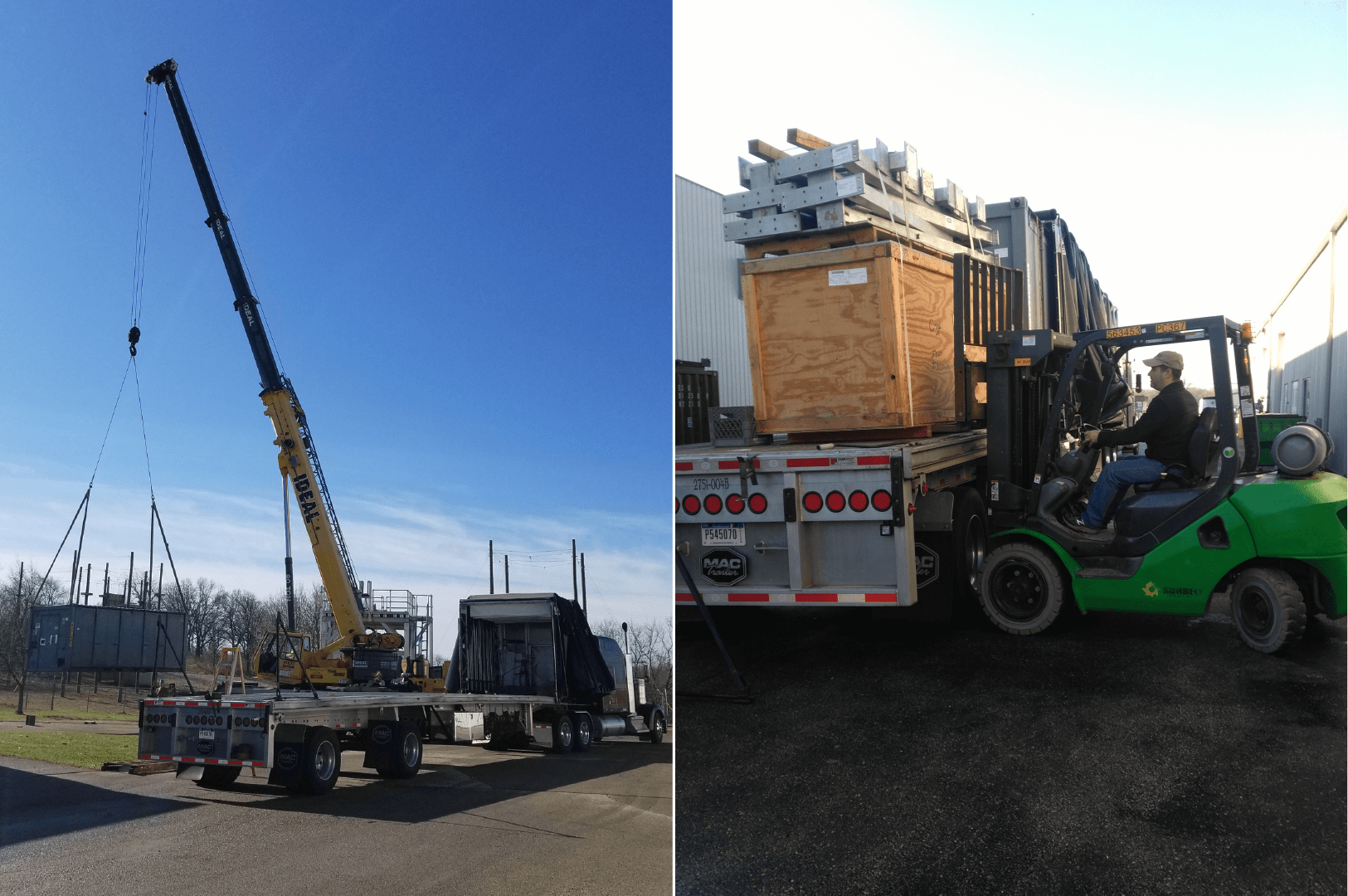

In early April, IDP-WI coordinated with staff at Port Hueneme to return cargo from Antarctica. Returned equipment included the Hand Augers used during the 2018-2019 season, the Intermediate Deep Logging Winch and the Sediment Laden Lake Ice Drill. In addition, several crates of DISC Drill equipment and the MECC (Mobile Expandable Container Configuration) machine shop returned after over a decade on the ice. The DISC Drill equipment and MECC were slowly removed from WAIS Divide on flights of opportunity.

