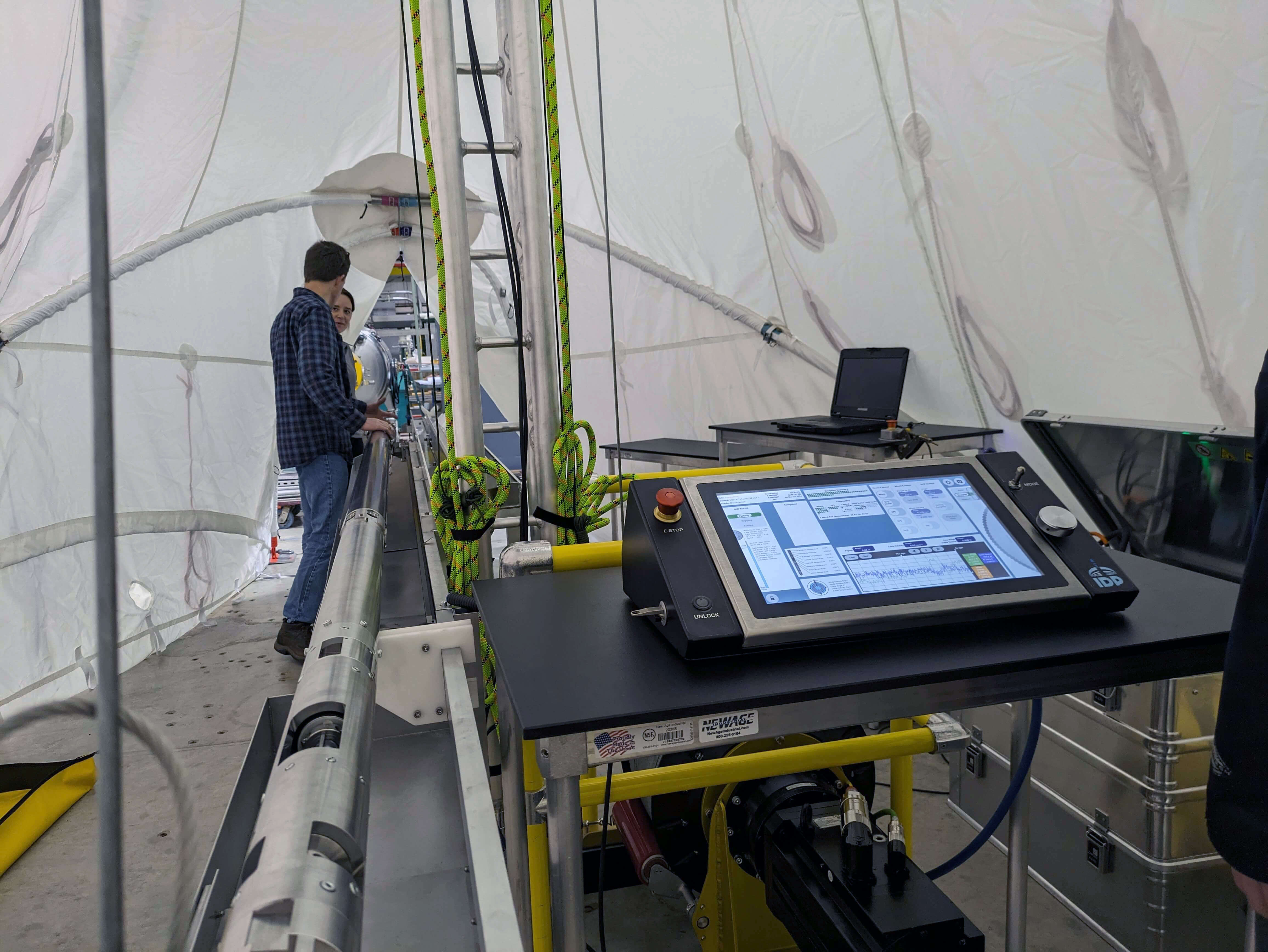

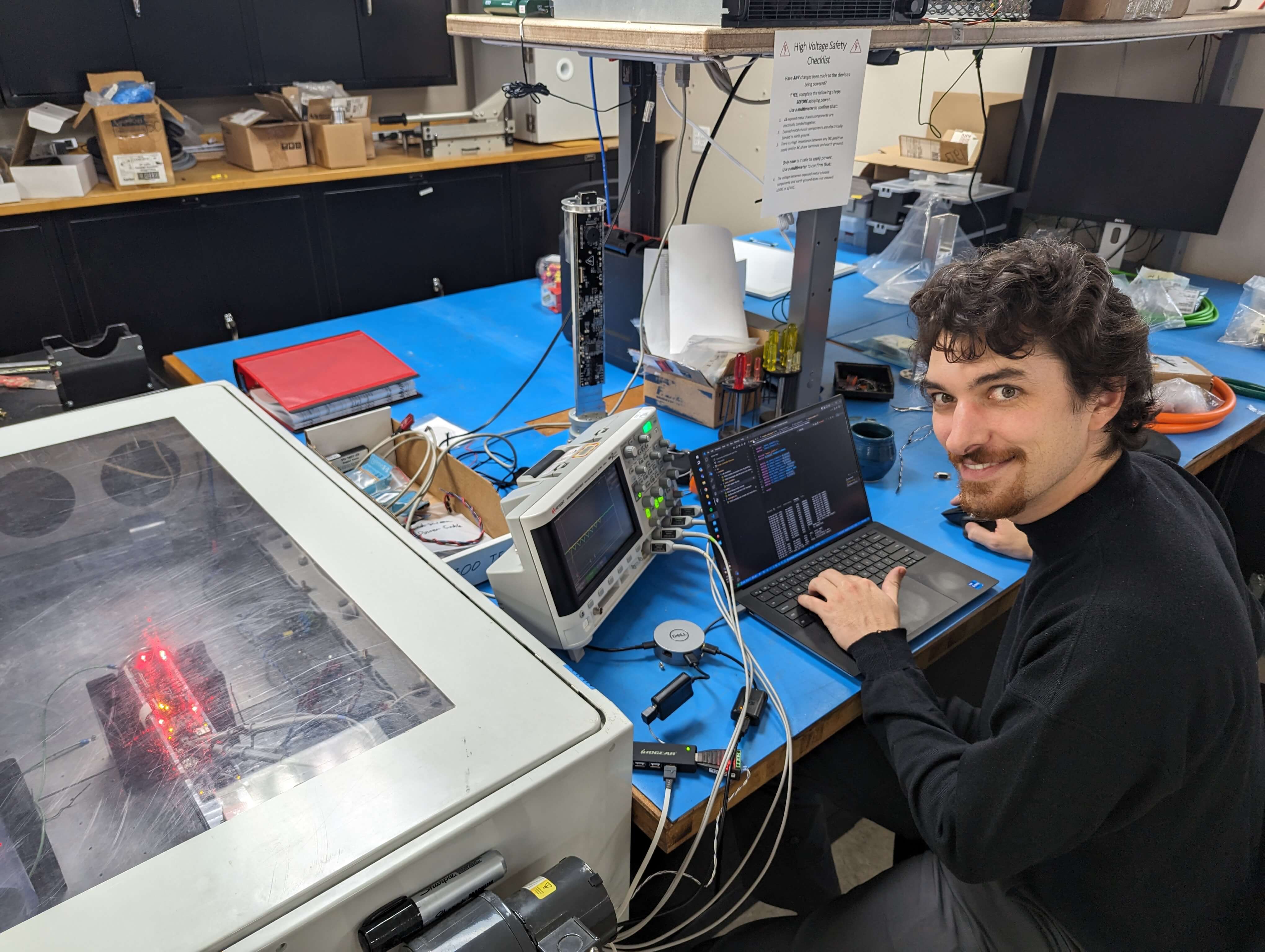

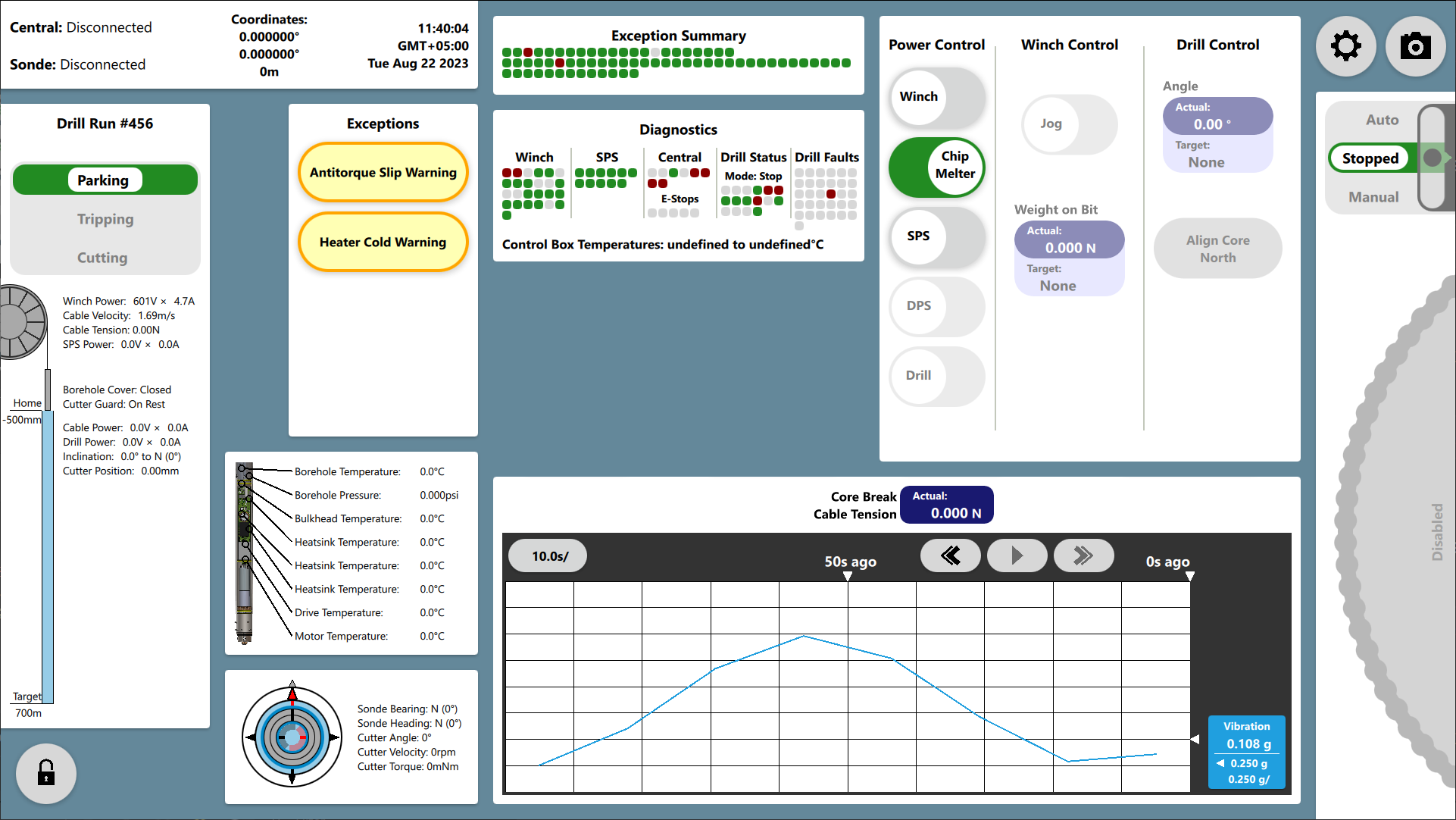

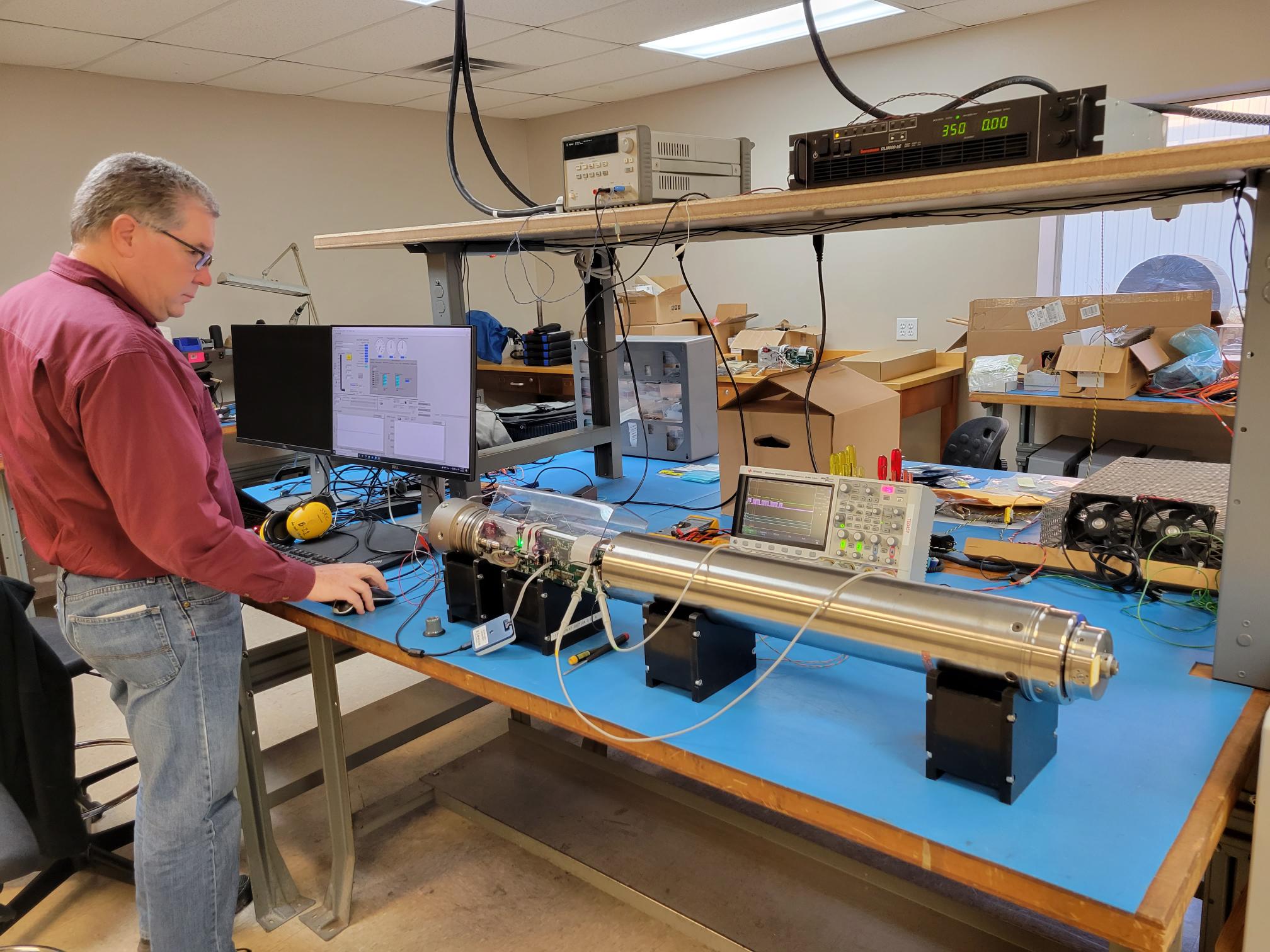

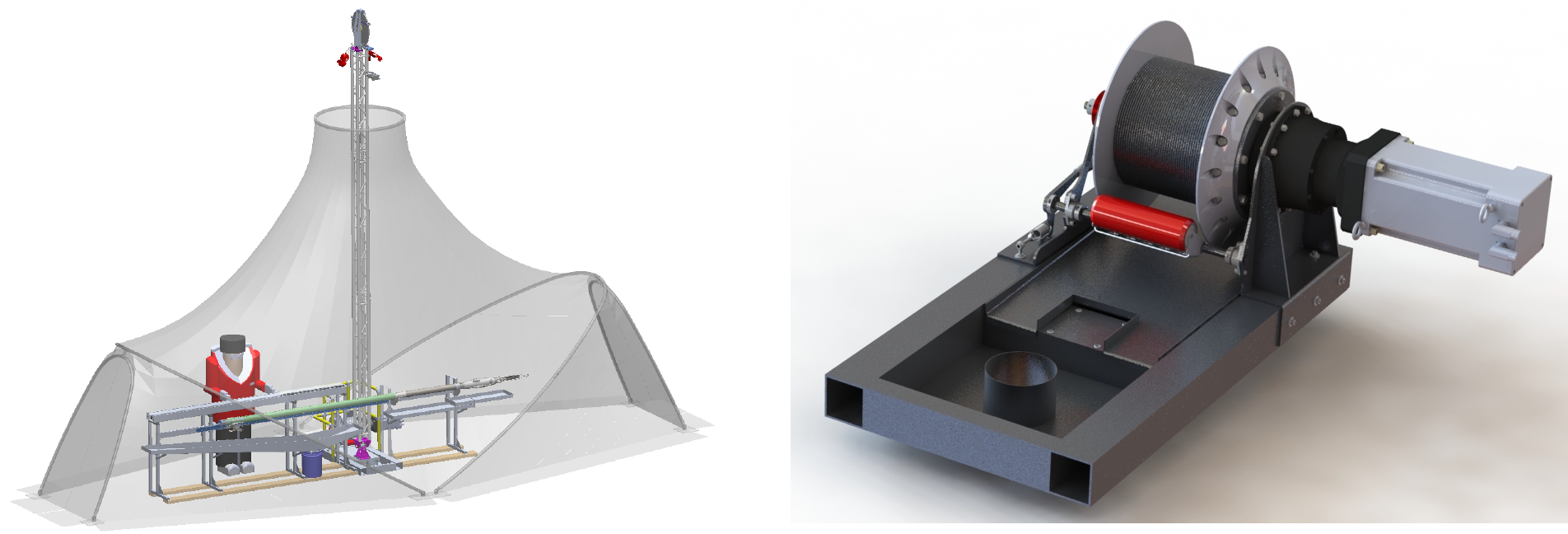

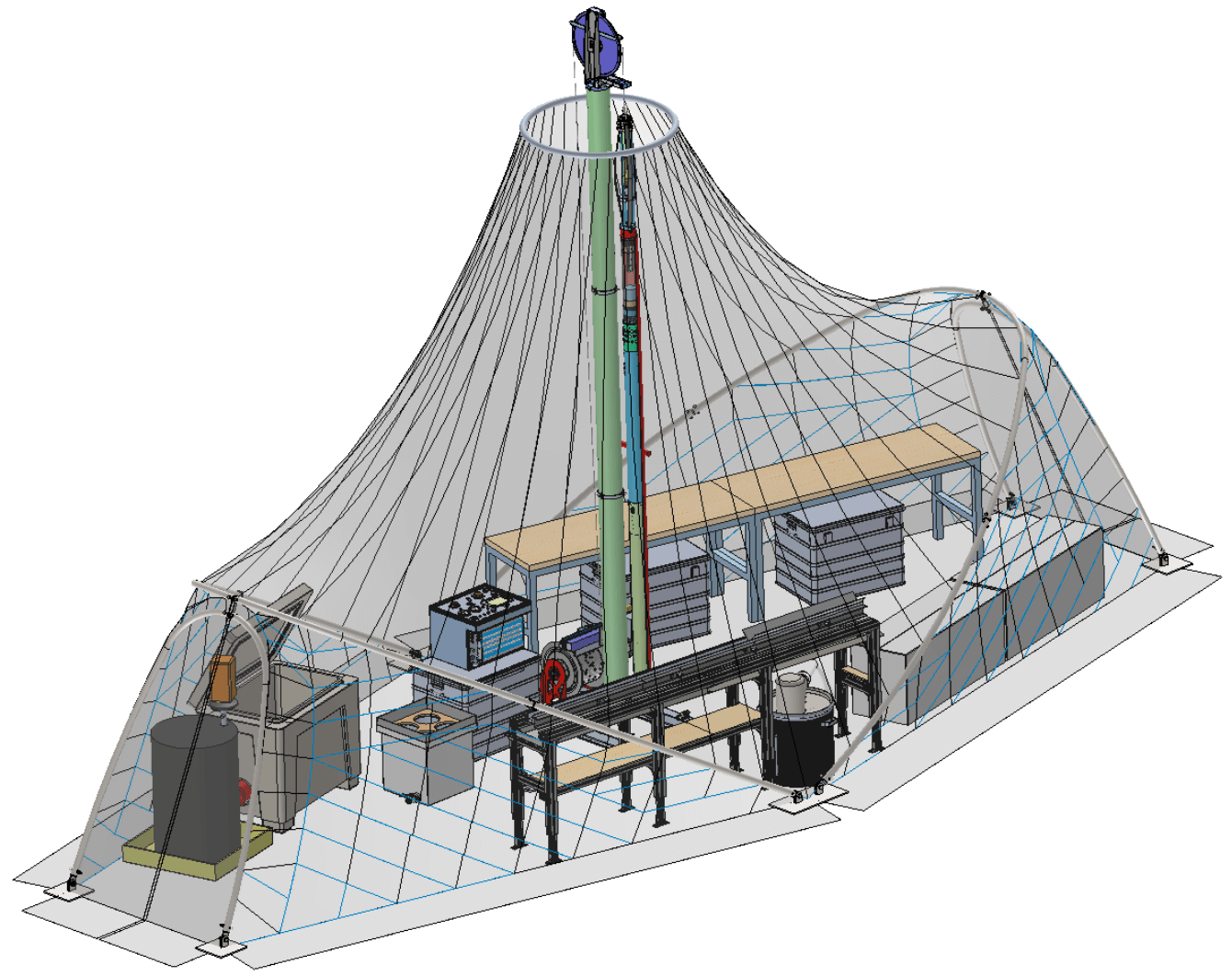

In February and March, IDP engineers spent some time at the UW-Madison Physical Sciences Lab (PSL), putting the 700 Drill winch and control system through its paces. The winch and tower were set up over a cased hole in the ground, and a portion of the drill sonde and a weight were attached to the cable. IDP Electrical Engineer Umberto Stefanini spent several days inside an Eskimo work tent working to test and troubleshoot the control system. Following the outdoor testing, the drill tent was set up inside an adjacent facility at PSL. In April, the drill was set up at the IDP facility to facilitate final in-house testing of the control software, slide rail assembly for laying the drill down, and the core handling and chips/fluid handling trays and assemblies. The drill was disassembled in late April, and packing began for shipment to Scotia, NY, in early May. The drill will be tested and used at Summit Station in June and July to support PI Eric Saltzman’s project.

