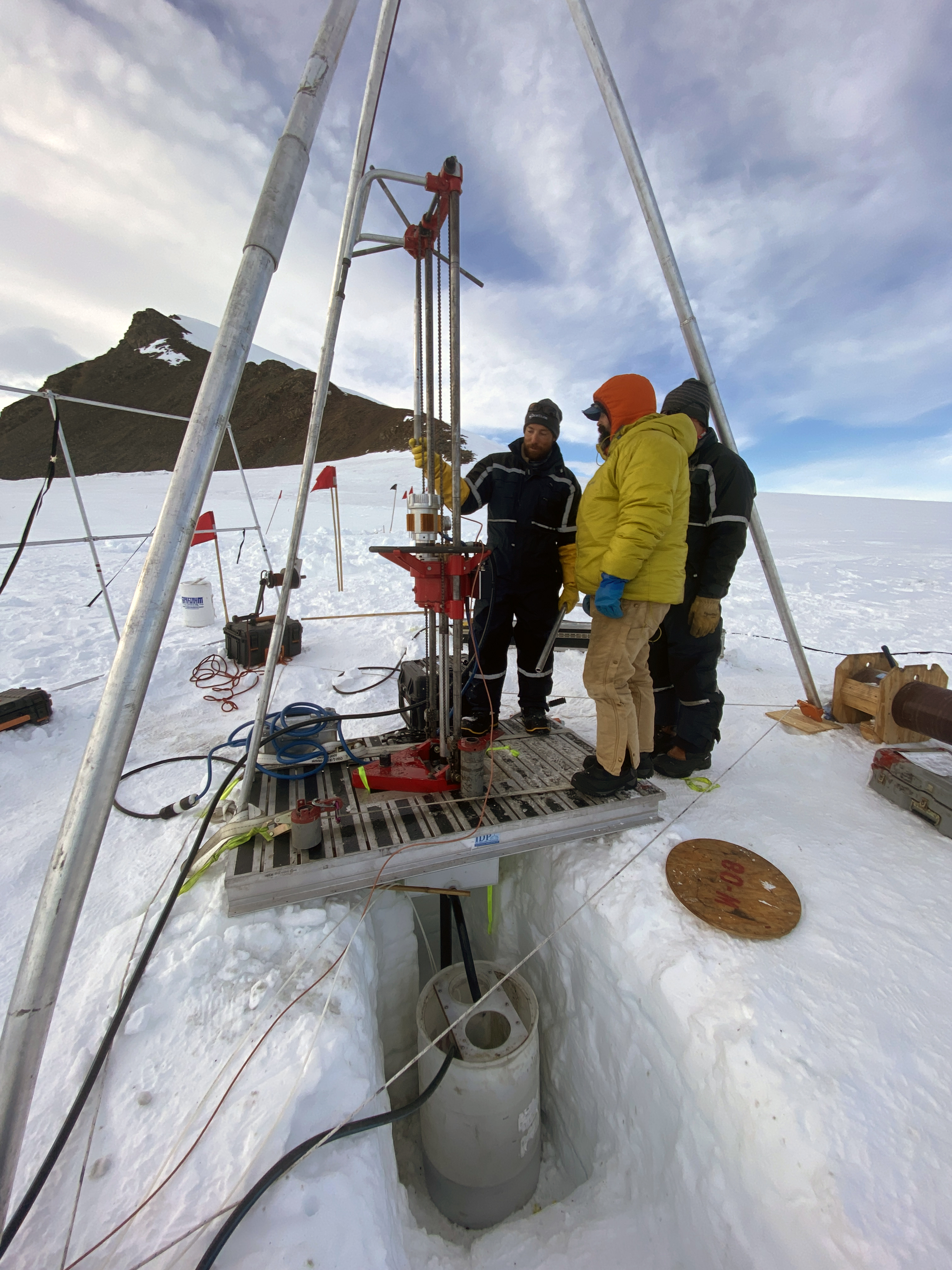

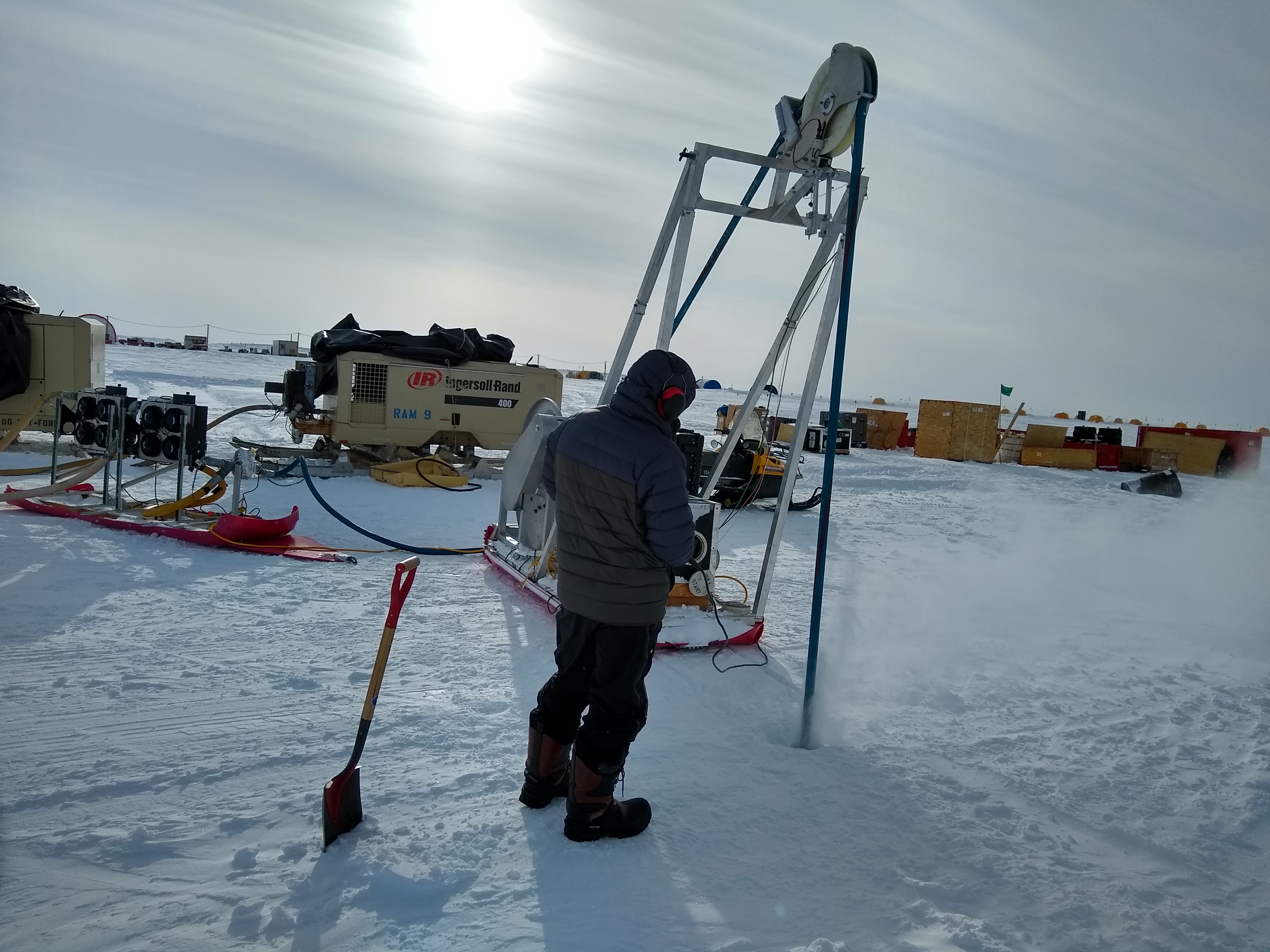

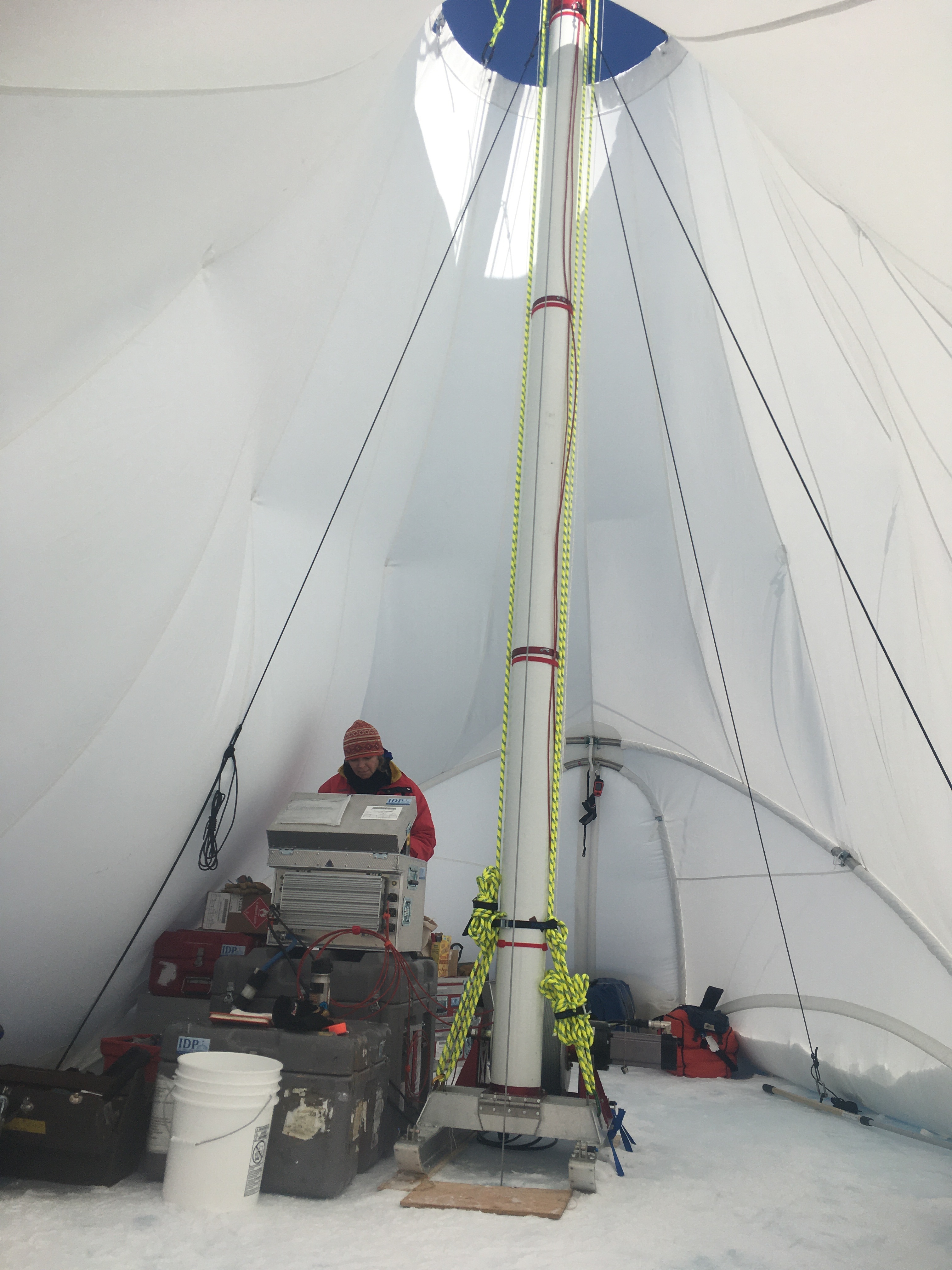

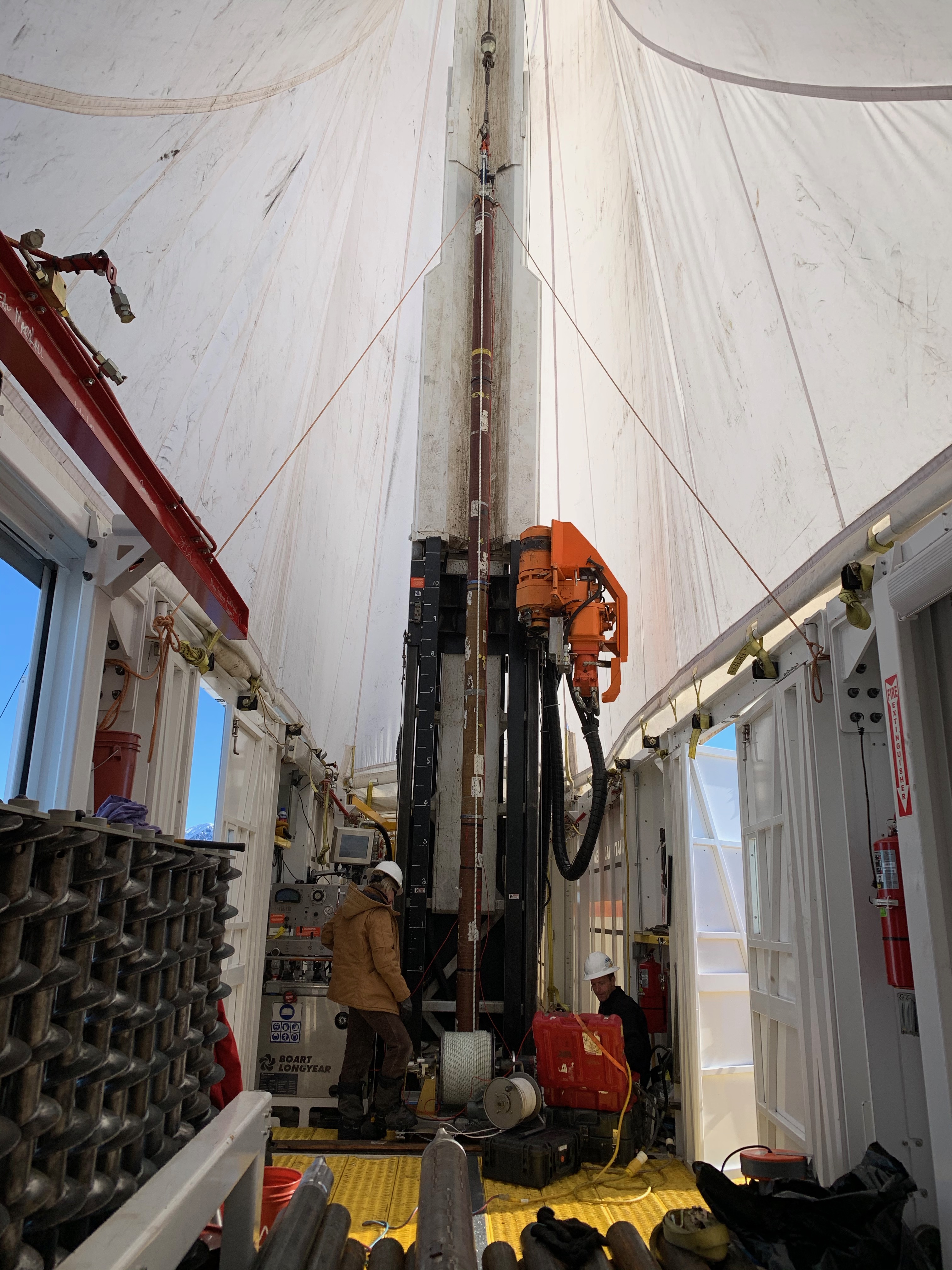

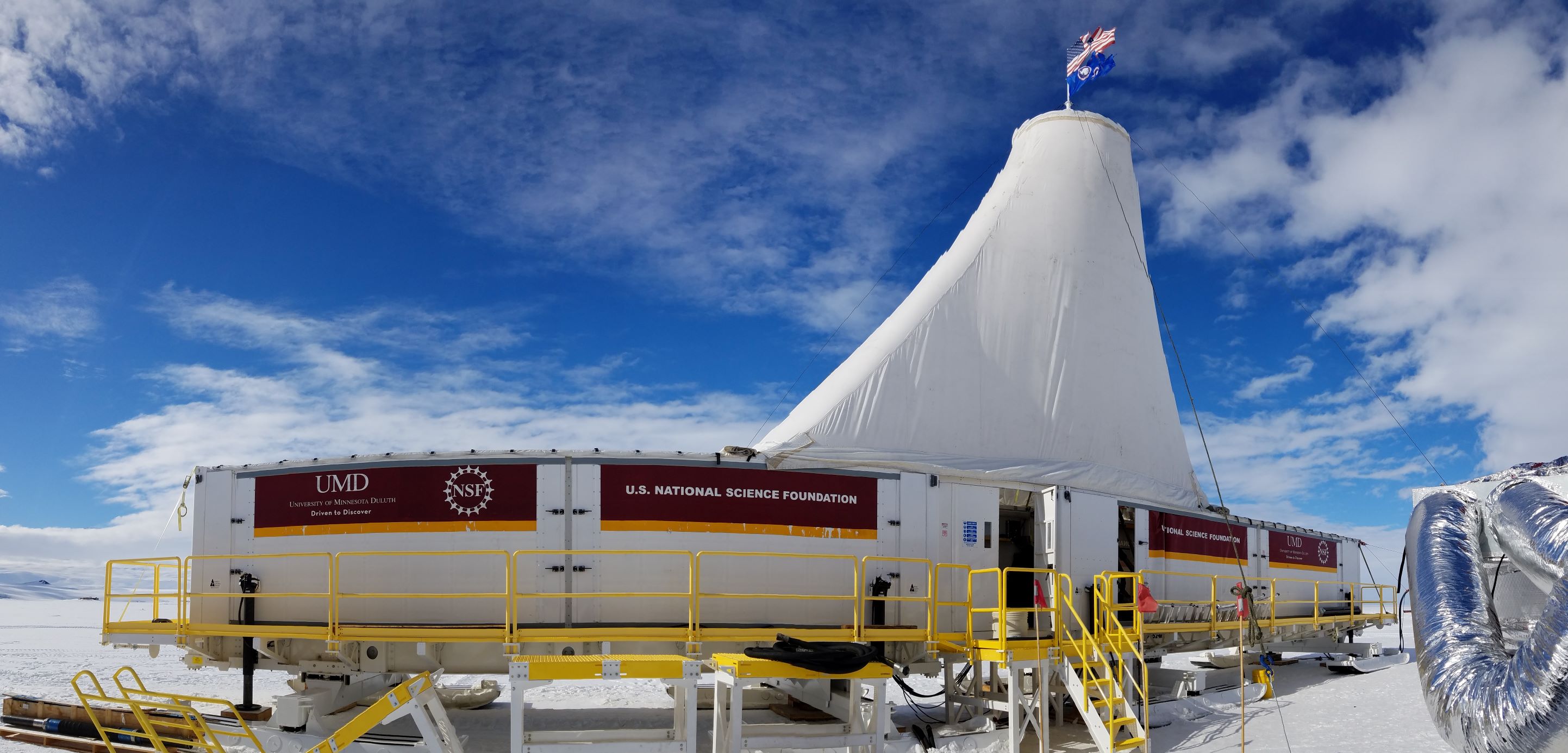

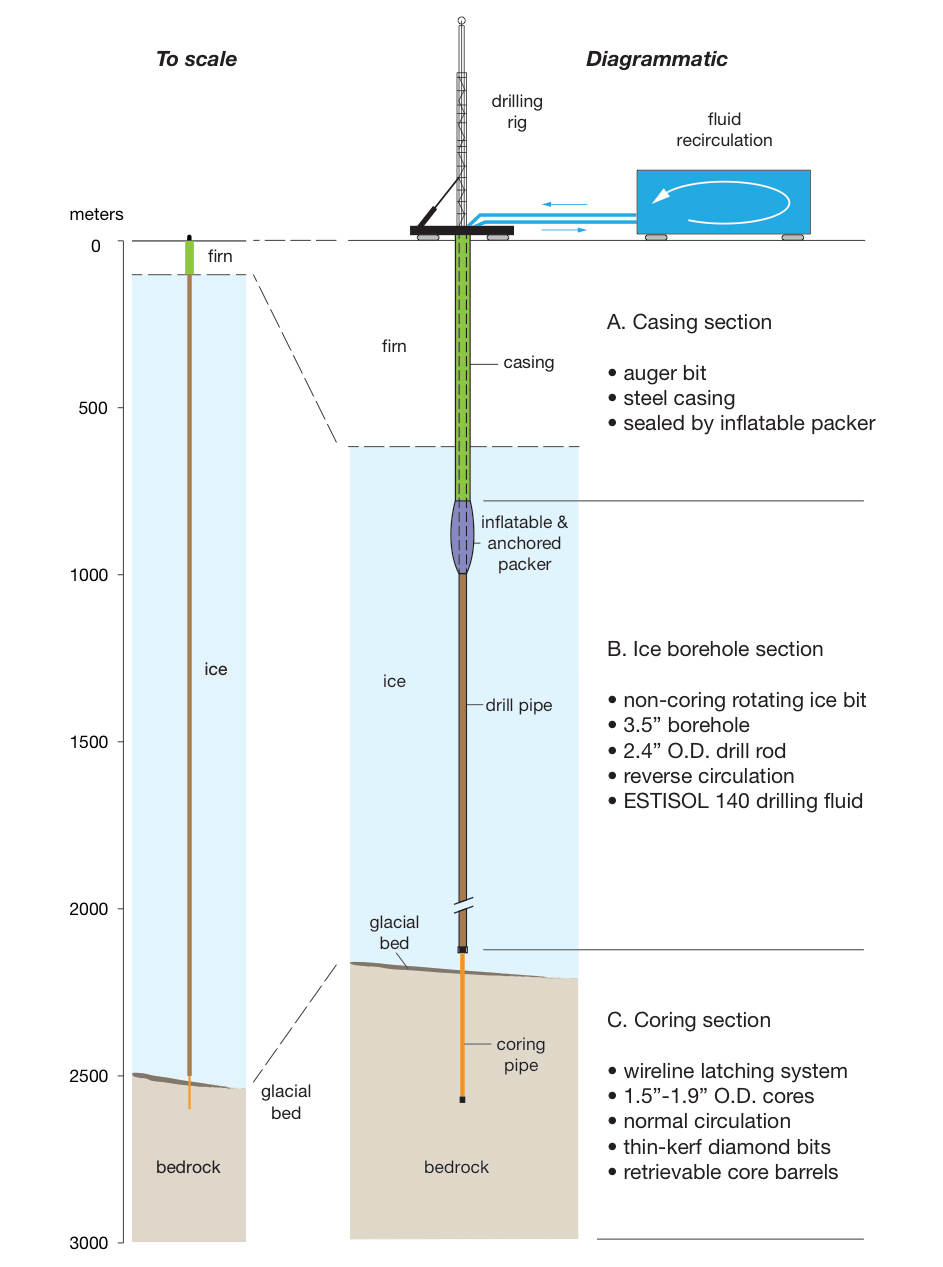

The U.S. Rapid Access Ice Drill (RAID) is ready for Antarctic ice-sheet exploration! RAID completed successful field trials in the 2019-20 austral season. Since then, RAID has completed a series of important tooling upgrades and technical improvements. With new developments in knowledge