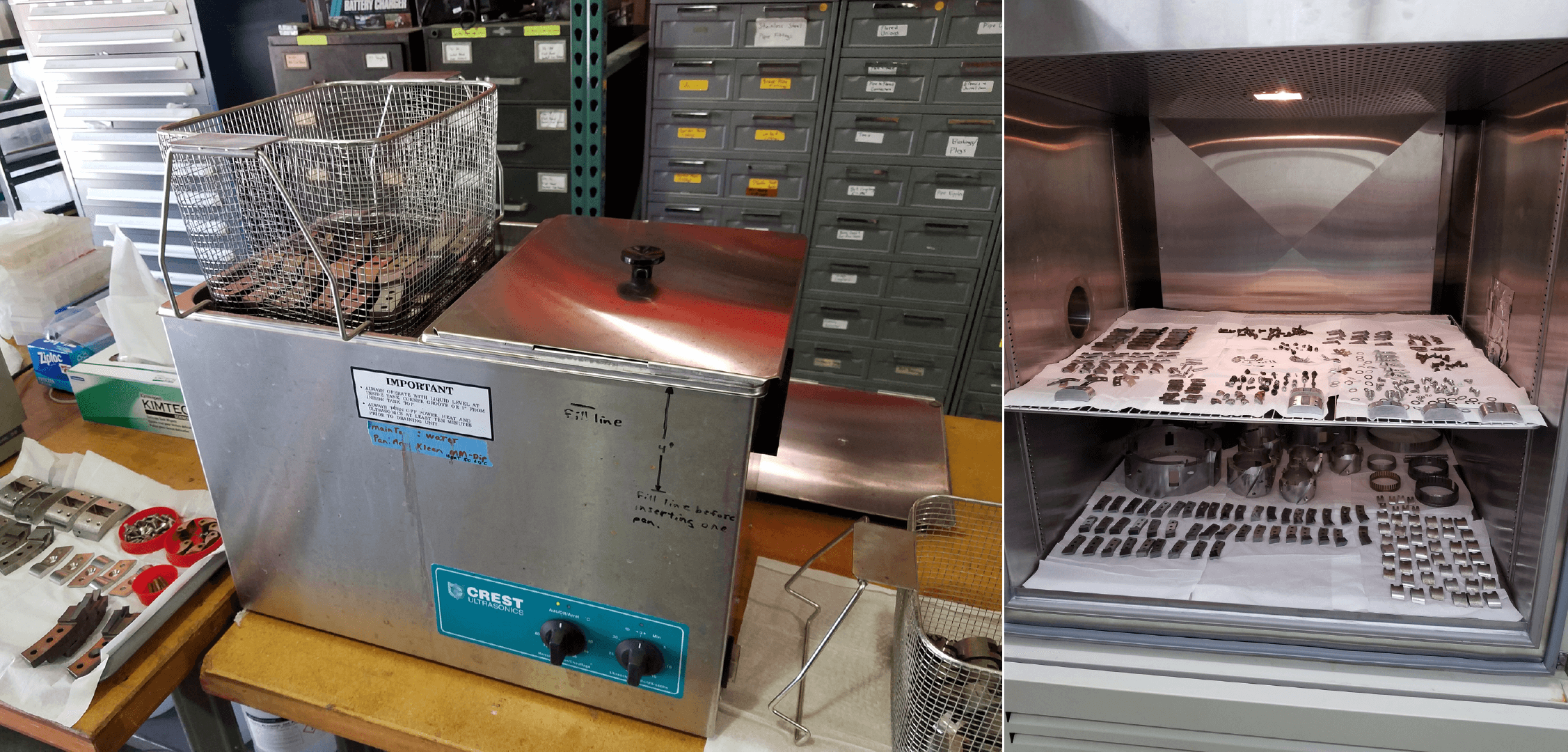

Antarctic Cargo Preparation Commences for Law Dome Project

In early June, IDDO turned its attention to cargo preparation for the Law Dome field project (PI Petrenko). IDDO staff have been participating in regular teleconferences with the science team and the Australian Antarctic Division to prepare for the joint U.S.-Australian supported fieldwork. At IDDO, an extensive cleaning protocol was implemented for a 4-Inch Drill, a Badger-Eclipse Drill and the Blue Ice Drill, to ensure carbon-free sampling during the upcoming Law Dome project. Drill parts underwent ultrasonic cleaning in acetone, followed by further cleaning in ethanol and deionized water. Metal parts such as coring heads, cutters, etc. were further baked overnight in an environmental chamber. The cargo was subsequently shipped on July 26, 2018, to Port Hueneme, CA, eventually bound for Hobart, Tasmania.

