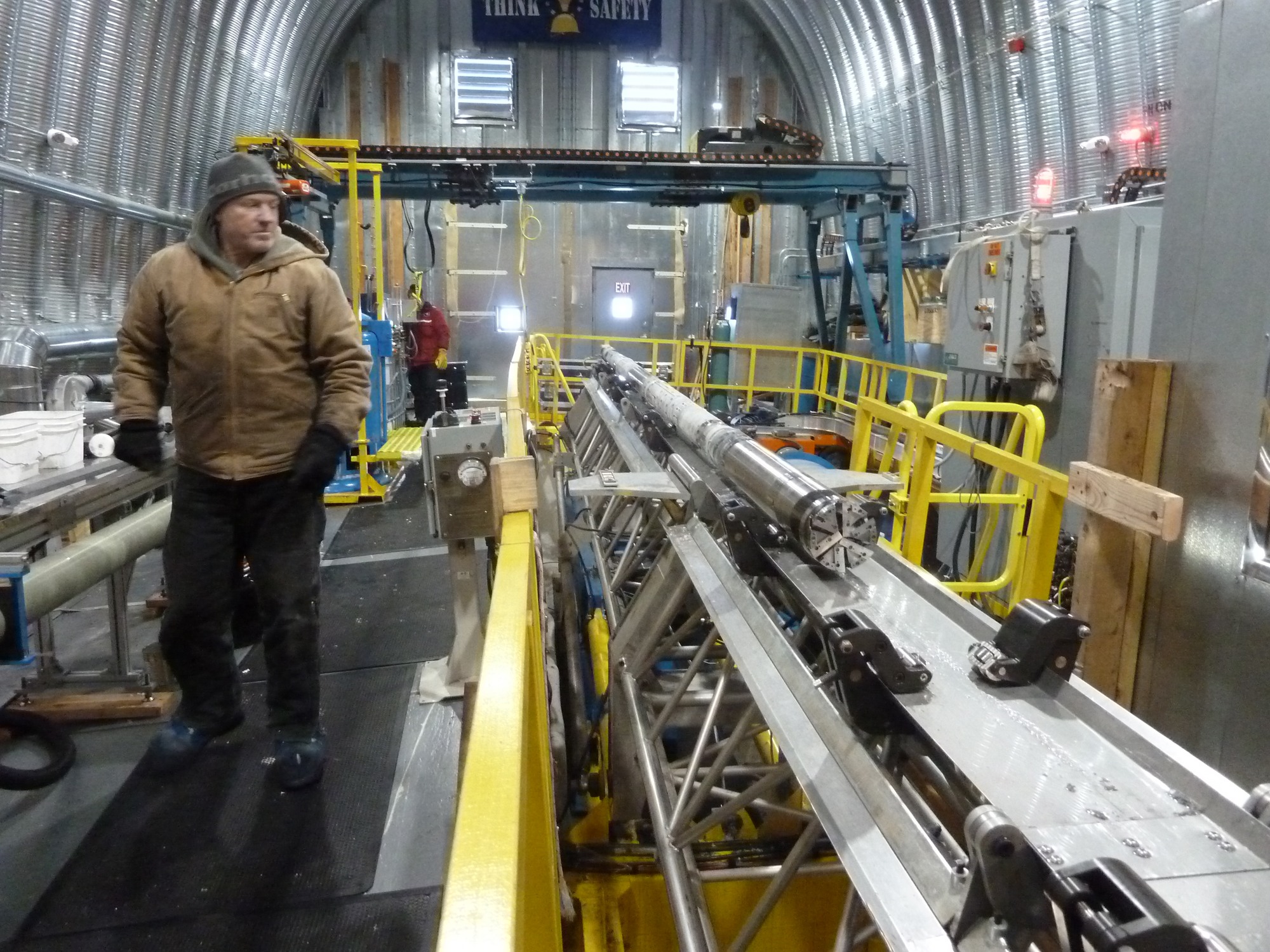

Agile Sub-Ice Geological Drill

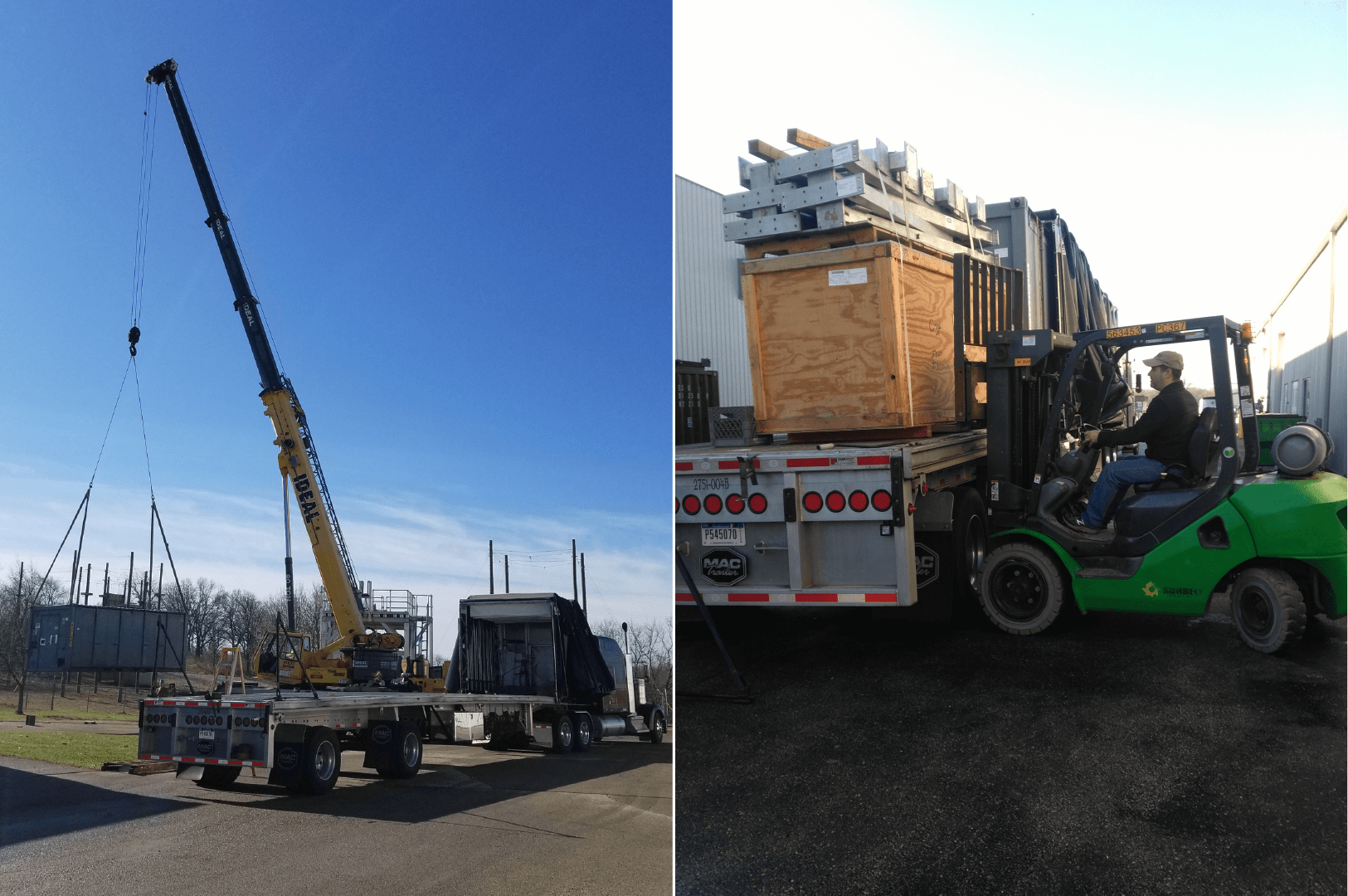

During the Second Quarter, IDDO initiated full-scale system testing of the Agile Sub-Ice Geological (ASIG) Drill outside of Madison, Wisconsin on the UW Physical Sciences Lab (PSL) campus. IDDO engineers, a contract driller and a trainer from the rig vendor, Multi-Power Products, LLC, were able to test a variety of operations, per the Test Plan drafted by IDDO Project Manager Chris Gibson, including the coring of ice, concrete, solid granite and mixed media. The team was also able to tune the rig, refine fuel and drilling fluid consumption rates, determine the expected operational parameters of the system, such as penetration rates, and identify and refine the spare parts list. The rig performed reliably and is expected to meet or surpass all related science requirements. IDDO hosted several visitors to the test site on February 26, 2016, including Bill Eustes, Blaise Stephanus and Mark Twickler from IDPO, as well as PI John Stone, as the drill system will be used first for his upcoming project in 2016-2017 near Pirrit Hills in Antarctica. Leah Street from ASC, in Madison on other business, was also able to visit the site, as well as several other IDDO personnel. Late in the quarter, IDDO engineers quickly transitioned to system modifications, repairs and upgrades, in anticipation of shipping the system to Antarctica in September.