of subglacial materials and basal ice-sheet environment, new technologies and micro-instrument methodologies, discovery of very old (up to 4 m.y.) ice from blue ice fields, and an engaged new generation of young cryosphere and solid-earth scientists — now is a good time for a 2nd RAID Science Planning Workshop to reunite the community and articulate the future science that the community wants to do with RAID! Expression of interest and application forms are now officially open until July 15, 2024.

Conveners:

Sarah Shackleton (Woods Hole Oceanographic Institution)

John Goodge (Planetary Science Institute)

Allie Balter-Kennedy (Lamont-Doherty Earth Observatory)

Shuai Yan (University of Texas Institute for Geophysics)

Jeff Severinghaus (Scripps Institution of Oceanography)

Dates: September 25-27, 2024 (including half-day session for Early Career Researchers!)

Location: Herndon, Virginia (near Dulles airport)

Website: https://www.rapidaccessicedrill.org/2nd-raid-science-planning-workshop/

Expression of Interest Deadline: July 15, 2024

Registration Deadline: August 15, 2024

Costs: No registration fee. Meals will be provided to all participants during the Workshop. Rooms in the Workshop hotel will be available at a discounted rate (participants to pay on their own). Travel support is available for 15 Early Career participants (by application).

Workshop goals:

(1) rejuvenate & grow scientific user community for RAID;

(2) enable new generation of early-career scientists in cutting-edge Antarctic research;

(3) promote inter–disciplinary research synergies, including use of new cryosphere technologies;

(4) engage the geophysical community for reconnaissance, site selection & data analysis;

(5) help integrate RAID and COLDEX activities;

(6) stimulate new cross-disciplinary research & proposal collaborations;

(7) develop new concepts to support traverse platforms in Antarctica; and

(8) create a new Long-Range Science Plan for RAID based on community research goals & priorities for future drilling.

The workshop conveners seek a diverse group of participants for this NSF-funded workshop. Space is limited! Reserve your place and participate in this important workshop that will steer the future of RAID as an interdisciplinary research platform for deep ice-sheet access. An Expression of Interest (EOI) form is available for all participants. The deadline for submitting your EOI form is July 15, 2024. This includes an Application for Travel Support for Early Career Researchers.

For detailed information, costs, key dates, and a link to the EOI form, visit the workshop’s website:

https://www.rapidaccessicedrill.org/2nd-raid-science-planning-workshop/