With the IDP engineers at home for a second Antarctic season due to COVID-19 project postponements, the team took the opportunity to perform a full system shakedown of the Thermal Drill System on Lake Waubesa in Madison, WI, in mid-January. IDP Mechanical Engineer Grant Boeckmann was slated to deploy with the drill for an upcoming project on Quelccaya Ice Cap in Peru. As Boeckmann will be departing IDP in March to join the Centre for Ice and Climate in Denmark, the shakedown opportunity gave Mechanical Engineer Elliot Moravec the chance to pack the system, perform a full setup, including the tent, and drill a couple of ice cores into the foot-deep lake ice. The training proved very valuable and should set the Peru project up for great success.

Thermal Drill

Cold Wisconsin Winter and a Local Lake Enable Drill Testing and Training

2019 Arctic Field Season Support Completed

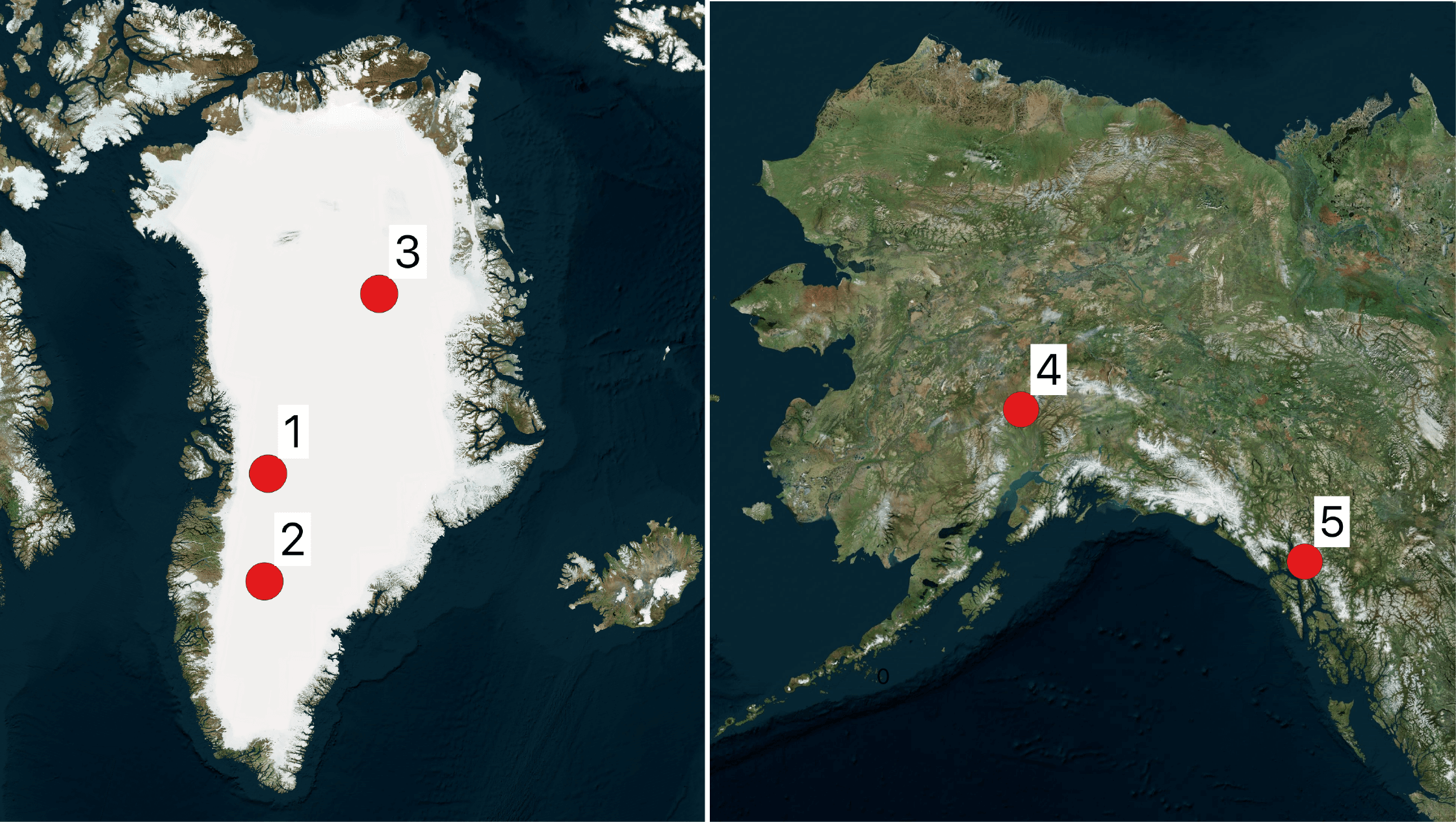

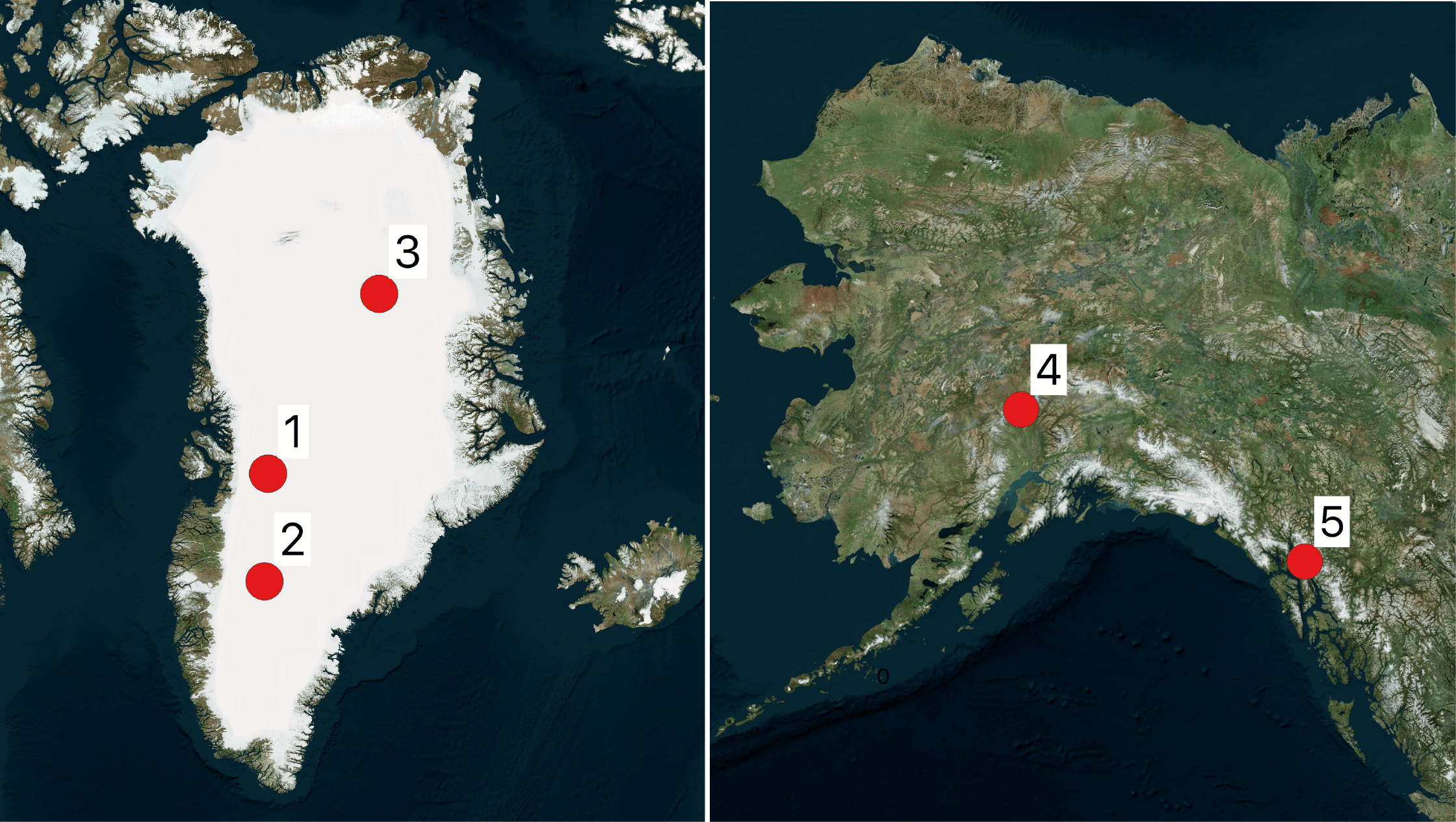

IDP successfully supported five projects during the 2019 Arctic field season.

(1) The Collaborative Research: Quantifying Heat/Mass Structure and Fluxes Through the Full Thickness of Greenland’s Percolation Zone project (PIs Harper and Humphrey; NSF awards 1717241 and 1717939) collected shallow firn cores in western Greenland using an IDDO hand auger and Sidewinder kit. The shallow cores were used to quantify firn density and provided access for temperature logging of the shallow firn thickness. The goal of the multiyear project is to use a combination