IDDO Completes Support of 2017-2018 Antarctic Season

IDDO deployed four separate drilling/logging systems for use during the 2017-2018 season, along with three IDDO equipment operators.

IDDO engineer Tanner Kuhl accompanied the 4-Inch Drill and Deep Logging Winch to Minna Bluff for the Rapid Access Ice Drill (RAID) second Antarctic field trial (AFT2; PIs Goodge and Severinghaus; D-551-M) project. The 4-Inch Drill was used successfully to drill one hole to 131 meters, with firn air samples collected by the science team (PI Severinghaus; D-551-M) from nine separate depths. The 4-Inch Drill coring activities found the firn-ice transition at Minna Bluff to be at approximately 82 meters depth, providing valuable firn-ice transition data for the nearby RAID AFT2 operations. IDDO's Deep Logging Winch was deployed to allow for logging of the RAID AFT2 boreholes using Ryan Bay's optical logging tool. The Deep Logging Winch was ultimately not used during the RAID AFT2, however, as the RAID system was unable to complete a hole to depth. While development, fabrication and testing of the RAID system is being conducted by DOSECC Exploration Services LLC and is not an IDPO-IDDO activity, Kuhl's deployment to Minna Bluff also gave him the opportunity to drill with the RAID field team, learn about the RAID system operation, and provide trouble-shooting support to the RAID team.

The Intermediate Depth Logging Winch was sent to the South Pole, where it was used successfully by the Askaryan Radio Array (ARA) field team (PI Karle; A-107-S) to log the existing South Pole Ice Core (SPICEcore) borehole to gather physical properties data as well as radio properties and ARA calibration data. IDDO engineer Chris Gibson joined the ARA field team at the South Pole this season to gain valuable hands-on experience with their hot water drilling operation.

The Winkie Drill successfully completed its second field season, this time in Ong Valley (PIs Putkonen and Morgan; G-192-M). Drill upgrades made in Madison following the previous project in the Ohio Range proved successful, and IDDO engineer Grant Boeckmann was able to collect quality mixed media cores consisting of ice, silt and rock. While the original project goal was to collect three cores from two separate sites (six cores total), the ice encountered contained much more sand, silt and rock than the PIs anticipated. One core was collected at each of the two sites, with one core to 10 meters and one to 12 meters depth. The higher debris content proved very useful for the science goals, reducing the number of holes needed.

IDDO also supported six hand auger projects during the 2017-2018 field season through the provision of Hand Auger and Sidewinder equipment.

2016-2017 Antarctic Field Season Wraps Up

In addition to the two sub-glacial rock drilling projects described above, IDDO successfully supported three projects at or near the South Pole, and one at WAIS Divide, during the 2016-2017 Antarctic field season. South Pole Ice Core (SPICEcore; PI Murat Aydin; I-164-S) operations were completed in just three years at South Pole, with 1751 meters of ice core drilled, one round of borehole logging (PI Ryan Bay; I-194-S) with the Intermediate Depth Logging Winch completed, and all equipment has now been removed from the site. Engineers Jay Johnson and Josh Goetz completed all remaining activities this season, with help from the science team onsite. Also near South Pole Station, drillers Mike Waszkiewicz and Elizabeth Morton completed a number of holes ranging from 5 to 125 meters depth using the IDDO 4-Inch Drill system (PI Michelle Koutnik; I-193-S). In West Antarctica, despite needing to make a last-minute operator change, borehole logging with the Deep Logging Winch was also successfully completed at WAIS Divide (PI Erin Pettit; I-166-M).