Sediment Laden Lake Ice Drill

The MECC and Other Antarctic Cargo Returns

Sediment Laden Lake Ice Drill and Stampfli Drill Now Ready for PI Use

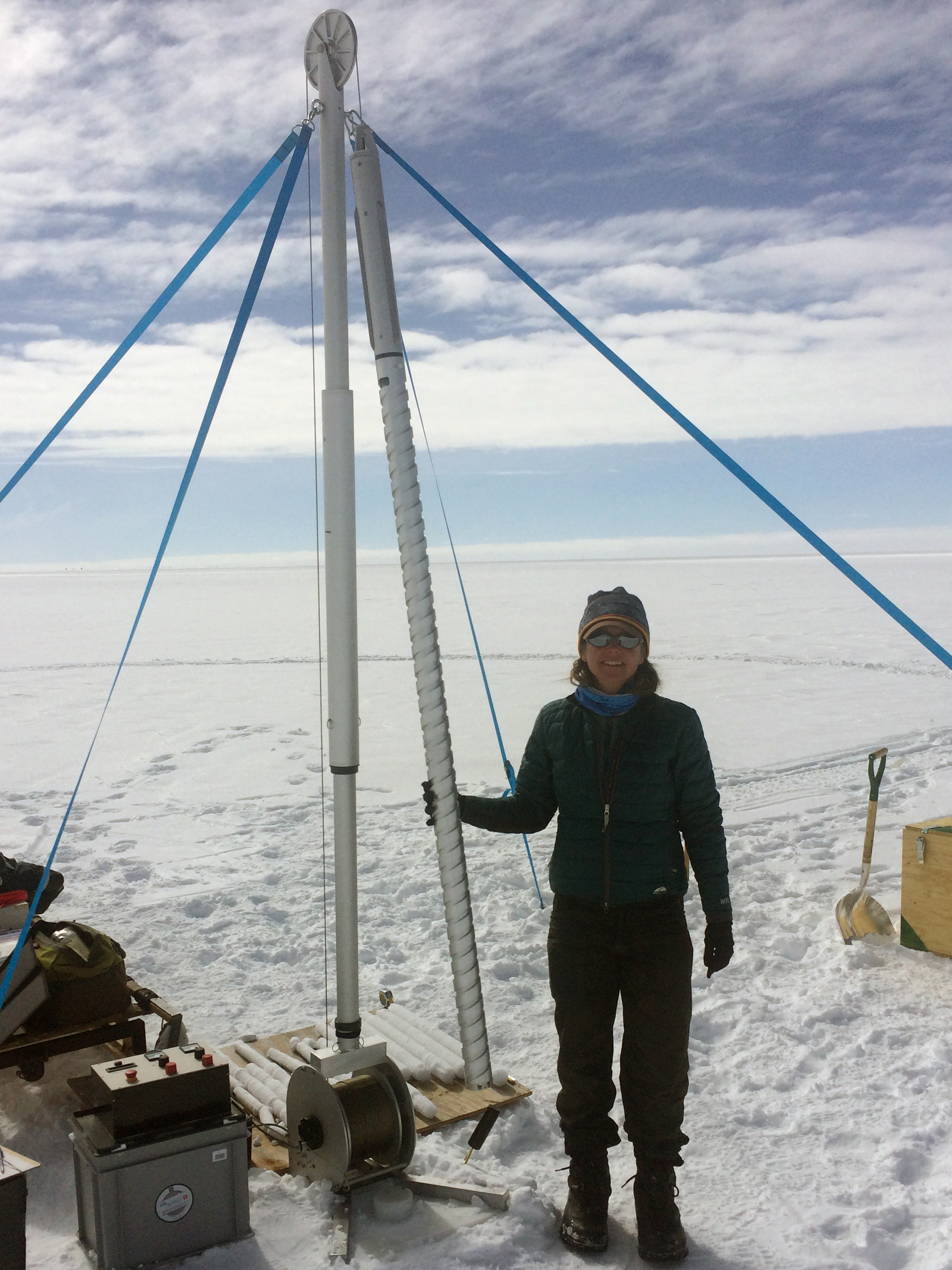

Sediment Laden Lake Ice Drill (SLLID)

The new Sediment Laden Lake Ice Drill (SLLID), designed and built by IDDO, is a 28kW hot water drill useful for creating holes with very little initial water, for freeing instrument cables from the ice, and for accessing equipment deployed beneath the ice. The drill is effective at drilling through sediment laden ice and allows safe servicing of science instruments deployed in the lakes and ocean.

For more information about the SLLID, contact IDPO-IDDO at Icedrill at Dartmouth dot edu.