of shallow and deep cores/boreholes to quantify the structure, thermal state, and heat fluxes through the full thickness of the firn column across a transect spanning western Greenland’s percolation zone. The researchers are using their own hot water drill to drill the deep (up to 100 meters) boreholes.

(2) The Collaborative Research: Refreezing in the Firn of the Greenland Ice Sheet: Spatiotemporal Variability and Implications for Ice Sheet Mass Balance project (PIs Rennermalm, Tedesco, and Hock; NSF awards 1604058, 1603331, 1603815) used an IDDO hand auger and Sidewinder kit for a third season in Greenland. During the multiyear project, the researchers collected several shallow firn cores from the southwestern sector of the Greenland Ice Sheet to investigate the stratigraphy, density, temperature, and liquid water content of the firn cover and its spatial and temporal variations.

(3) The Partnerships for Polar Science Education and Outreach in Greenland (JSEP) and Antarctica (JASE) project (PI Virginia; NSF award 1748137) encompasses two NSF-sponsored polar-focused programs – the Joint Science Education Project (JSEP) and the Joint Antarctic School Expedition (JASE) – that provide significant opportunities for training the next generation of STEM professionals and for polar-science outreach. JSEP, a project of the Joint Committee, was initiated in 2007 to educate students and teachers from Greenland, Denmark, and the U.S. The program brings US students together with Danish and Greenlandic students