Winkie Drill

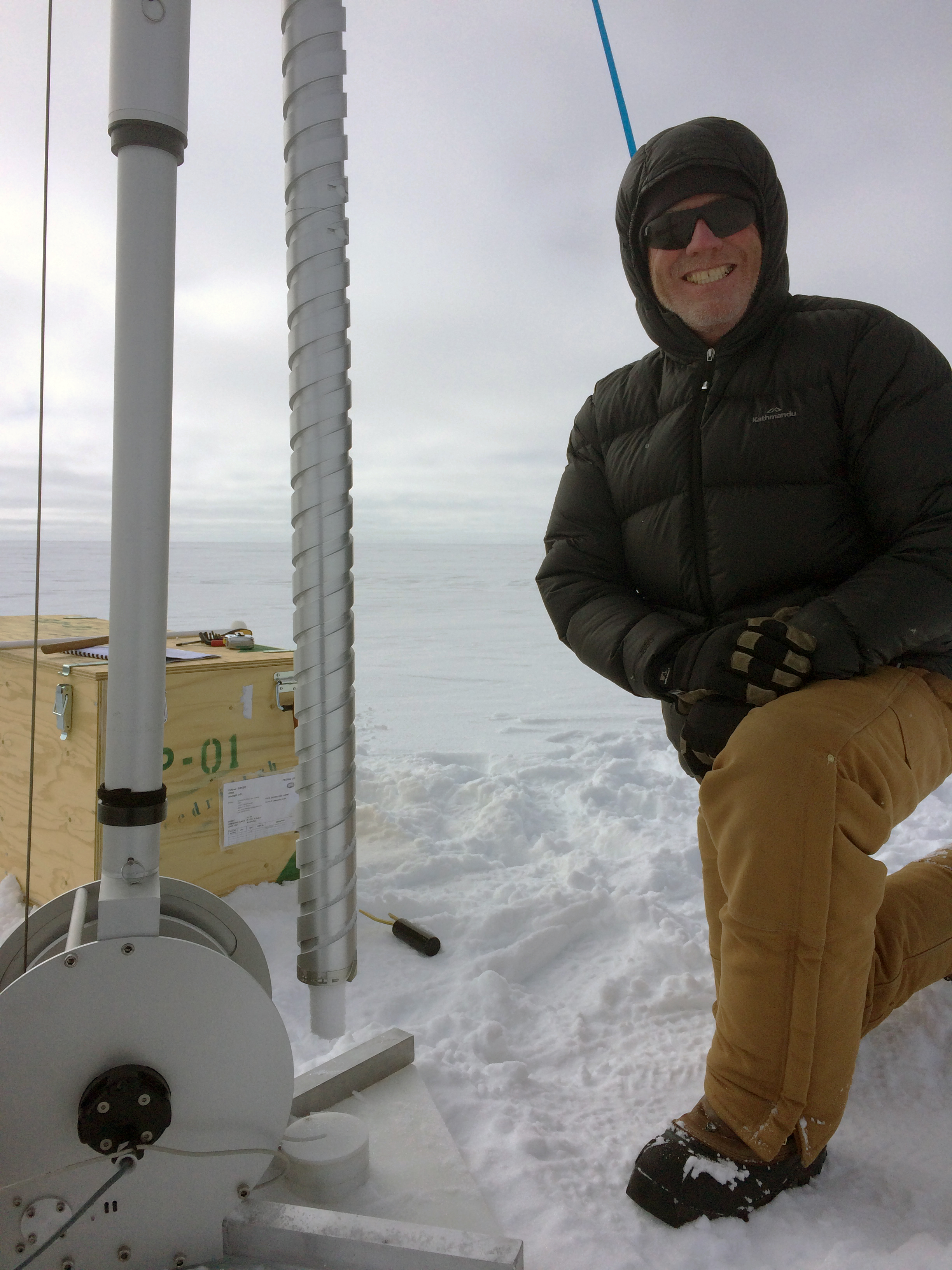

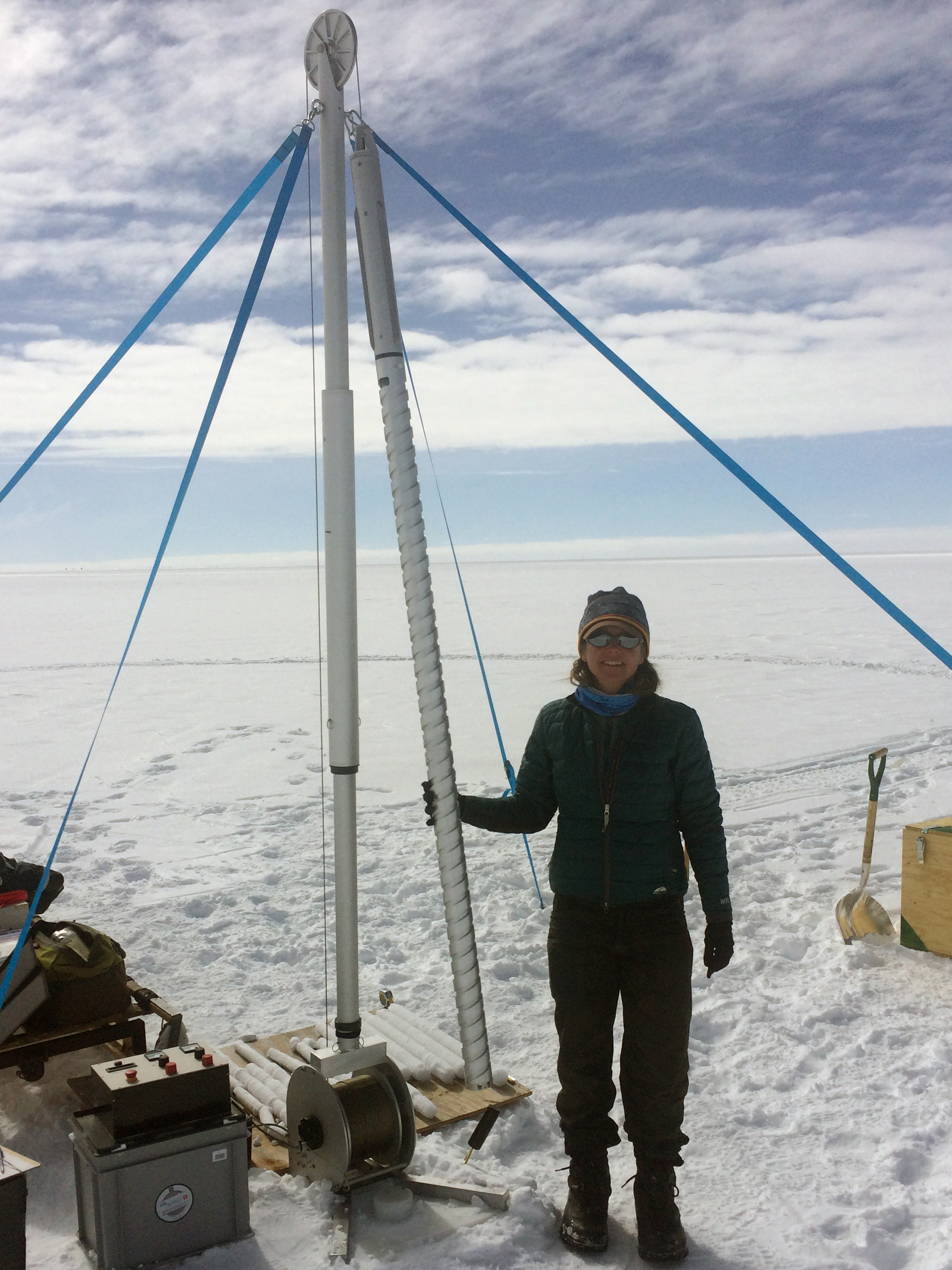

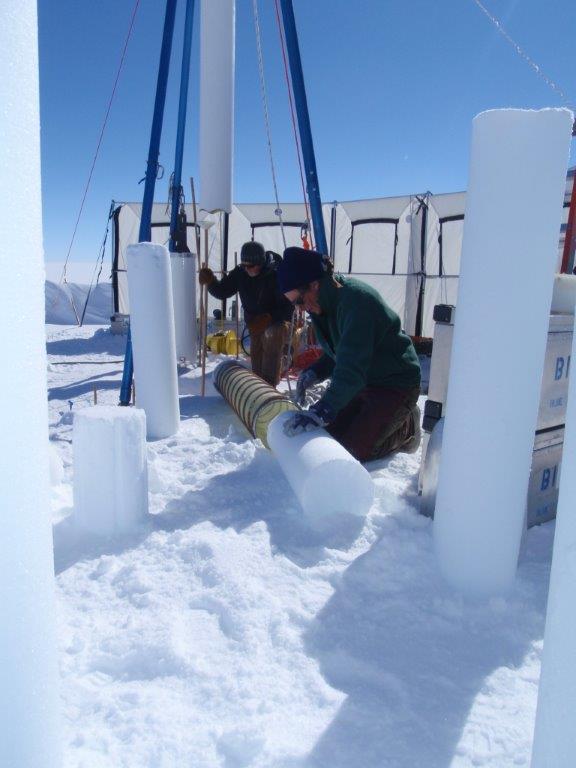

During the Second Quarter, IDDO continued its modifications and upgrades to the off-the-shelf Winkie Drill purchased from Minex. Early in the quarter, IDDO was able to test its adaptations of auger flights during the Rapid Access Ice Drill (RAID) Auger and Packer Test near McMurdo Station. Important information was gained regarding penetration rates, expected fuel consumption, and the augers' ability to transport ice chips to the surface. Taking advantage of the ASIG Drill test set up, the transportation of ice chips by air was tested as a proof of concept for drilling options in the deep field. Later in the quarter, IDDO identified two types of mixed media coring bits, completed fabrication of a rig base for the system to support the drill and evenly distribute loads across the snow surface during core breaks, completed installation and testing of a variable frequency motor drive for the mud pump, and completed modifications of a drill fluid filtration drum. IDDO will continue its work into the Third Quarter, and also plans to complete additional testing and training in Madison in July 2016, prior to shipping the system to Antarctica in September.

Rapid Air Movement Drill

During the quarter, IDDO began researching a new hose reel design for the Rapid Air Movement (RAM) Drill. IDDO also explored dual-wall hose designs and rigid, lightweight aluminum pipe applications as it looks to lighten and lessen the drill's logistics for future deployments. IDDO engineers also corresponded with engineers in the Chinese drilling program, as they are investigating similar technologies.

MAgIC Drill/Intermediate Depth Drill-Light

During the quarter, IDDO worked with IDPO and community scientists to develop and refine science requirements for a drill similar to the 1,500 meter Intermediate Depth Drill (IDD), but with a depth target between 500-900 meters and with a much-reduced logistics burden to allow for coring on remote glaciers, for instance, in Alaska. A decision on the naming of the new system, and whether or not it will be built, should be resolved in the Third or Fourth Quarters.