700 Drill

New 700 Drill System Ready for Action

Drill Development and Maintenance/Upgrade News

Development of the 700 Drill continued at an excellent pace. The control box and console wiring were completed, and the control box was powered up and tested. The design of the chip bailer continued, and sonde components like the outer tube, hollow shaft, and core barrel were fit-checked. IDP met with personnel at the UW Physical Sciences Lab (PSL) to coordinate the testing of subsystems in the PSL test well. Work continued on the sonde electronics. The motor torque test stand was assembled, and engineers immediately began gathering and analyzing data. Orders were placed for core processing and fluid handling system components. The drill cable was successfully spooled onto the winch. The first use of the 700 Drill is scheduled for the summer of 2024 in support of PI Eric Saltzman’s molecular hydrogen (H2) project (NSF award 2243540) at Summit, Greenland.

The Engineering Requirements document for the BASE (Basal Access and Subglacial Exploration) Drill system was finalized and approved. Drill rod was ordered and received. Jay Johnson and Elliot Moravec traveled to Multi-Power Products Ltd in Kelowna, BC, in February for drill acceptance and operational training. IDP expects to receive the drill in Madison, WI, in March or April, and will work to design the auxiliary components for use of the drill in ice in the polar regions.

In preparation for the second GreenDrill season, a level wind option was purchased for the Agile Sub-Ice Geological (ASIG) Drill, as well as Kubota engine spares, drill rod end caps, rod scraper rings, Geoblock for the drill tent and generator tent flooring, and a replacement flow jet pump. IDP engineers also worked to design improvements for the ASIG Drill chip handling and filtration system. The Winkie Drill packer and the water swivel seal were tested, and filter socks, casing centralizers, and full-face and impregnated bits were purchased. Additional Winkie Drill casing was ordered and received to account for GreenDrill firn depth uncertainty, and work on a new insulated filtration tank was completed.

Work continued on new outer tubes for the Foro 400 Drill, and components for a new truss tower were received.

Drill Development and Maintenance/Upgrade News

Assembly of the new 700 Drill is in full swing at IDP in Madison, WI. Mechanical assembly of the sonde is nearly complete, from the anti-torque section down to the cutter head. The control box and console are currently being wired, and electronics testing is underway. Shipping cases were ordered and received, and designs for the core handling and fluid/chips processing systems are now complete.

IDP Engineers revisited the Deep Logging Winch to mitigate electromagnetic interference (EMI) issues previously witnessed in the field with several logging tools provided by community scientists. Through careful investigation and comparison with a winch at the UW Physical Sciences Lab, noise and communication lapses have been successfully mitigated by installing two filters and cleaning of slip ring contacts. The winch is now ready for issue.

Good progress is being made in preparing the Winkie and ASIG drills for the second season of the GreenDrill project in northeast Greenland in spring 2024. Maintenance was completed on the Winkie Drill packer and drive head and air compressors for the Winkie and ASIG drills. New core barrel components were ordered, received, and tested for the Winkie Drill to improve clearances when drilling in clay and mixed media, and a new slip foot clamp was implemented and tested.

New 700 Drill Takes Shape

Over the past ten months, IDP electrical and mechanical engineers have worked hard to bring the detailed designs for the 700 Drill to life. Equipment designs were finalized, engineering drawings completed, components ordered, and assembly begun. The winch and tower were fully assembled in Madison, and the electronics hardware and software also made excellent progress. Control system mechanical and electrical features were finalized, and work was initiated on final auxiliary systems such as core handling and chips processing equipment. IDP anticipates the drill will be ready for issue by March 2024.

700 Drill Fabrication Approved

The IDP Science Advisory Board identified in the IDP Long Range Science Plan 2015-2025 and later, a priority need to envision and develop a drilling operation that is less logistically intensive than the existing Foro 1650 Drill (formerly referred to as the Intermediate Depth Drill or IDD), to be used to retrieve ice cores from 700 m depth at alpine or polar ice coring sites with limited logistics and with two months or less time on site. In continuing discussions, it became evident that a smaller diameter core than the Foro drills produce (e.g., 98 mm) would result in significant logistical savings.