in Greenland where the group spends three weeks studying the causes and consequences of Arctic environmental change. As part of the JSEP program, an IDDO hand auger was used to expose the students to firn science (observing stratigraphic, density, and temperature changes with depth) at EastGRIP. JASE, a project in collaboration with the Chilean Antarctic Institute (INACH), takes U.S. students to Antarctica to work alongside Chilean students and examine Antarctica’s rapidly changing ecosystems.

(4) The EAGER: Exploration of the Denali Basal Ice Core Archive project (PI Kreutz; NSF award 1806422) returned to their 2013 ice core drill site and used the Stampfli Drill to collect a 50-meter long core from the summit plateau of Mount Hunter, Alaska. The researchers used a solar power system to power the Stampfli Drill during collection of the first ~45 meters of core when the sun was shining; the last 5 meters were collected during cloudy conditions, which required use of a generator to power the drill. The objective of the research is to understand the recent and past changes in summer temperature, snow accumulation, atmospheric circulation, and pollution in the context of the last 2000 years of natural variability in the North Pacific. In 2013 the researchers collected twin 208-meter long ice cores to bedrock from the same location (see Ice Bits 2013 Summer). This season’s 50-meter long core will be used to update the climate record from 2013 to 2019 and help aid in the interpretation of the deeper ice.

