Foro 3000 Drill

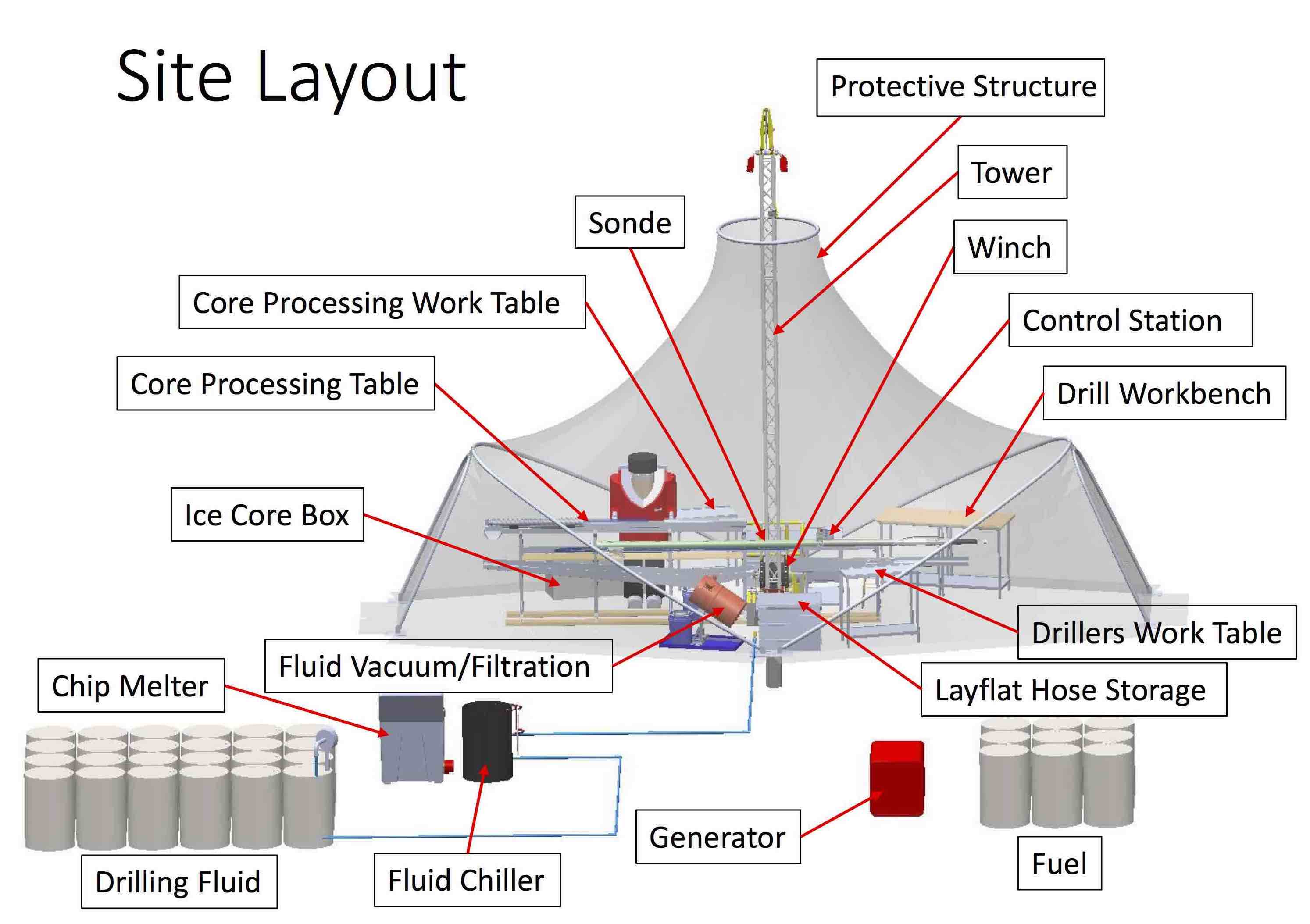

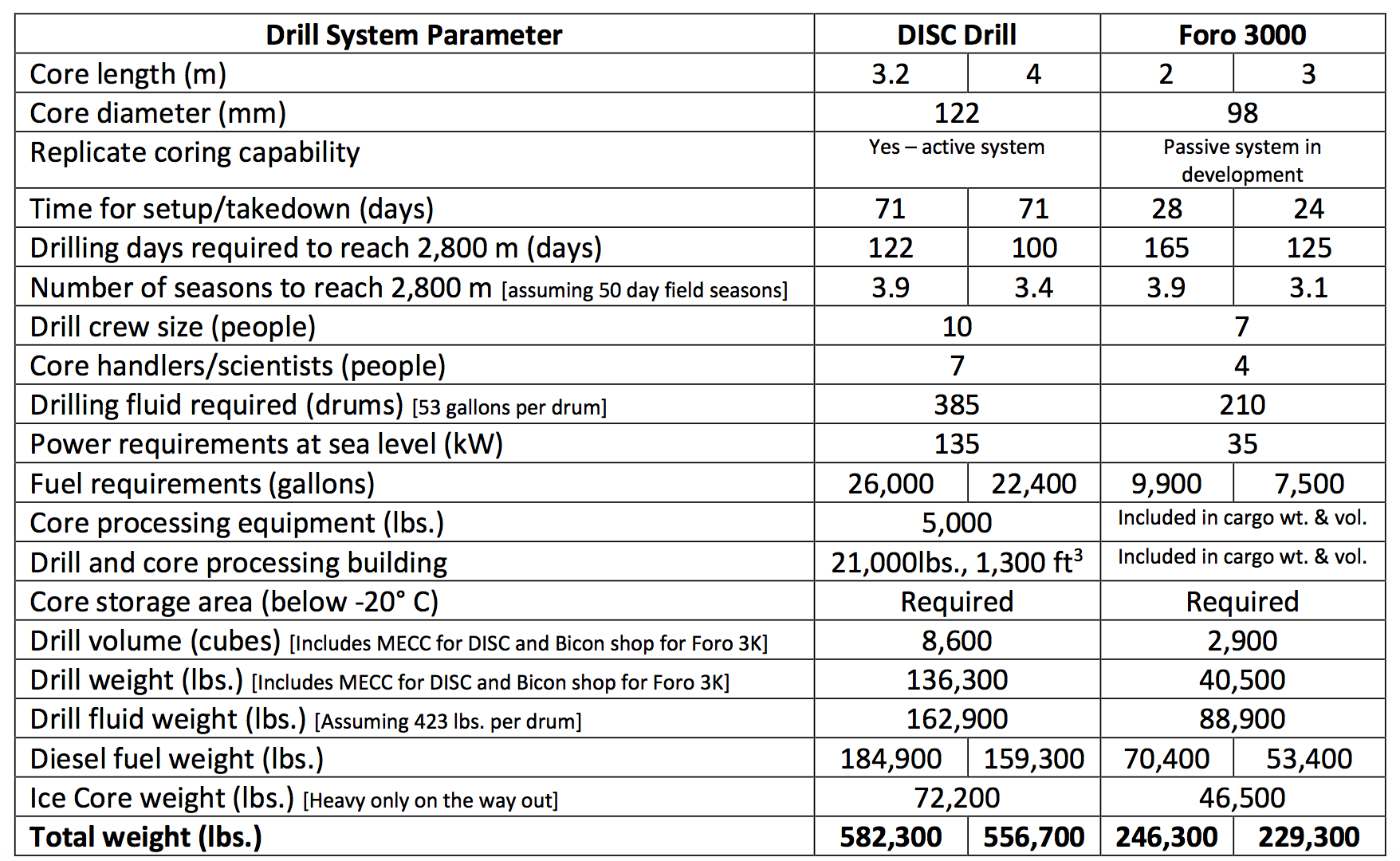

IDDO continued initial development tasks for the Foro 3000 Drill system during the third quarter. Detailed design of the winch drum and level wind are in process. Sizing calculations were made and a design initiated for the chip melter system. Sonde assembly drawings were largely completed. Design work is expected to ramp up in the fourth quarter in preparation for a Detailed Design Review in late September.