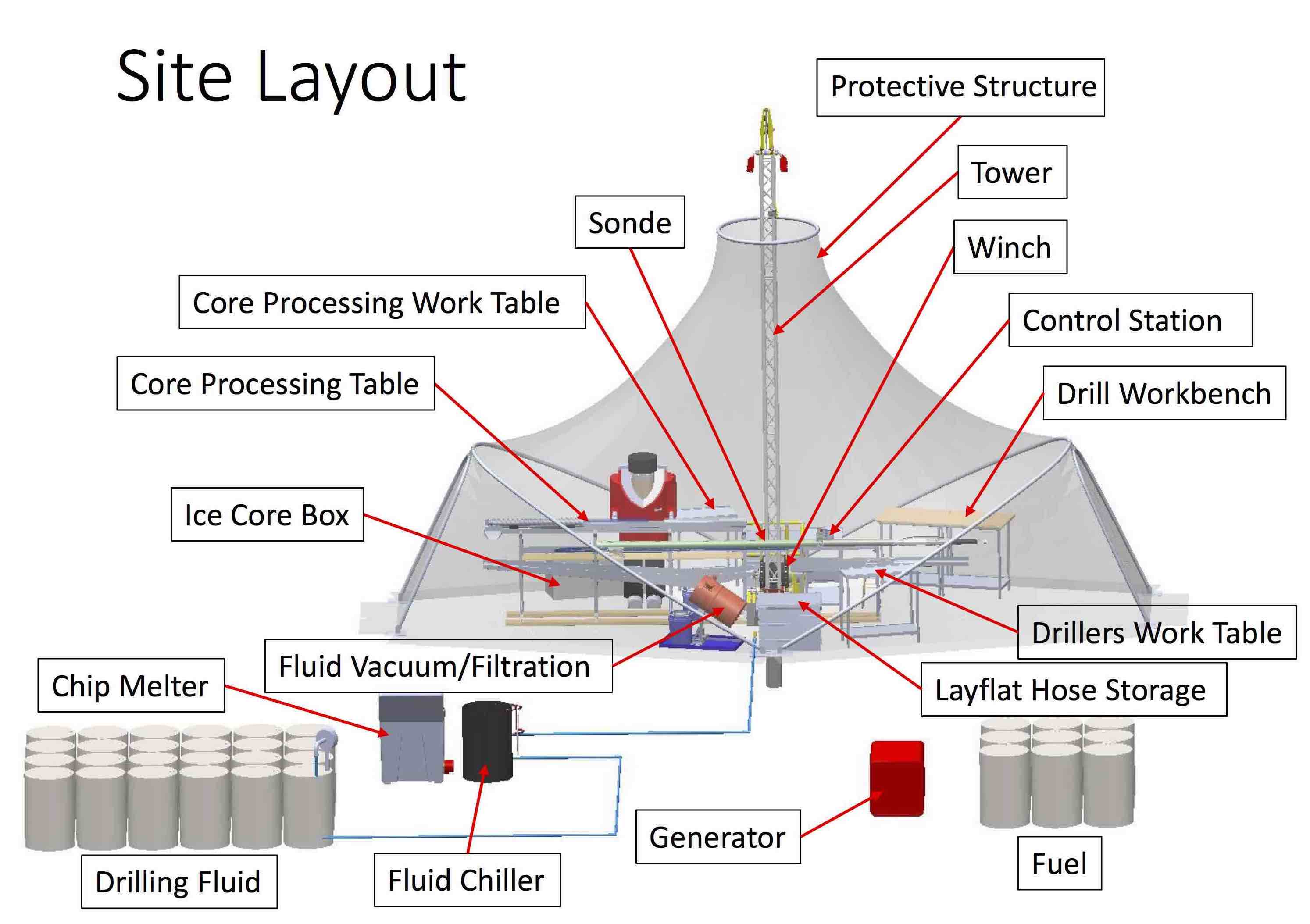

From discussions organized by IDP with iterative discussions between scientists, and IDP staff, the 700 Drill Science Requirements were finalized, a Conceptual Design was created, a Conceptual Design Review was completed, a Detailed Design was developed, and a Detailed Design Review was completed. The proposed 700 Drill system design is guided by and meets the science requirements identified by the research community. The system will be optimized to have minimal logistical requirements for drilling projects up to 700 meters in depth. The 700 Drill will produce a 70 mm diameter core (potentially adapting to 64 mm in the future) and 88 mm diameter borehole, which will minimize the quantity (i.e., volume and weight) of drilling fluid and the number and weight of core boxes. With NSF approval, IDP is now moving forward with the construction of the drill, currently slated for completion in February 2024.

IDP-WI Equipment Development and Maintenance Update

The third large compressor for IDP’s Rapid Air Movement (RAM) Drill received new plastic on its skis prior to shipment to Port Hueneme, CA, in mid-November. The compressor will travel on the resupply vessel to McMurdo Station, Antarctica, where it will be stored as a spare for the upcoming GHOST project (PI Anandakrishnan) on Thwaites Glacier.

Over the summer, the UW-Madison Space Science and Engineering Center (SSEC) secured additional space for IDP at the drill maintenance and warehouse facility. IDP’s electronics lab has been relocated to the new space, where the Foro 3000 and Foro 1650 Drill (previously referred to as the Intermediate Depth Drill or IDD) electronics are undergoing testing.

In preparation for the Detailed Design Review of the 700 Drill held on November 18, IDP engineers set up the Foro 400 Drill tent. The team believes a tent of very similar design could be used with the new drill slated to drill to 700 meters if fabrication is approved. A preliminary model of the 700 Drill subsystems can be seen below.

700 Drill Detailed Design Progress

Following NSF approval, IDP Engineers have now moved into the Detailed Design phase for the 700 Drill. The drill design is guided by and meets the science requirements identified by the research community. The small-diameter ice coring system will operate in a fluid-filled borehole to collect ice cores down to 700 m depth, all while minimizing logistics as much as possible. The 700 Drill will produce a 70 mm diameter core (potentially adapting to 64 mm in the future) and 88 mm diameter borehole, which will minimize the quantity (i.e., volume and weight) of drilling fluid and the number and weight of core boxes. IDP plans to hold an external design review with community scientists, ASC personnel, and the NSF in early PY 2022.

700 Drill

The IDP Science Advisory Board identified in the IDP Long Range Science Plan 2015-2025, and later, a priority need to alter the surface equipment for the existing Foro 1650 (Intermediate Depth Drill) to make a drilling operation that is less logistically intensive, to be used for alpine or polar ice coring at sites with limited logistics and with two months or less time on site. In continuing discussions, it became evident that a smaller diameter core would result in significant logistical savings. From discussions organized by IDP with iterative discussions between scientists, and IDP staff, the 700 Drill science requirements were finalized, and a Conceptual Design Review was also completed. The proposed 700 Drill system design is guided by and meets the science requirements identified by the research community. The system will be optimized to have minimal logistical requirements for drilling projects up to 700 meters depth. The proposed 700 Drill system will produce the smallest core diameter (70 mm initially, potentially adapting to 64 mm in the future) and borehole diameter (88 mm) of the IDP suite of drills, which will minimize the quantity (i.e., volume and weight) of drilling fluid and the number and weight of core boxes. Pending NSF approval, IDP will move forward with the Detailed Design phase for the 700 Drill and, when completed, will present the design to community scientists and NSF for review.

Equipment Development (2016 Fall)

Agile Sub-Ice Geological Drill

During the fourth quarter, IDDO completed all of the system modifications, repairs and upgrades identified during testing performed in the second quarter. The system was shipped to Port Hueneme, CA, in mid-September for use this coming Antarctic field season on PI John Stone's project (see Field Support to Antarctic Projects above).