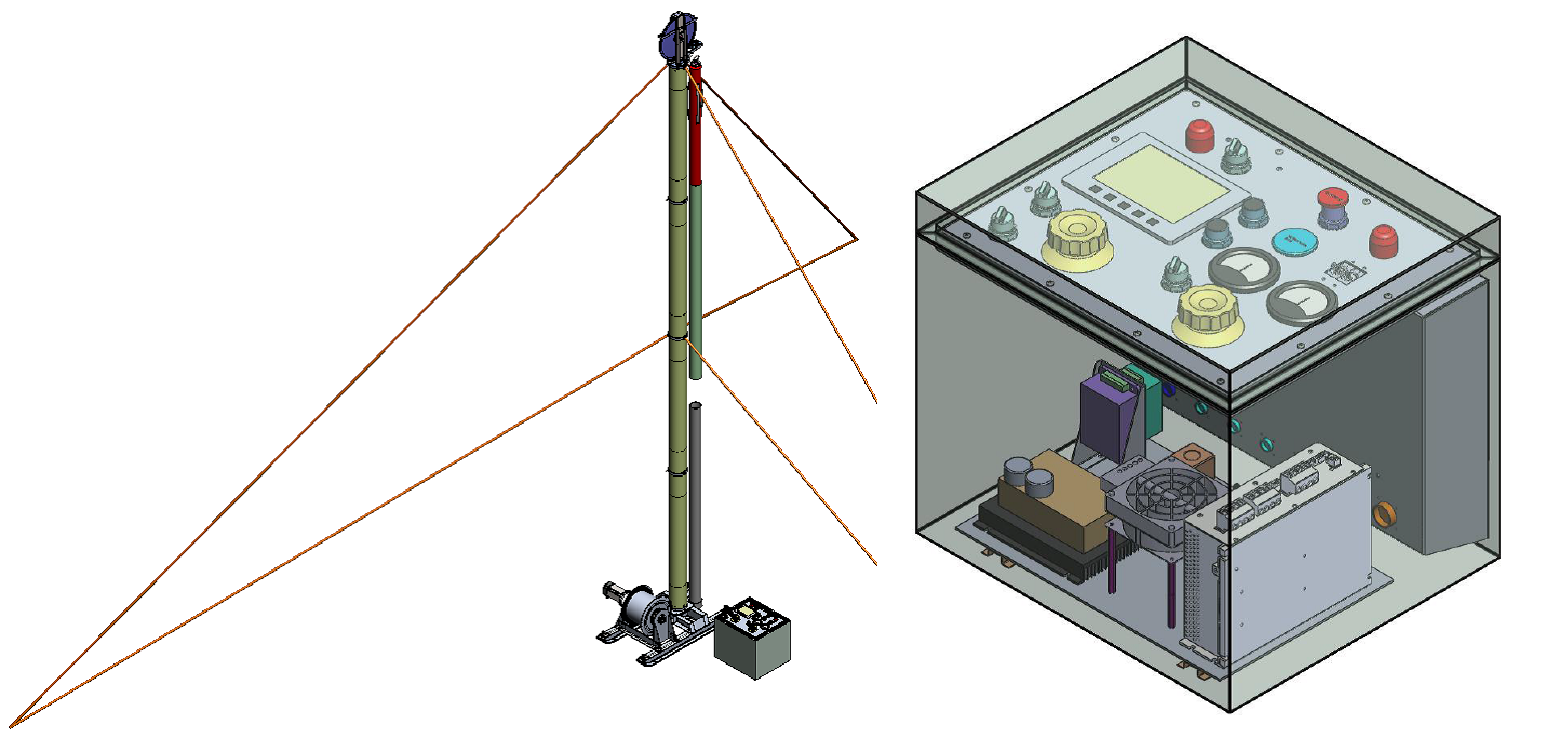

Beneficial Design Upgrades Continue for 4-Inch 'Foro' Drill

During the Second Quarter, IDDO completed the preliminary design of the new 'Foro' Drill System to upgrade the popular, yet aging, 4-Inch Drill equipment. IDDO engineers have utilized feedback from 4-Inch Drill operators to make this new system lighter, more robust, more easily controlled, and more user-friendly. The sonde design is based on that of IDDO's Intermediate Depth Drill (IDD) and the current 4-Inch Drill designs, with certain components being interchangeable with the IDD, including the anti-torque section, motor section, and the cutter head. The designs for the 'Foro' Drill sled, winch, cable, and control system are brand new designs, and the tower is a modified and improved version of the current 4-Inch Drill tower design. The new sled, winch and tower assembly alone offer a 40% weight savings over the current 4-Inch Drill components. In addition, upgrading the control system to include only one comprehensive control/readout box, as opposed to the two separate boxes used by the 4-Inch Drill, will offer an additional 30% weight savings in this area. In March 2015, IDDO circulated a 'Name That Drill' Doodle poll to encourage IDPO and IDDO team members to vote on a name for the new components, so that distinguishing between the old and new equipment would be more straightforward. The name 'Foro' was selected, and is Latin for "to make a hole, pierce or to bore". On the last day of the Second Quarter, April 30th, IDDO held a Preliminary Design Review where the engineers presented the new system design and future plans for the 'Foro' Drill.