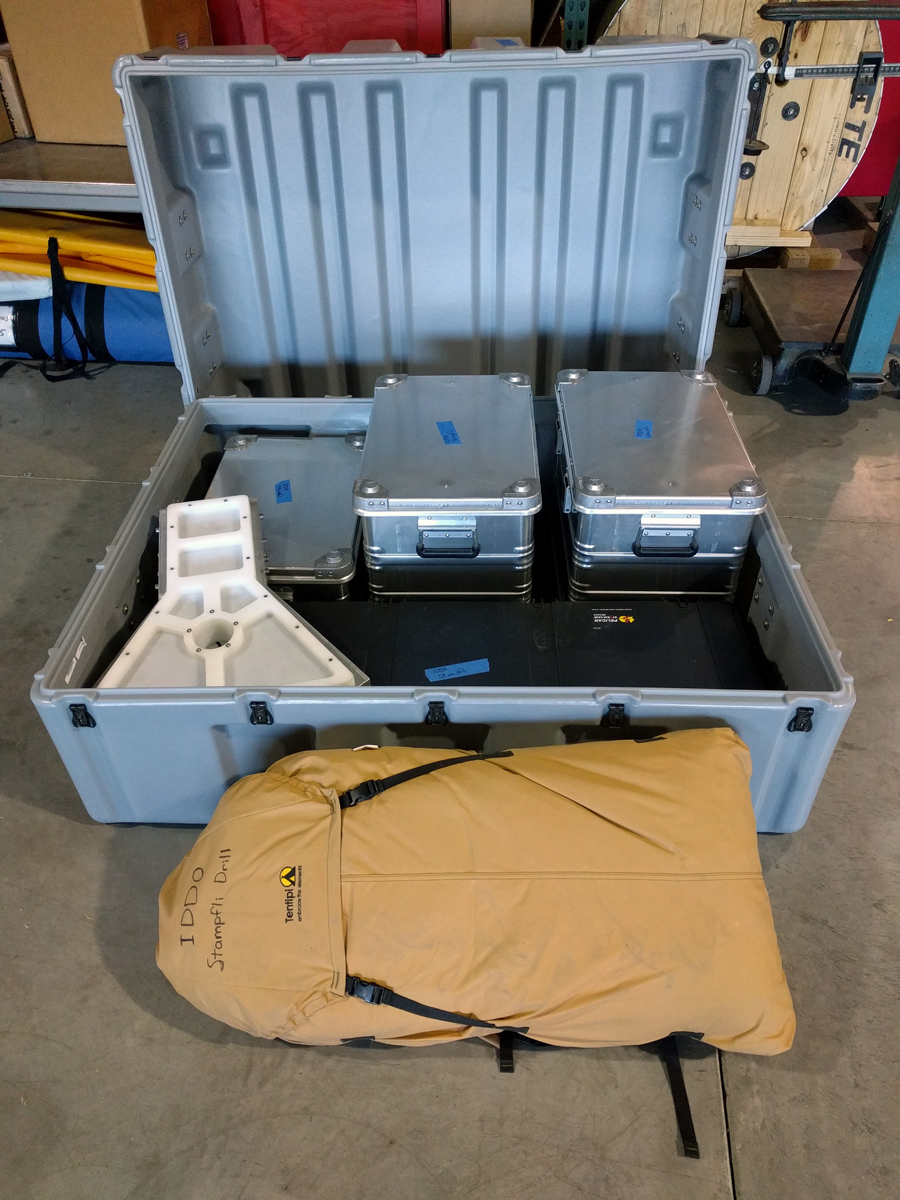

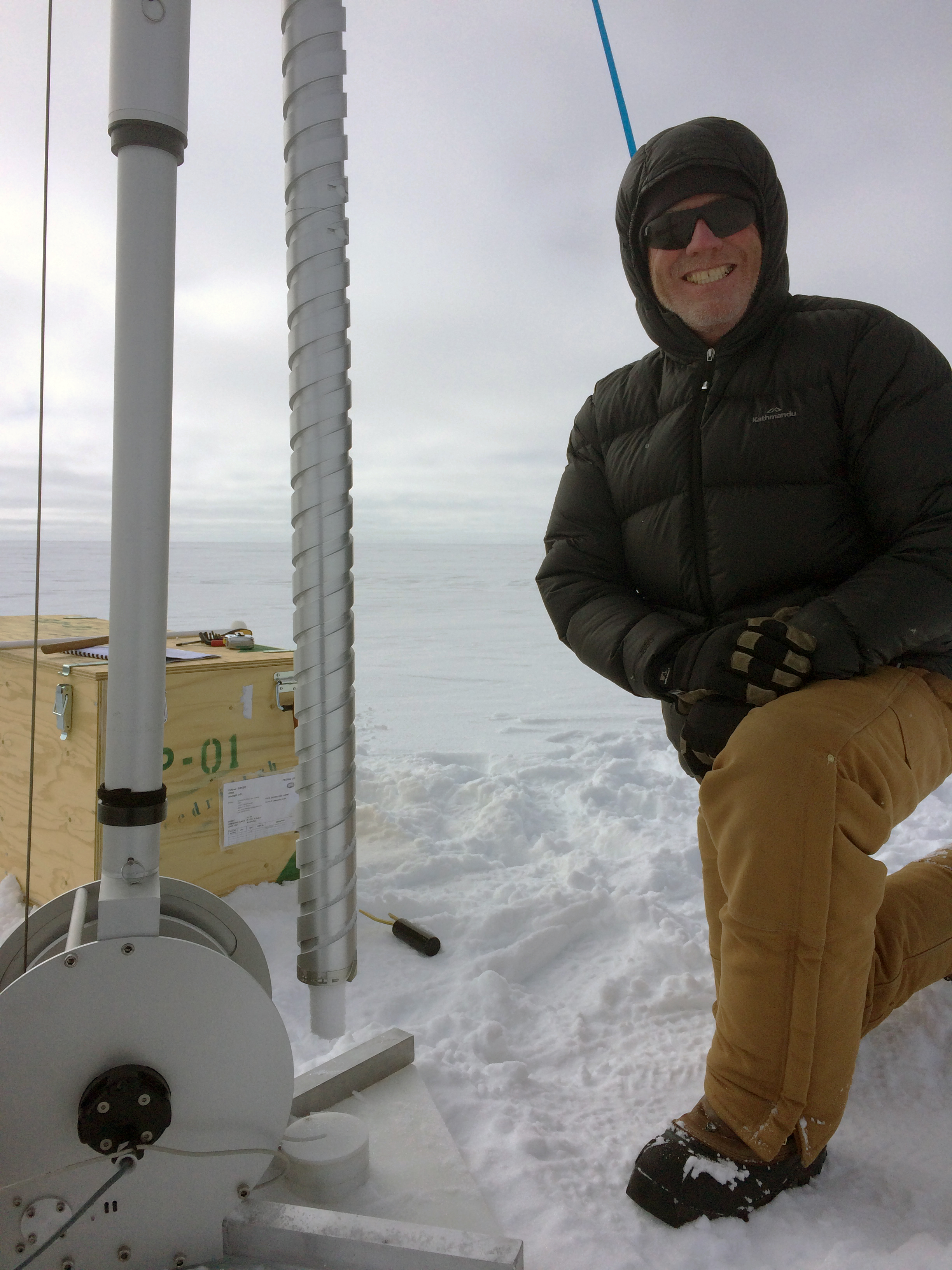

Stampfli Drill

The Stampfli Drill, a commercially-available shallow ice coring system purchased and received by IDDO in early 2017, is now ready for issue to investigators. Following a test of the system at Summit Station, Greenland, IDDO engineers made slight modifications to the commercial kit to include a more robust and replaceable steel cutter design and implemented a more efficient and lightweight packing strategy for remote deployments utilizing small aircraft and manpower for cargo movements. A tent is also available for use with the system. Science teams may operate the system on their own, with no drilling support from IDDO required, but are encouraged and welcome to visit IDDO in Madison, WI for pre-deployment hands-on familiarization training with the system if desired.

For more information about the Stampfli Drill, contact IDPO-IDDO at Icedrill at Dartmouth dot edu.

Equipment Development (2017 Summer)

Winkie Drill

In preparation for the upcoming field season in Antarctica, IDDO outfitted the Winkie Drill with a new electric motor and larger diameter core barrel for collecting 76 mm diameter cores. Testing of the updated drill is ongoing at the IDDO warehouse. The Winkie Drill will be shipped to Antarctica in September where it will be used to collect dirty ice cores in Ong Valley, Antarctica, to depths of up to 20 meters.