Winkie Drill

During the quarter, IDDO completed the fabrication, assembly, and modifications of the Winkie Drill. On 9/16/16, the Winkie Drill system was shipped to Port Hueneme, CA, for its first Antarctic deployment on PI Mukhopadhyay's project (see Field Support to Antarctic Projects above).

Rapid Air Movement (RAM) Drill

During the quarter, IDDO continued review of the existing sled design and its suitability for use with a reverse circulation dual walled pipe drill. With interest by both the seismic and physics communities on modification and use of the RAM Drill, IDDO plans to work with IDPO in PY 2017 (Nov 1, 2016 - October 31, 2017) to develop updated science requirements for the drill, upon which all subsequent modifications and upgrades will be based. During the quarter, IDDO also completed necessary paperwork for participation in a capstone project at the Colorado School of Mines (CSM). The project was accepted for the current school year where CSM students will study air flow and down hole tooling analysis for the RAM Drill.

MAgIC Drill/Intermediate Depth Drill-Light

Throughout PY 2016, IDDO worked with IDPO and community scientists to develop and refine science requirements for a drill similar to the 1500 m Intermediate Depth Drill, but with a depth target between 400-700 meters and with a much-reduced logistics burden to allow for coring on remote glaciers, for instance, in Alaska. IDDO is working with IDPO and interested community scientists to develop an approach to the desired equipment, and is in the process of compiling system options to present to the community. A decision on the naming of the new system, and whether or not it will be built, will be determined once the science requirements are finalized.

Foro Drill

IDDO continued to procure drill components for the Foro Drill during the quarter as planned, including a slip ring and a winch frame assembly. Design of the cable was finalized and the cable subsequently ordered in early August. The control box layout was reviewed, the mechanical design of the box was finalized, and custom aluminum cases and faceplates were procured.

Deep Ice Sheet Coring (DISC) Drill

Any further development work for the DISC Drill remains on hold, until the science community identifies if/when the system will next be deployed.

Equipment Development (2016 Summer)

Agile Sub-Ice Geological Drill

During the third quarter, IDDO worked to complete system modifications, repairs and upgrades identified during testing performed in the second quarter. The Agile Sub-Ice Geological Drill is expected to ship to Antarctica in September. Validation and verification are now underway and documentation will be completed in the fourth quarter.

Winkie Drill

During the third quarter, IDDO completed an internal system design review as well as all necessary fabrication, assembly, and modifications of the Winkie Drill. Multi-round system testing was completed, including ice drilling with a newly-designed air chip transport system and modified Forstner and Irwin bits, coring through an ice/rock interface with multiple layers of ice and different sizes of granite rocks using two different types of mixed-media coring bits and a range of Isopar K temperatures, and coring solid granite with three different types of coring bits and two types of drilling fluid (Isopar K and water). System testing was very successful and helped inform selection of drilling/coring bits for a variety of ice/rock conditions the drill may encounter in the field. In conjunction with system testing, IDDO completed two days of operational training, conducted by Earl Maynard, a Winkie Drill expert, in Madison in July 2016. IDDO continued minor system modifications and started final procurement of replacement and spare parts.

Rapid Air Movement (RAM) Drill

During the quarter, IDDO continued researching multiple approaches for RAM Drill modification and decided to primarily focus on a dual walled pipe drill design that looks more promising than a dual walled hose design or a design based on a new standard hose reel assembly. IDDO started reviewing the existing sled design and its suitability for use with a reverse circulation dual walled pipe drill.

MAgIC Drill/Intermediate Depth Drill-Light

During the quarter, IDDO continued working with IDPO and community scientists to refine science requirements for a drill based on the 1,500 m Intermediate Depth Drill (IDD), but with a depth target between 400-700 m and with a much-reduced logistics burden to allow for coring on remote glaciers. IDDO sent the next round of comments/edits of the IDPO Science Requirements to IDPO on 6/20/16. A decision on the naming of the new system, and whether or not it will be built, is ongoing.

Foro Drill

IDDO procured several major Foro Drill components during the quarter as planned, including a Lebus core for the winch drum, a winch motor, a winch motor gearbox, a motor VFD and a pre-fabricated cable assembly for the winch control loop. IDDO finalized the design and ordered a new four-conductor cable in early August. All components for testing of the winch control loop were received. IDDO completed a dimensional report on the winch Lebus core. This core was sent to Innovative Machine Specialists for final assembly, including heat treatment, anodizing and machining. The control box layout was reviewed, and IDDO began finalizing the mechanical design of the box.

Deep Ice Sheet Coring (DISC) Drill

Any further development work for the DISC Drill remains on hold, until the science community identifies if/when the system will next be deployed.

Equipment Development (2016 Spring)

Agile Sub-Ice Geological Drill

During the Second Quarter, IDDO initiated full-scale system testing of the Agile Sub-Ice Geological (ASIG) Drill outside of Madison, Wisconsin on the UW Physical Sciences Lab (PSL) campus. IDDO engineers, a contract driller and a trainer from the rig vendor, Multi-Power Products, LLC, were able to test a variety of operations, per the Test Plan drafted by IDDO Project Manager Chris Gibson, including the coring of ice, concrete, solid granite and mixed media. The team was also able to tune the rig, refine fuel and drilling fluid consumption rates, determine the expected operational parameters of the system, such as penetration rates, and identify and refine the spare parts list. The rig performed reliably and is expected to meet or surpass all related science requirements. IDDO hosted several visitors to the test site on February 26, 2016, including Bill Eustes, Blaise Stephanus and Mark Twickler from IDPO, as well as PI John Stone, as the drill system will be used first for his upcoming project in 2016-2017 near Pirrit Hills in Antarctica. Leah Street from ASC, in Madison on other business, was also able to visit the site, as well as several other IDDO personnel. Late in the quarter, IDDO engineers quickly transitioned to system modifications, repairs and upgrades, in anticipation of shipping the system to Antarctica in September.