(5) The Electrothermal Drill Testing with the Juneau Icefield Research Program project (Ice Drilling Program) successfully field tested new modifications to the Thermal Drill. In late July and early August 2019, IDP Mechanical Engineer Grant Boeckmann, IDP Field Support Manager Anna de Vitry, and IDP contractor and Warehouse Manager Jim Koehler traveled to Juneau, AK, for a beneficial testing opportunity with the Juneau Icefield Research Program (JIRP). Utilizing the well-established logistics of the JIRP program, the IDP team was able to test new Thermal Drill modifications including a new 300-meter drill cable, a prototype ethanol delivery mechanism, and new heat rings. The IDP team successfully reached 294 meters and was able to refine operating procedures for the equipment.

Beneficial Proof-of-Concept Testing Conducted in Alaska

In late July and early August 2019, a team of three from IDP-WI traveled to Juneau, AK, for a beneficial testing opportunity with the Juneau Icefield Research Program (JIRP). The team consisted of IDP Mechanical Engineer Grant Boeckmann, IDP Field Support Manager Anna de Vitry, and IDP contractor and Warehouse Manager Jim Koehler. Utilizing the well-established logistics of the JIRP program, the IDP team was able to test new Thermal Drill modifications including a new 300-meter drill cable, a prototype ethanol delivery mechanism, and new heat rings. The team successfully reached 294 meters and was able to refine operating procedures for the equipment.

The Thermal Drill uses a ring-shaped heating element to melt, as opposed to mechanically cut, an annulus around the ice to be cored. This method of drilling is useful in ice warmer than about -10° C, where electromechanical drills are at risk of becoming stuck in the borehole from melting and refreezing of the surrounding ice. The Thermal Drill collects 76 mm (3-inch) diameter cores and has previously performed well in British Columbia, Alaska, and in southeastern Greenland.

Field Support to 2019 Arctic Projects

The second quarter saw the start of the 2019 Arctic field season. IDP is providing support to the following projects:

(1) The Quantifying Heat/Mass Structure and Fluxes through the Full Thickness of Greenland's Percolation Zone project (PI Harper; NSF award #1717241) will collect several shallow firn cores in western Greenland using a hand auger and Sidewinder kit. The cores will be used to quantify firn density, and the resultant boreholes will provide access for temperature logging of the firn column. The goal of the multiyear project is to use a combination of shallow and deep cores/boreholes to quantify the structure, thermal state, and heat fluxes through the full thickness of the firn column across a transect spanning western Greenland's percolation zone. The researchers are using their own hot water drill to drill the deep boreholes.

(2) The Refreezing in the Firn of the Greenland Ice Sheet 2019 project (PI Rennermalm; NSF award #1604058) will use a hand auger and Sidewinder kit to collect several shallow firn cores from the southwestern sector of the Greenland Ice Sheet to investigate the stratigraphy, density, temperature, and liquid water content of the firn cover. The project's goal is to better understand how the surface meltwater generated in the summer makes its way from its location on the ice sheet to the ocean. Two competing but not mutually exclusive theories are 1) the meltwater percolates into the ice sheet pores and is stored for a relatively long time. 2) The initial infiltrating meltwater refreezes at shallow depth in the firn, forming a hard pan that prohibits further infiltration. The project will test these two hypotheses through a combination of fieldwork, remote sensing from satellites, and modeling.

(3) The Partnerships for Polar Science Education and Outreach in Greenland (JSEP) project (PI Virginia; NSF award #1748137) is a multicultural polar science outreach program for high school students from Greenland, Denmark, and the USA. The program brings US students together with Danish and Greenlandic students in Greenland, where the group will spend several weeks studying the causes and consequences of Arctic environmental change. As part of the program, a hand auger will be used to expose the students to firn science (observing stratigraphic, density, and temperature changes with depth) at EastGRIP.