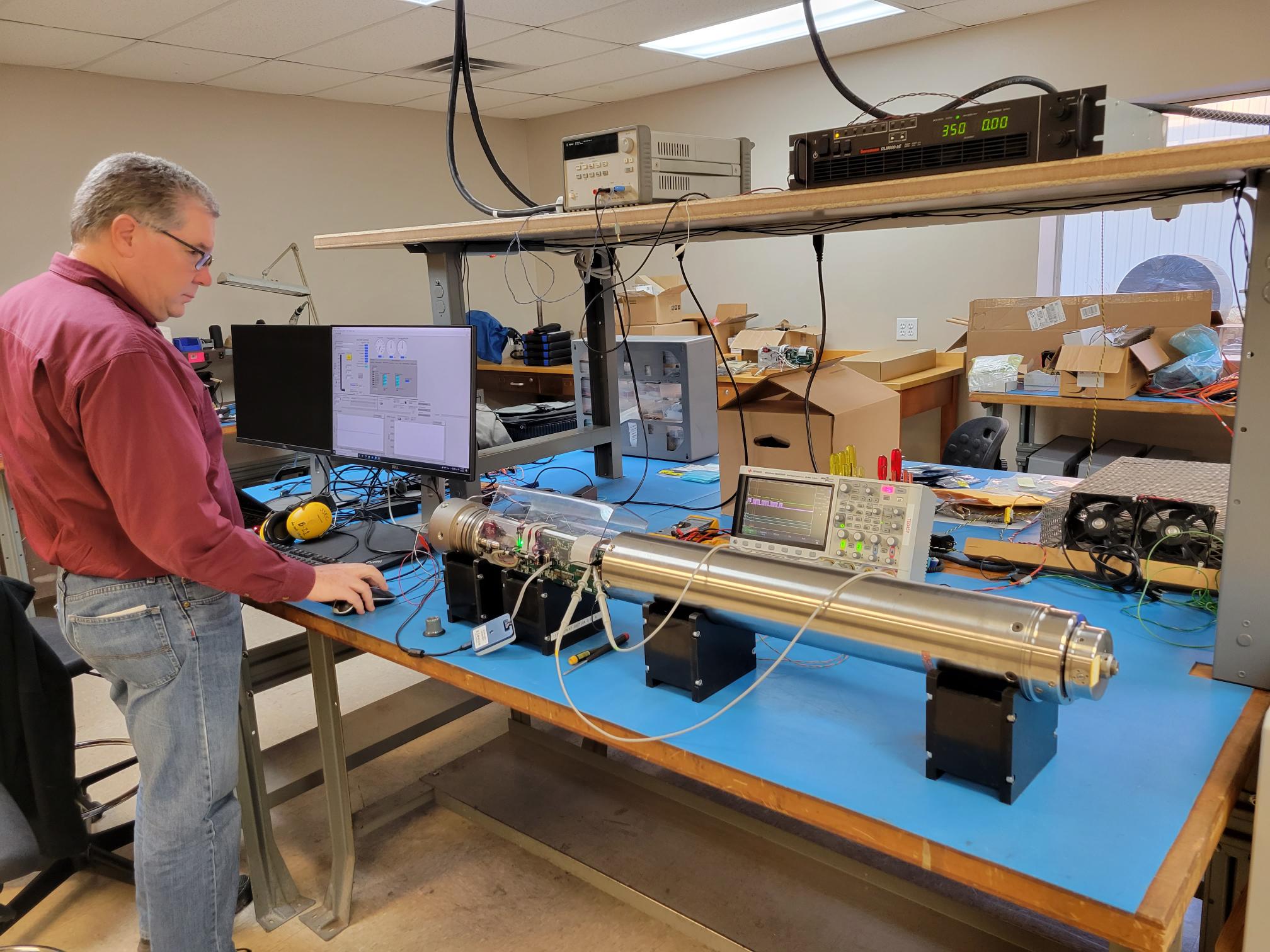

Foro Drill

Anti-torque section assembly was largely completed and motor section assembly was initiated on the Foro Drill. Cabling was completed for the control box and drill motors were ordered. Shipping cases were received for the sonde, tower, and winch. Cutter head assemblies, spare cable terminations, and anti-torque slip rings were also received. Some assembly and testing have been delayed in light of work on higher priority projects, but procurements are largely complete.