Winkie Drill

During the Second Quarter, IDDO continued its modifications and upgrades to the off-the-shelf Winkie Drill purchased from Minex. Early in the quarter, IDDO was able to test its adaptations of auger flights during the Rapid Access Ice Drill (RAID) Auger and Packer Test near McMurdo Station. Important information was gained regarding penetration rates, expected fuel consumption, and the augers' ability to transport ice chips to the surface. Taking advantage of the ASIG Drill test set up, the transportation of ice chips by air was tested as a proof of concept for drilling options in the deep field. Later in the quarter, IDDO identified two types of mixed media coring bits, completed fabrication of a rig base for the system to support the drill and evenly distribute loads across the snow surface during core breaks, completed installation and testing of a variable frequency motor drive for the mud pump, and completed modifications of a drill fluid filtration drum. IDDO will continue its work into the Third Quarter, and also plans to complete additional testing and training in Madison in July 2016, prior to shipping the system to Antarctica in September.

Rapid Air Movement Drill

During the quarter, IDDO began researching a new hose reel design for the Rapid Air Movement (RAM) Drill. IDDO also explored dual-wall hose designs and rigid, lightweight aluminum pipe applications as it looks to lighten and lessen the drill's logistics for future deployments. IDDO engineers also corresponded with engineers in the Chinese drilling program, as they are investigating similar technologies.

MAgIC Drill/Intermediate Depth Drill-Light

During the quarter, IDDO worked with IDPO and community scientists to develop and refine science requirements for a drill similar to the 1,500 meter Intermediate Depth Drill (IDD), but with a depth target between 500-900 meters and with a much-reduced logistics burden to allow for coring on remote glaciers, for instance, in Alaska. A decision on the naming of the new system, and whether or not it will be built, should be resolved in the Third or Fourth Quarters.

Foro Drill

IDDO ramped up its design of the Foro Drill during the quarter, corresponding with winch drum and other winch component manufacturers. IDDO initiated procurement of components for prototyping the winch control system and building the new Foro control box.

Deep Ice Sheet Coring Drill

IDDO has temporarily put any further development work for the Deep Ice Sheet Coring (DISC) Drill on hold, until the science community identifies if/when the system will next be deployed. Some minor maintenance and cleaning up of the LabVIEW software was completed during the quarter. A good portion of the DISC Drill cargo also returned from Antarctica in April, and is being unpacked and dried.

Equipment Development (2013 Winter)

Deep Logging Winch

In the first quarter of PY 2014 (Nov-Jan), IDDO completed the building and testing of a new Deep Logging Winch, capable of reaching the depth of 4,000 meters. At the end of the quarter, the logging winch system required only the completion of the shipping container for the logging tower to be ready for shipment to the field.

Intermediate Depth Drill

IDDO is in the final stage of the development of a new Intermediate Depth Drill, capable of producing ice cores to depths of 1,500 meters. In the first quarter of PY 2014, the procurement of all system parts and components was nearly completed. At the same time, most major assemblies, including the tower, the winch, and the sonde were completed and partially tested as well. Completion of several of the electronics modules, however, has lagged as the result of the responsibility for remaining design, fabrication and testing being assumed by contract engineers and a contract technician after the resignation of the IDDO staff electrical engineer last fall. After the completion of the system integration test in Madison in March of 2014, the entire system will be ready for a full field test in Greenland during the spring-summer of this year.

Blue Ice Drill-Deep

The Blue Ice Drill-Deep is a new drill based on the original Blue Ice Drill (BID) with the capability of reaching depths of 200 meters. The design and procurement of all drill parts and components were completed in the first quarter; all major assembly of new subsystems was completed as well. Modifications and repairs to the base BID, the final assembly of the BID-Deep Drill, and the lab testing will be completed after IDDO receives the base BID back from Antarctica. The BID-Deep system will be shipped to Greenland for testing and fieldwork this summer.

Scalable Hot Water Access Drill

In response to community need for a scalable modular hot water access drill in the Long Range Science Plan, IDDO has started work on a modular hot water drill for the community. This drill will be useful for investigating sub-ice shelf mass balance, ice-ocean interactions, grounding zone processes, and other studies. Mary Albert worked with science community representatives Sarah Das, Dave Holland, and Ted Scambos, and with Chris Gibson, IDDO project manager and engineer and Terry Benson, a University of Wisconsin Engineer with hot water drill experience, through an iterative process to define the science requirements for a hot water drill whose size could be scaled to project needs. The Science Requirements for the Scalable Hot Water Access Drill are available at http://icedrill.org/documents/view.shtml?id=1192. Questions or comments should be sent to Mary Albert.

Agile Sub-Ice Geological Drill

One of the goals for development of new drills identified in the IDPO Long Range Science Plan is the need for agile methods for reconnaissance recovery of small rock cores near ice margins. In response to this, IDPO-IDDO has initiated work on a new Agile Sub-Ice Geological Drill capable of coring up to 10 meters of rock core beneath hundreds of meters of ice. The Science Requirements for this drill were developed in an iterative process led by Mary Albert with community representatives John Stone, Jaakko Putkonen, and Ed Brook, and with IDDO engineer Tanner Kuhl. The Science Requirements are available at https://icedrill.org/equipment/agile-sub-ice-geological-drill. IDPO-IDDO is currently investigating partnership with a small minerals exploration drill manufacturer for development of this drill. The first use of this drill is planned for Antarctic field season 2015-2016 for recovery of rock pieces under several hundred meters of ice. Questions or comments should be sent to Mary Albert.

Agile Ice Coring Drill

In response to the need for an ice coring drill for depths between approximately 400-900 m and that is also agile for use in mountain glaciers and areas with limited logistics, IDPO will be working with community members and with IDDO engineers to develop Science Requirements for the drill. Any U.S. community scientist interested in participating in iterative discussions to identify the requirements should contact Mary Albert at Icedrill@dartmouth.edu.