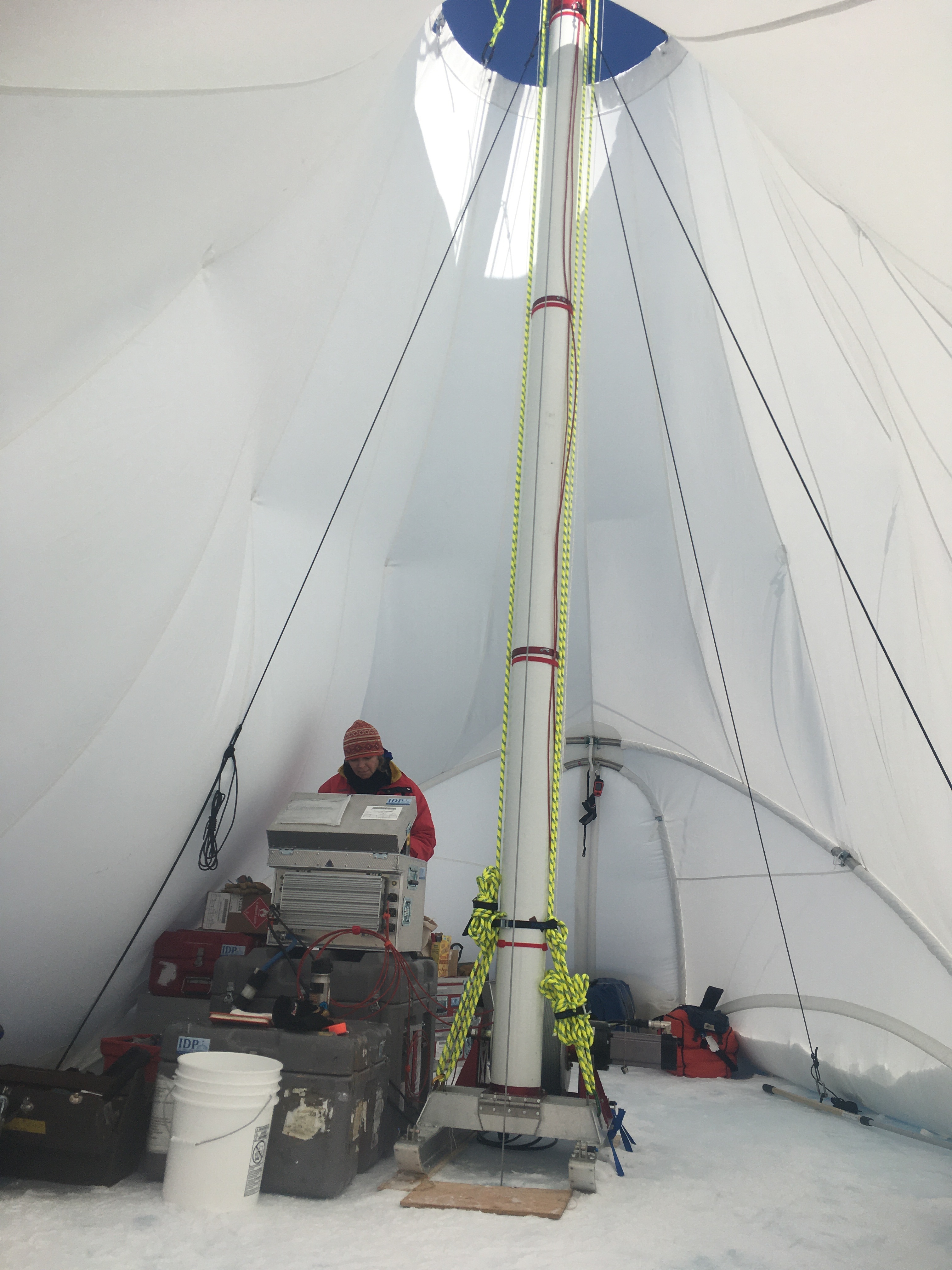

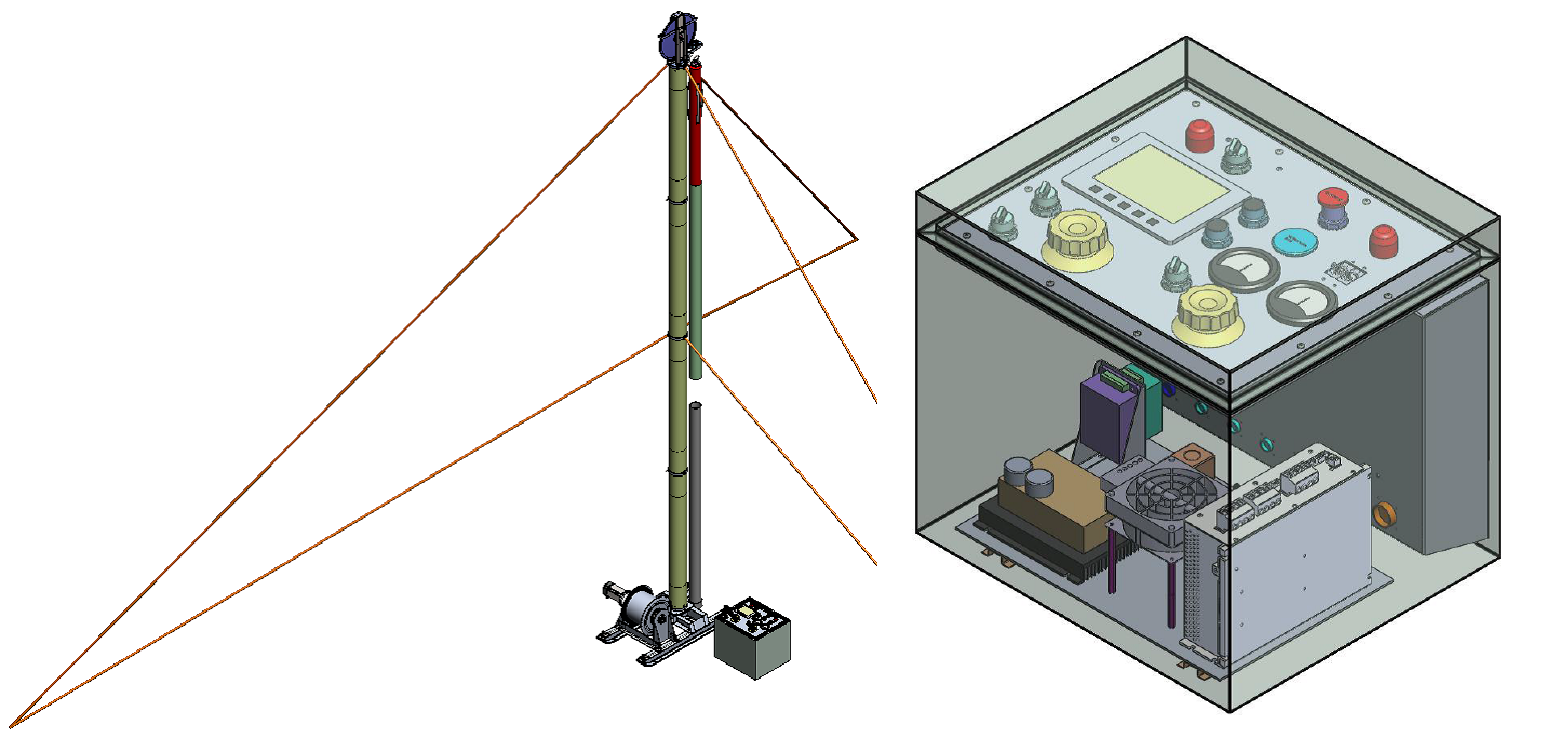

Development of the 700 Drill continued at an excellent pace. The control box and console wiring were completed, and the control box was powered up and tested. The design of the chip bailer continued, and sonde components like the outer tube, hollow shaft, and core barrel were fit-checked. IDP met with personnel at the UW Physical Sciences Lab (PSL) to coordinate the testing of subsystems in the PSL test well. Work continued on the sonde electronics. The motor torque test stand was assembled, and engineers immediately began gathering and analyzing data. Orders were placed for core processing and fluid handling system components. The drill cable was successfully spooled onto the winch. The first use of the 700 Drill is scheduled for the summer of 2024 in support of PI Eric Saltzman’s molecular hydrogen (H2) project (NSF award 2243540) at Summit, Greenland.