Foro Drill

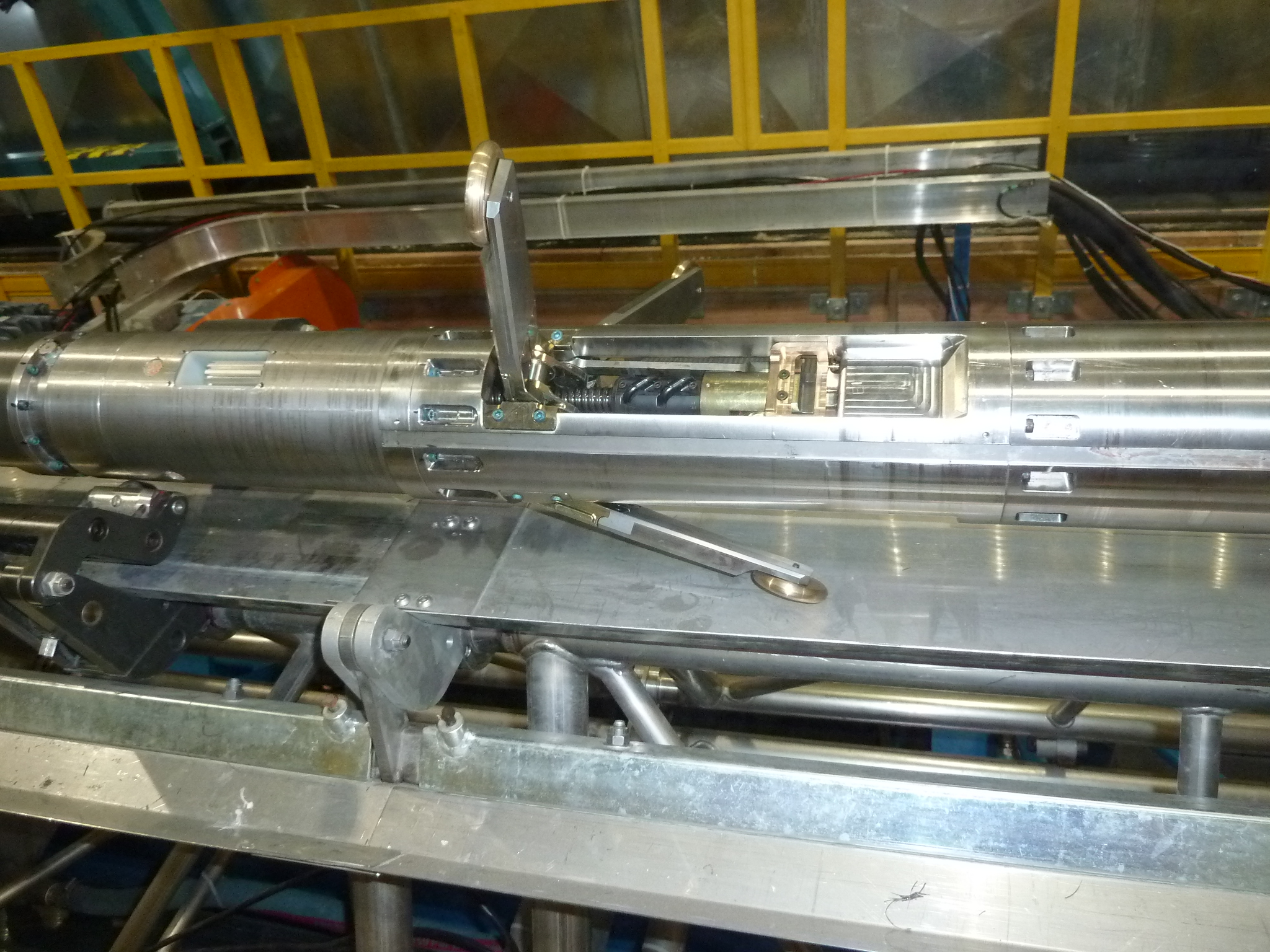

IDDO ramped up its design of the Foro Drill during the quarter, corresponding with winch drum and other winch component manufacturers. IDDO initiated procurement of components for prototyping the winch control system and building the new Foro control box.

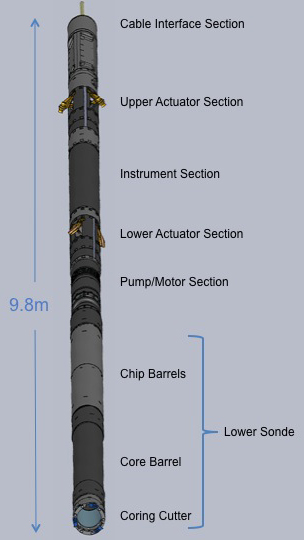

Deep Ice Sheet Coring Drill

IDDO has temporarily put any further development work for the Deep Ice Sheet Coring (DISC) Drill on hold, until the science community identifies if/when the system will next be deployed. Some minor maintenance and cleaning up of the LabVIEW software was completed during the quarter. A good portion of the DISC Drill cargo also returned from Antarctica in April, and is being unpacked and dried.