(4) The EAGER: Exploration of the Denali Basal Ice Core Archive project (PI Kreutz; NSF award #1806422) will return to their 2013 ice core drill site and use the Stampfli Drill to collect a 30- to 50-meter long core. The researcher's objective is to understand the recent and past changes in summer temperature, snow accumulation, atmospheric circulation, and pollution in the context of the last 2000 years of natural variability in the North Pacific. In 2013 the researchers collected twin 208-meter long ice cores to bedrock from the summit plateau of Mt. Hunter in Denali National Park. This season's 30- to 50-meter long core will be used to update the climate record from 2013 to 2019 and help aid in the interpretation of the deeper ice.

(5) The Thermal Drill Testing with the Juneau Icefield Research Program (JIRP) project is an internal IDP project. The Electrothermal drill, aka the "Thermal drill", is a mechanical ice coring drill based on the agile 4-Inch drill but with the addition of an electrically heated ring that enables coring in temperate ice that is close to the pressure melting point. Following planned system upgrades in PY 2018, including a new 300-meter long cable, new heat rings and an ethanol delivery mechanism, IDP is conducting a three-week test of the Electrothermal Drill system in Alaska in conjunction with other JIRP activities and established logistics. Following the test, IDP will inspect and repair the Electrothermal Drill equipment and make any necessary modifications.

Beneficial Testing Opportunities Conducted Near Madison, WI

In late February and early March, IDP-WI supported a test of PI Dale Winebrenner's Ice Diver probe in the prototype test well located on the UW Physical Sciences Lab campus outside of Madison. Record-breaking low temperatures in Wisconsin during the week-long test provided a true Antarctic field experience. The team reached 10-meters depth in the 13-meter deep hole and brainstormed beneficial modifications to implement before further testing in Greenland. Following that effort, IDP took an opportunity to test the Stampfli Drill, a newer drill for IDP, but most often used in firn, to determine its suitability for drilling pilot holes for the Winkie Drill on Thwaites Glacier, Antarctica. In the absence of an outer barrel, chip transport was found to be inefficient when drilling in ice. IDP engineers have identified possible modifications to improve the system, such as the addition of a ribbed outer barrel, replacement of the aluminum cutter heads with stainless steel heads and the addition of variable pitch shoes to control penetration based on borehole conditions. For the upcoming Antarctic field season, and after discussion with ASC and PI Brent Goehring, IDP will deploy an Eclipse Drill for drilling of the Winkie Drill pilot holes but may look to upgrade the lighter weight Stampfli Drill to accomplish this task in the future as time and funds allow. IDP was also able to test the performance of a new Thermal Drill cable, new heat rings, and a tool designed by IDP engineers to more efficiently remove cores from the core barrel.

Equipment Updates (2018 Summer)

Foro 3000 Drill

IDDO continued initial development tasks for the Foro 3000 Drill system during the third quarter. Detailed design of the winch drum and level wind are in process. Sizing calculations were made and a design initiated for the chip melter system. Sonde assembly drawings were largely completed. Design work is expected to ramp up in the fourth quarter in preparation for a Detailed Design Review in late September.

Foro Drill

Anti-torque section assembly was largely completed and motor section assembly was initiated on the Foro Drill. Cabling was completed for the control box and drill motors were ordered. Shipping cases were received for the sonde, tower, and winch. Cutter head assemblies, spare cable terminations, and anti-torque slip rings were also received. Some assembly and testing have been delayed in light of work on higher priority projects, but procurements are largely complete.

Rapid Air Movement (RAM) Drill

Continued acceleration of RAM Drill design, procurement, and in-house testing. The system was prepared, packed and shipped to Scotia, NY in late June. In early July, IDDO received an Expedition Permit from the Government of Greenland, and a two-week field test was subsequently completed at Camp Raven in late July.