The Engineering Requirements document for the BASE (Basal Access and Subglacial Exploration) Drill system was finalized and approved. Drill rod was ordered and received. Jay Johnson and Elliot Moravec traveled to Multi-Power Products Ltd in Kelowna, BC, in February for drill acceptance and operational training. IDP expects to receive the drill in Madison, WI, in March or April, and will work to design the auxiliary components for use of the drill in ice in the polar regions.

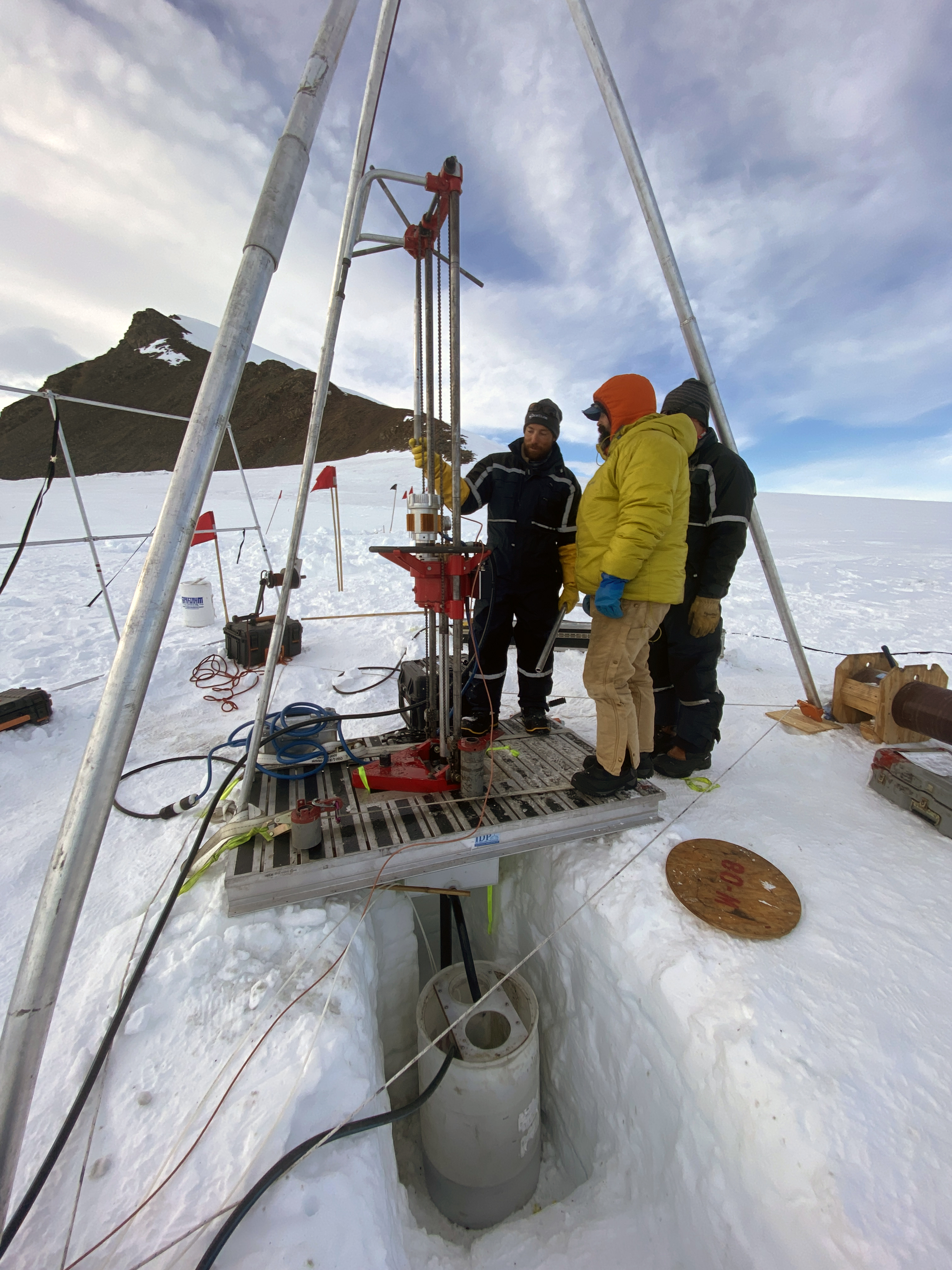

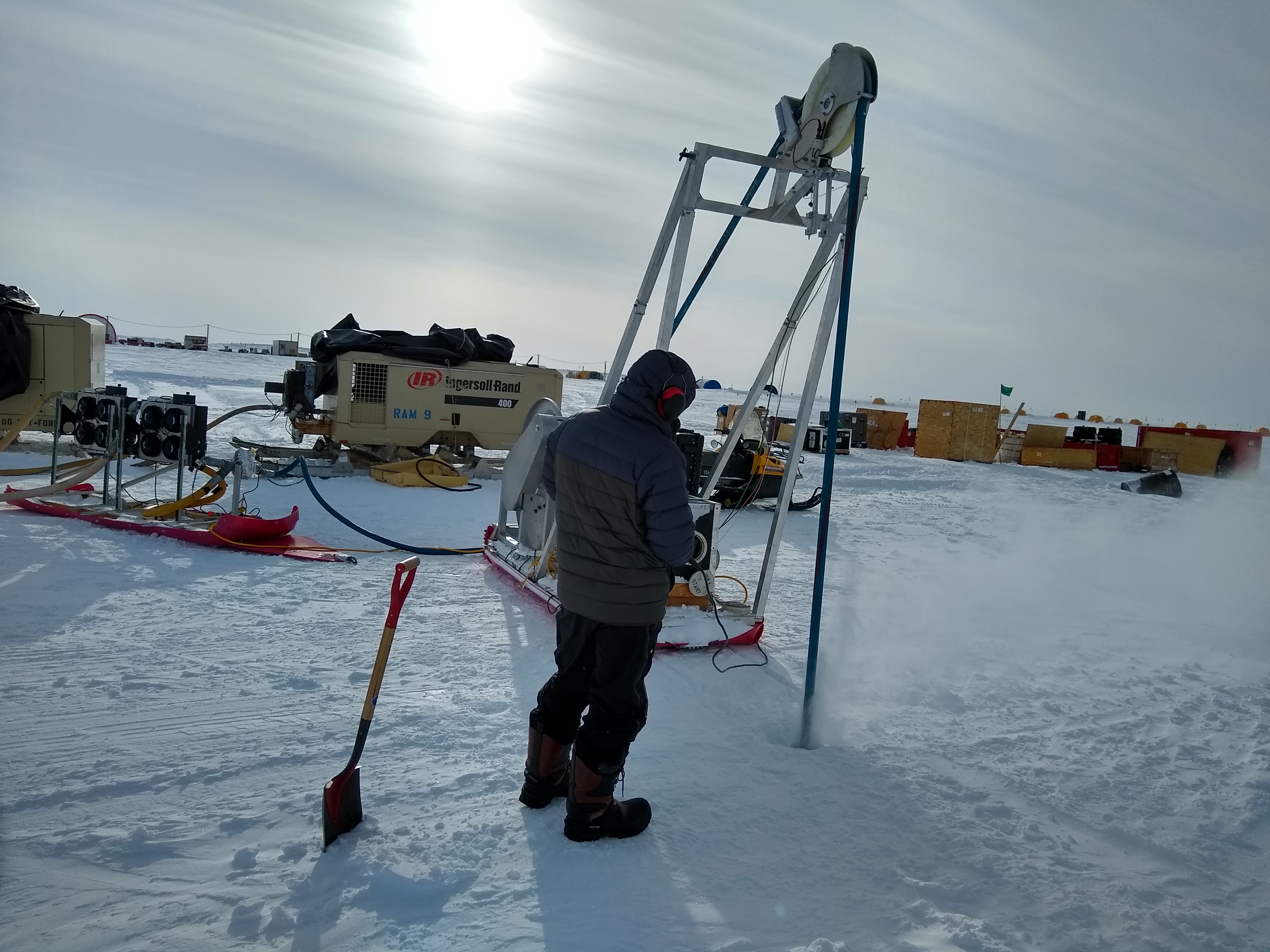

In preparation for the second GreenDrill season, a level wind option was purchased for the Agile Sub-Ice Geological (ASIG) Drill, as well as Kubota engine spares, drill rod end caps, rod scraper rings, Geoblock for the drill tent and generator tent flooring, and a replacement flow jet pump. IDP engineers also worked to design improvements for the ASIG Drill chip handling and filtration system. The Winkie Drill packer and the water swivel seal were tested, and filter socks, casing centralizers, and full-face and impregnated bits were purchased. Additional Winkie Drill casing was ordered and received to account for GreenDrill firn depth uncertainty, and work on a new insulated filtration tank was completed.