The major design upgrades for the 'Foro' Drill include:

- Redesign tower and winch to be lighter/smaller

- 5.7 mm diameter steel electromechanical winch cable, same as used on the IDD Drill (current 4-Inch Drill cable is 13mm in diameter)

- New cable weight is 13.1kg/100 m (current 4-Inch Drill cable weight is 17.1kg/100 m)

- Upgrades for wet conditions

- New sealed motor section – submersible in drilling fluid or water (current 4-Inch Drill is not submersible)

- Upgraded control system

- Drill and winch motors will be able to be run simultaneously

- Off-the-shelf motor controllers

- Reduced weight, compared to the existing 4-InchDrill control boxes

Scientific Drilling (2013 Arctic field season)

Denali (PI Osterberg)

IDDO provided driller Mike Waszkiewicz and a Eclipse Drill for PI Erich Osterberg's coring project in Denali National Park. Two holes were completed down to a depth of 208 meters each, resulting in excellent core quality. A new solar and wind system capable of powering the Badger-Eclipse Drill proved successful on its maiden field project. Such clean drilling efforts were praised by National Park Service staff and will continue to be utilized in the future.

Greenland Aerosol and Greenhouse Gases Core (PI McConnell)

Despite being forestalled by weather in previous attempts to drill ice cores on Tunu Glacier in Greenland several years ago, IDDO driller Bella Bergeron and the science field team were able to recover successfully over 350 meters of ice core during the month of May. Using an IDDO 4-Inch Drill, one hole was completed down to 213 meters while a second hole was completed down to 141 meters.

Greenland Cosmogenic C-14 Cores (PI Petrenko)

A team of three IDDO drillers, Lou Albershardt, Mike Jayred, and Tanner Kuhl, accompanied by a field science team was able to successfully utilize a Eclipse Drill to drill two holes for firn air pumping studies outside of Summit Station, Greenland. One hole was completed to 90 meters and another completed to 102 meters. In addition, the IDDO-designed Blue Ice Drill was put to the test to determine its ability to collect firn cores. The Blue Ice Drill is expected to undergo several modifications over the next year to enable additional firn coring in Greenland as well as to extend its depth capabilities in both firn and ice.

Greenland Perennial Firn Aquifer (PI Forster)

As a follow up to a previous project conducted by PI Rick Forster in SE Greenland, IDDO provided driller Jay Kyne and the IDDO Thermal Drill to drill through the firn aquifer layer. Two holes were completed down to 60 meter and 25 meters, respectively, each allowing the deployment of a thermistor string through the aquifer.

McCall Glacier Cores (PI Nolan)

PI Matt Nolan completed his third season of a three-year ice coring project on McCall Glacier in Alaska. Throughout the project, Nolan utilized both a 3-Inch and 4-Inch PICO Hand Auger to retrieve shallow core samples.

Summit Shallow Core Array (PI Noone)

PI David Noone's field team deployed late in the third quarter to continue their collection of shallow ice cores near Summit Station. To support this work, IDDO again provided a PICO hand auger and a new IDDO hand auger as well as a Sidewinder power drive system. This year marks the third year of IDDO's support of the four-year project.

Multidisciplinary Science on the Greenland Ice Sheet is Enabled by Agile Ice Core Drills

Despite battling bitter winds and cold April temperatures in Greenland, P.I. Rick Forster's Arctic Circle Traverse (ACT) field team successfully drilled and processed over 200 meters of ice core at four traverse sites in Greenland under the leadership of IDDO Lead Driller, Terry Gacke. The cores may yield insights on snow accumulation. Meanwhile, in the center of the ice sheet, the field team for P.I.s David Noone and David Schneider drilled a shallow core array near Summit Station, Greenland using an IDDO PICO 4-inch hand auger system and Sidewinder kit. At Raven Camp on the ice sheet, activity focused on a detection system for ice sheet movement; a 300-meter borehole was drilled and a seismometer successfully deployed in May for P.I. Kent Anderson's Greenland Ice Sheet Monitoring Network (GLISN) project. Under the leadership of IDDO Lead Driller Bella Bergeron, IDDO driller Terry Gacke, IDDO engineer Tanner Kuhl and the GLISN science team utilized the 4-Inch Drill system winch to control descent of the seismometer. In addition, three solar arrays were constructed, surface seismometers buried, wind turbines and GPS antennas erected, and interconnecting cables buried.