Intermediate Depth Drill

Models and drawings were completed for the winch cable terminations and spare cable termination kits were received for the Intermediate Depth Drill. System maintenance continues at a slow pace, as does the testing and troubleshooting of the Mage Controls components. The components, returned to Mage Controls at the end of the second quarter, are expected back at IDDO early in the fourth quarter.

Winkie Drill

Borehole casing was specified and purchased in preparation for the Winkie Drill's first use in West Antarctica at a drill site with overlying firn. IDDO sought information from international colleagues regarding methods to seal the bottom of the casing to the ice. Packer components, benchtop testing for compressed air inflation, and detailed models of packer components were also researched.

Blue Ice Drill (BID)

Maintenance and upgrade tasks were largely completed during the quarter for the BID-1. The drill was subsequently cleaned, packed and shipped for the upcoming Law Dome project in Antarctica. IDDO continued communication with BID tent vendor Fabricon. Engineer Tanner Kuhl visited the vendor's location in mid-July to review the design and progress thus far, and the tent was completed in mid-August.

Thermal Drill

The Engineering Requirements document for the Thermal Drill was approved and released. IDDO engineers worked to identify, procure and test some thermal and power limiting materials and components during the quarter. New heat rings were specified, as the old model is now out of production, and a number of new rings were ordered late in the quarter.

Hand Augers

Planned modifications for the cleat and locking break components of the SideWinder units were implemented on all five kits in inventory. Equipment was returned from Svalbard and Greenland and was repaired as needed. Orders were subsequently placed for replacement of a few components that were stuck in the ice during the 2018 Arctic fieldwork.

4-Inch Drills

Maintenance was completed for the 4-Inch Drill system that returned from Antarctica. One core barrel set was modified to match beneficial modifications made to another barrel set in inventory. An improved cable keeper for the crown sheave was designed, fabricated and implemented.

Eclipse Drills

A more robust top cover and new side panels were installed on the Eclipse Drill traversing system. Beneficial updates were made to the Operator's Manual. Small tools such as strap wrenches and sharpening stones were purchased for use in the field.

Equipment Updates (2018 Spring)

Foro 3000 Drill

IDDO continued initial development tasks for the Foro 3000 Drill system during the second quarter. Modifications were made to the Intermediate Depth Drill cutter head design that may make it possible to perform multiple core breaks during one drill run. This will be of value when drilling brittle ice with the Foro 3000 Drill. Detailed design of the winch drum was also initiated during the quarter.

Foro Drill

Fabrication of the Foro Drill core barrels was completed and all parts for the anti-torque and motor sections were ordered except for the actual drill motors for which IDDO expects to pursue quotes in the third quarter. The magnetic slide hammers were assembled, and load testing of the sled and hitch was completed. Shipping cases for the sondes, tower, and winch were also ordered.

Rapid Air Movement (RAM) Drill

Acceleration of RAM Drill design and procurement tasks continued to accommodate a potential test of the system in Greenland during summer 2018. All major component orders have been placed and electrical testing of the sonde was initiated. Initial testing for air pressure losses was completed.

Thermal Drill

Updated science requirements for IDDO's Thermal Drill were finalized at the end of February. A thermal or power limiting feature is being planned as part of the system upgrades, to help prevent premature heat ring failure. A benchtop testing procedure was initiated during the quarter and a number of thermal/power limiting options are under consideration. A manufacturer of suitable heat ring elements has been identified, and a core removal tool was designed and built making use of magnets to disengage the core dogs.

Intermediate Depth Drill (IDD)

The new 1650-meter long winch cable was spooled on the winch drum and was terminated, and the level wind controls were modified to work with the current emergency-stop system. Acceptance testing and troubleshooting of the Mage control system components continued. At the end of the quarter, the IDD's control system components were shipped back to Mage for further tuning.