Stampfli 2-Inch Drill

IDDO shipped the very lightweight, agile Stampfli 2-Inch Drill system to Greenland for field testing in June in conjunction with a funded field project taking place at Summit Station. The small, solar-powered drill operated well during the field test, producing 58 meters of core. Based on the results of the field test, IDDO is working to make minor repairs and modifications to the drill, procure spare parts, and develop a lightweight packing strategy for this system. The system could be ready for deployment and PI operation as early as the 2017-2018 Antarctic field season.

Rapid Air Movement (RAM) Drill

A conceptual design for extensive weight reduction based on the revised science requirements was completed in July. The conceptual design was presented to community scientists Sridhar Anandakrishnan and Paul Winberry for input in early August. Following that external review and any necessary modifications to the design, IDDO plans to begin purchasing primary components for the lighter-weight RAM Drill system in September/October.

Sediment Laden Lake Ice Drill

The Sediment Laden Lake Ice Drill is a lightweight, field portable hot water drill for drilling through several meters of sediment-laden lake ice. Following the April external design review and the ordering of components in May, IDDO began assembly of the system in June and plans to complete simple functionality testing at the IDDO warehouse in late summer and early fall. The system could be ready for deployment and PI operation as early as the 2018 Arctic field season.

Foro 3000 Drill

The Design Review of the Foro 3000 Drill was held on June 6. The Design Review was a virtual meeting where IDDO presented the Conceptual Design for the drill, and community scientists Eric Steig, Ed Brook, and T.J. Fudge provided feedback from the scientist/user perspective. The Conceptual Design for the drill is now complete. The Foro 3000 Drill is conceptually the same design as the existing Intermediate Depth Drill, but with a depth range extended to 3000 meters and drill run length extended from 2-meters to 3-meters.

DISC Drill versus Foro 3000 Analysis

Per discussions between IDPO, IDDO and community scientists, the next deep U.S. ice coring project will likely target Hercules Dome, Antarctica. IDDO, with assistance from Antarctic Support Contract and IDPO, is currently working with community representatives on a DISC Drill versus Foro 3000 Drill analysis, to help determine which system should be used for drilling at Hercules Dome. The analysis results will be summarized into a report for use by NSF and the science community.