Rapid Air Movement (RAM) Drill

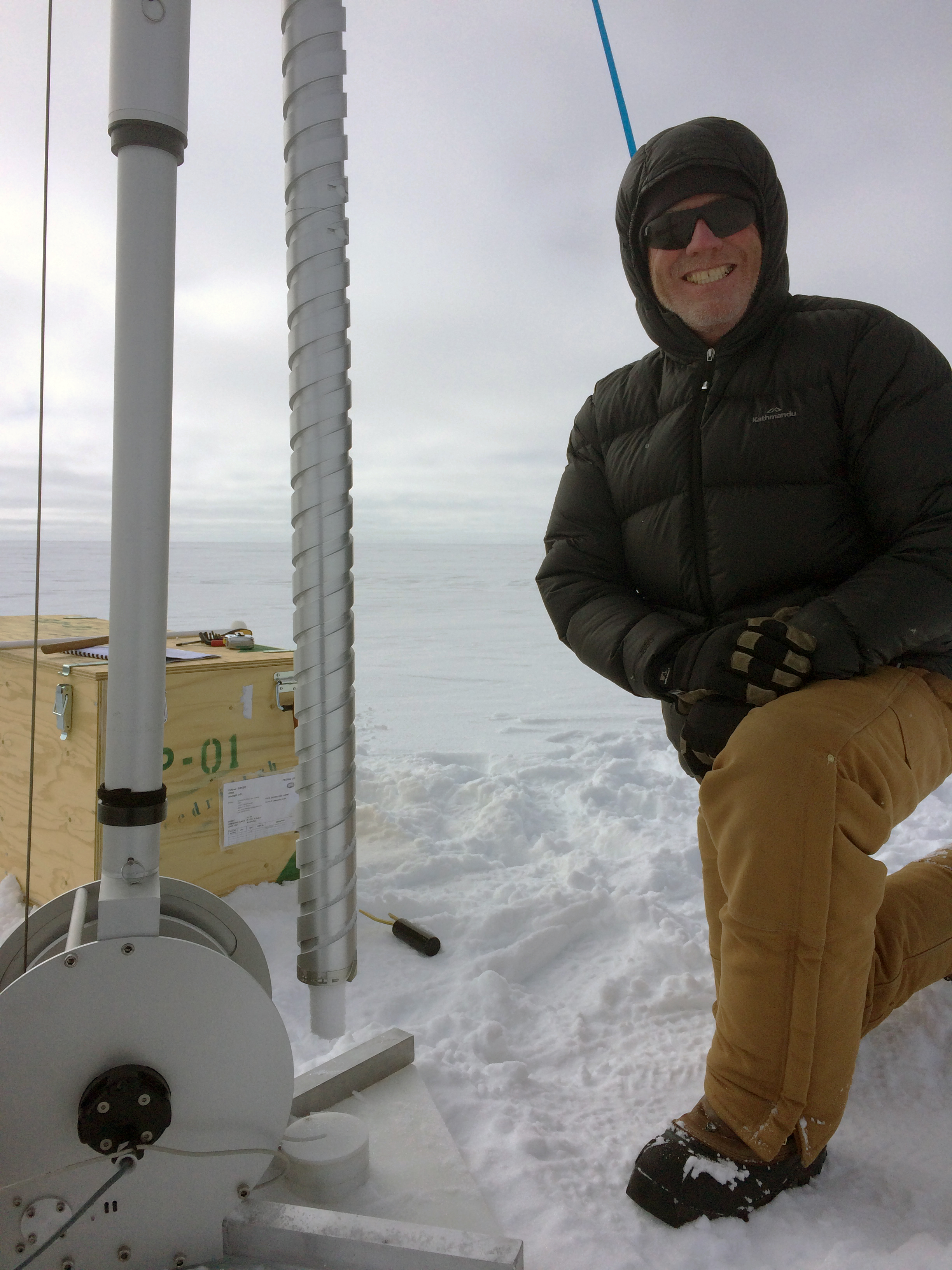

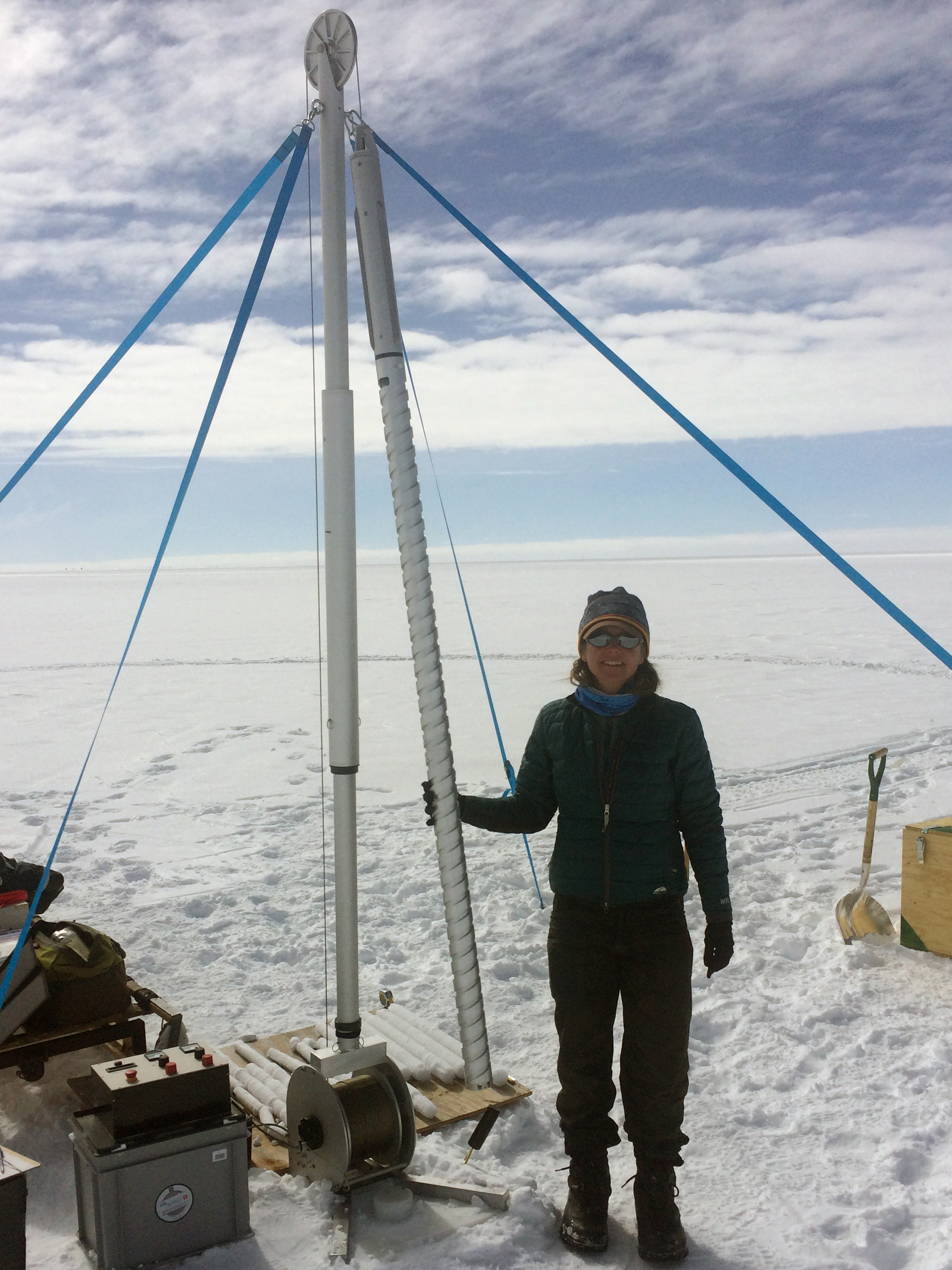

Continued acceleration of RAM Drill design, procurement, and in-house testing. The system was prepared, packed and shipped to Scotia, NY in late June. In early July, IDDO received an Expedition Permit from the Government of Greenland, and a two-week field test was subsequently completed at Camp Raven in late July.

Intermediate Depth Drill

Models and drawings were completed for the winch cable terminations and spare cable termination kits were received for the Intermediate Depth Drill. System maintenance continues at a slow pace, as does the testing and troubleshooting of the Mage Controls components. The components, returned to Mage Controls at the end of the second quarter, are expected back at IDDO early in the fourth quarter.

Winkie Drill

Borehole casing was specified and purchased in preparation for the Winkie Drill's first use in West Antarctica at a drill site with overlying firn. IDDO sought information from international colleagues regarding methods to seal the bottom of the casing to the ice. Packer components, benchtop testing for compressed air inflation, and detailed models of packer components were also researched.

Blue Ice Drill (BID)