Winkie Drill

IDDO is pursuing upgrades to integrate borehole casing with the current Winkie Drill system for a planned Thwaites Glacier project. Technology from the rock drilling industry and international ice drilling community is being researched.

Blue Ice Drill (BID)

Redesigned components for the BID tripod feet were received and installed during the quarter. A custom tent enclosure manufacturer was identified in April, and design of a tent and its integration with the BID tripod system has been initiated.

In summer 2017, IDDO worked to begin fabrication of a second BID-Deep system (for wide-diameter ice coring to 200 meters), based on user demand and per a directive in the IDPO Long Range Science Plan 2016-2026. Fabrication of the second system was initially scheduled for completion in Program Year (PY) 2018. However, there is no longer a funded science project this year that requires a second BID-Deep system, and therefore completion of the second BID-Deep system has been postponed to enable work on higher-priority projects in PY 2018.

Foro 700 Drill

The IDPO Science Advisory Board identified in the IDPO Long Range Science Plan 2015-2025 a priority need to alter the surface equipment for the existing Intermediate Depth Drill to make a drilling operation that is less logistically intensive, to be used for ice coring at sites with limited logistics and with two months or less time on site. From discussions organized by IDPO with iterative discussions between IDPO, scientists, and IDDO staff, the science requirements for a 'Foro 700 Drill' were completed during the second quarter. The next step is to develop the conceptual design for the drill, which could possibly happen in PY 2019 pending availability of funds and project prioritization.

Equipment Updates (2017 Winter)

Foro 3000 Drill

IDDO kicked off development of the Foro 3000 Drill system during the first quarter. The Foro 3000 concept builds on the Intermediate Depth Drill (IDD) system and will allow for deep coring down to 3000 meters depth. A detailed task list was developed and other important documentation such as the Project Management Plan and the Engineering Requirements were completed and formally released. Detailed design work was completed for updates to the IDD's anti-torque components to allow for accommodation of a larger-diameter cable. The IDD sonde design was also modified to allow for recovery of 3-meter long cores per drill run.

Foro Drill

Several Foro Drill components were received that were ordered in late PY 2017, including a spare winch gearbox, winch motor, load pin and tower tubing. Control box functionality testing was initiated. The sonde design is now finalized and fabrication has begun.

Rapid Air Movement (RAM) Drill

Design and procurement tasks were accelerated to accommodate a potential test of the Rapid Air Movement (RAM) Drill system in Greenland during summer 2018. Component purchases included a new hose reel and downhole motors and controllers. Initial subsystem testing has begun.

Thermal Drill

IDDO engineers researched potential vendors for new heat rings, as the former model is now out of production. IDDO also worked with IDPO and community scientists (Rick Forster, Lora Koenig, Peter Neff, Eric Steig) to iterate on a Science Requirements document before planned modifications are made to extend the Thermal Drill's depth capability to 300 meters, as is called for in the Long Range Science Plan.

Intermediate Depth Drill

Many Intermediate Depth Drill components ordered in late PY 2017 were received, including a spare winch gearbox, spare levelwind rollers, borehole pressure sensors, load pins with internal amplifiers, and the long-awaited Mage control system components.

Greenland Firn Aquifer Project Battles Tremendous Snowfall

In late March, IDDO engineer Josh Goetz deployed with the Greenland Firn Aquifer project science team (Forster, PI) to Kulusuk in Southeast (SE) Greenland. After issues with poor weather and with helicopter availability, the team made it into the icecap in SE Greenland and drilled the first of four planned holes into the firn aquifer layer using the Electrothermal Drill. A thermistor string was placed in the borehole, and while the plan was to then move to a second site, an unusually heavy pair of storms descended upon the camp, dropping approximately 2.5 meters of snow in just five days, precluding movement to the second site. Shown in the photo below, snow has completely covered the drill winch and nearly half of the 3.2 meter tall drill tower. It is surmised that the first storm encountered was the remnant of a hurricane that formed off the coast of Newfoundland.