Winch Simulator

Following discussions with Mary Albert and PI Ryan Bay, and due to decreased interest by the science community in IDDO purchasing an off-the-shelf winch simulator unit or designing a custom unit, IDDO plans to design a simple simulator circuit for each logging winch in inventory. IDDO envisions providing these circuit designs to PIs for building at their own institutions. PIs could then perform limited pre-deployment testing on their logging tools; however, IDDO will still encourage PIs to travel to Madison to test logging tools on the actual winches to be deployed. IDDO plans to complete design of the simulator circuits by the end of October.

Equipment Development (2017 Spring)

Stampfli 2-Inch Drill

Late in PY 2016, and in response to the U.S. Ice Drilling Program Office Long Range Science Plan, IDDO ordered an off-the-shelf 2-Inch Drill system from Icedrill.ch. IDDO received the Stampfli 2-Inch Drill in April 2017 and completed an initial assembly of the equipment. IDDO is planning to send the very lightweight, agile system to Greenland for field testing in June in conjunction with PI Baker's project (see Field Support to 2017 Arctic Projects above).

Rapid Air Movement (RAM) Drill

The science requirements were finalized for the modification and upgrade to the current Rapid Air Movement (RAM) Drill, which is used to create ~100-meter deep shot holes for seismic exploration. The science requirements target a system capable of drilling as fast as the existing RAM Drill, but at a small fraction of the current system weight. Numerical modeling and testing was initiated during the quarter to identify both the hose and drill head configurations required to achieve the desired results. The science requirements are available on the IDPO-IDDO website at https://icedrill.org/equipment/rapid-air-movement-drill.

Sediment Laden Lake Ice Drill

The Sediment Laden Lake Ice Drill is a lightweight, field portable hot water drill for drilling through several meters of sediment-laden lake ice. During the quarter, the detailed Conceptual Design for the drill was completed, and the Design Review was held on 4/5/17. The Design Review was a virtual meeting where IDDO presented the Conceptual Design for the drill, and community scientists Peter Doran and Andrew Thurbur provided feedback from the scientist/user perspective, and Dennis Duling provided feedback and recommendations on the technical aspects. Major drill components were purchased in April with consideration of feedback from the review.

Foro 3000 Drill

IDPO led iterative discussions between community scientists and IDDO engineers on the formation of science requirements for extending the Intermediate Depth Drill (IDD) to a 3,000-meter depth capability. The extended depth IDD is referred to as the 'Foro 3000 Drill'. IDDO will develop a Conceptual Design for the Foro 3000 Drill during the third quarter. The Foro 3000 Drill's science requirements are available on the IDPO-IDDO website at http://icedrill.org/equipment/foro-3000-drill.

Equipment Development (2016 Winter)

Stampfli 2-Inch Drill

In late PY 2016, and in response to the U.S. Ice Drilling Program Long Range Science Plan, IDDO procured an off-the-shelf Fast Electromechanical Lightweight Ice Coring System (FELICS) 2-inch coring system from Dieter Stampfli in Switzerland. The Stampfli 2-Inch Drill was purchased to meet requests by the community for a very lightweight, PI-operable system capable of collecting core down to 100-meters depth. IDDO expects to receive the drill during the second quarter.

Rapid Air Movement (RAM) Drill

During the first quarter, IDDO worked with IDPO and community scientists to define the science requirements for intended modifications and upgrades to this drill system. The requirements target a system capable of drilling as fast as the existing Rapid Air Movement (RAM) Drill, but at a small fraction of the current system weight. The speed required is not achievable with double-walled drill rod used in a typical Reverse Circulation drill system. Alternative solutions, including two approaches using a hose like the existing RAM drill, are being analyzed. Numerical models and testing will be used to identify both the hose and drill head configurations required to achieve the desired results. A system-level concept will also be completed.

Sediment Laden Lake Ice Drill

IDDO initiated a detailed conceptual design late in the quarter for this new, very portable hot water drilling system. Design activities for the Sediment Laden Lake Ice Drill are expected to ramp up early in the second quarter.