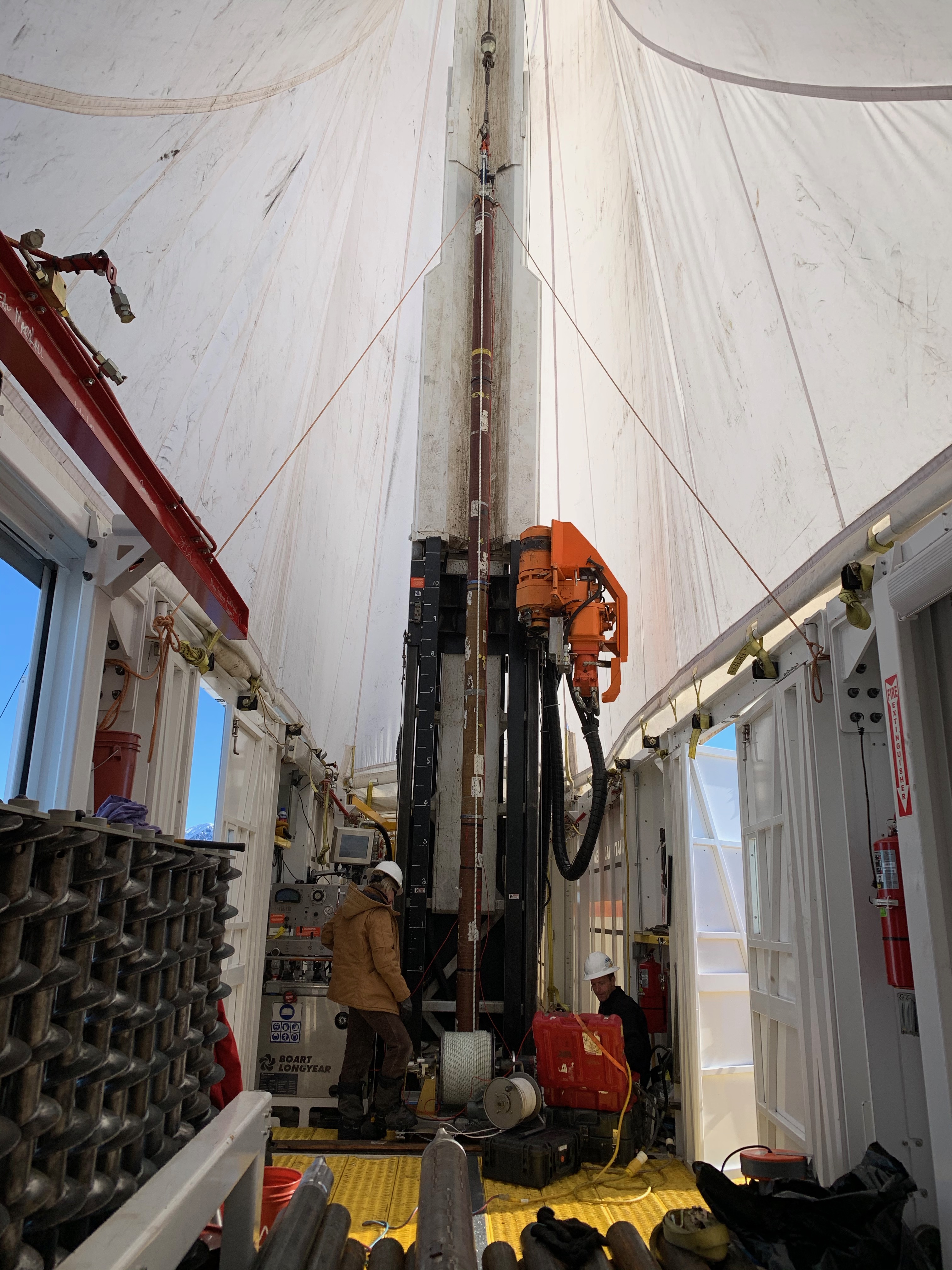

Work continued on new outer tubes for the Foro 400 Drill, and components for a new truss tower were received.