Maintenance and upgrade tasks were largely completed during the quarter for the BID-1. The drill was subsequently cleaned, packed and shipped for the upcoming Law Dome project in Antarctica. IDDO continued communication with BID tent vendor Fabricon. Engineer Tanner Kuhl visited the vendor's location in mid-July to review the design and progress thus far, and the tent was completed in mid-August.

Thermal Drill

The Engineering Requirements document for the Thermal Drill was approved and released. IDDO engineers worked to identify, procure and test some thermal and power limiting materials and components during the quarter. New heat rings were specified, as the old model is now out of production, and a number of new rings were ordered late in the quarter.

Hand Augers

Planned modifications for the cleat and locking break components of the SideWinder units were implemented on all five kits in inventory. Equipment was returned from Svalbard and Greenland and was repaired as needed. Orders were subsequently placed for replacement of a few components that were stuck in the ice during the 2018 Arctic fieldwork.

4-Inch Drills

Maintenance was completed for the 4-Inch Drill system that returned from Antarctica. One core barrel set was modified to match beneficial modifications made to another barrel set in inventory. An improved cable keeper for the crown sheave was designed, fabricated and implemented.

Eclipse Drills

A more robust top cover and new side panels were installed on the Eclipse Drill traversing system. Beneficial updates were made to the Operator's Manual. Small tools such as strap wrenches and sharpening stones were purchased for use in the field.