In PY 2014, IDP completed the design and fabrication of a Foro 1650 Drill (previously referred to as the Intermediate Depth Drill or IDD). With assistance from international colleagues, IDP modified the existing design of the Hans Tausen Drill and built a new system. The system was field-tested outside of Summit Station, Greenland, in spring 2014 and was used in the successful completion of the SPICEcore project near South Pole Station from 2014-2016, where a total of 1,751 m of core was collected. The drill was originally designed to reach a depth of 1,500 m. Following a post-project analysis of the SPICEcore project, IDP has set the cable limit for the current winch drum at 1,700 m capacity, which allows for drilling to approximately 1,650 m depth. This maintains adequate safety margins for the drum flanges and mitigates the risk of system damage should the level wind not spool the cable perfectly every time. While the system was originally called the Intermediate Depth Drill or IDD, the name was updated in 2019 to signify the shared sonde design of other IDP drill systems (e.g. Foro 400, Foro 3000). IDP also procured new 4-conductor cables following the SPICEcore project to mitigate operational issues experienced during the project. IDP also pursued a resign of the drill system electronics to implement beneficial sensors for temperature, pressure, and inclination. The drill system electronics design is now shared between the Foro 1650 and the Foro 3000, making use of proven, off-the-shelf parts wherever possible.

Equipment Details

| Name | Foro 1650 Drill |

|---|---|

| Type |

Type

Ice coring

|

| Number in Inventory |

Number in Inventory

1

|

| Max. Practical Depth |

Max. Practical Depth

1650 m

|

| Hole Diameter |

Hole Diameter

129.6 mm (wet hole)

126 mm (dry hole)

|

| Ice Core Diameter |

Ice Core Diameter

98 mm (3.85 inches)

|

| Ice Core Length |

Ice Core Length

2.0 m

|

| Rock Core Diameter |

Rock Core Diameter

[NA]

|

| Rock Core Length |

Rock Core Length

[NA]

|

| IDP Driller Required? |

IDP Driller Required?

Yes, 3+ (number of drillers required depends on desired drilling depth and drilling schedule)

|

| Drill Fluid Required? |

Drill Fluid Required?

Yes

|

| Trench Required? |

Trench Required?

Yes |

| Power Requirements/Source |

Power Requirements/Source

35 kW, 460 V, 3-phase generator

|

| Estimated Drilling Time |

Estimated Drilling Time

1,500 m - 85 days (assumes 24 hour operations) |

| Helicopter Transportable? |

Helicopter Transportable?

Yes (see system weight/cube below)

|

| Light Aircraft Transportable? |

Light Aircraft Transportable?

Yes (see system weight/cube below)

|

| Shipping Weight |

Shipping Weight

27,000 lbs (does not include drilling fluid, generator, generator fuel, or personnel) |

| Shipping Volume (Cube) |

Shipping Cube

1,875 |

Documents

| Citation | Year |

|---|---|

| NSF Ice Drilling Program (2025) Foro 1650 Operations and Maintenance Manual. 1-46. | 2025 |

| Jay A Johnson, Tanner W Kuhl, Grant Boeckmann, Chris J Gibson, Joshua Jetson, Zachary Meulemans, Kristina R Slawny, Joseph M Souney (2021) Drilling operations for the South Pole Ice Core (SPICEcore) project. Annals of Glaciology, 62, (84), 75-88. doi: 10.1017/aog.2020.64. https://doi.org/10.1017/aog.2020.64 | 2021 |

| Joseph M Souney, Mark S Twickler, Murat Aydin, Eric J Steig, TJ Fudge, Leah V Street, Melinda R Nicewonger, Emma C Kahle, Jay A Johnson, Tanner W Kuhl, Kimberly A Casey, John Fegyveresi, Richard M Nunn, Geoffrey M Hargreaves (2021) Core handling, transportation and processing for the South Pole ice core (SPICEcore) project. Annals of Glaciology, 62, (84), 118-130. doi: 10.1017/aog.2020.80. https://doi.org/10.1017/aog.2020.80 | 2021 |

| Pavel Talalay (2021) Long-Term Stability of Deep Boreholes in Ice Filled with Estisol-140 Drilling Fluid. IceCube Polar Science Workshop, 19-20 January 2021, 1-13. | 2021 |

| Eric J Steig, TJ Fudge, Ryan Bay, Robert Hawley, IDPO (2018) Science Requirements: Foro 3000 Drill. 1-3. | 2018 |

| Kyle Zeug (2018) Replicate Coring System for 98mm Electromechanical Drill - Whipstock Conceptual Documentation. 1-16. | 2018 |

| Kimberly A Casey, TJ Fudge, Thomas A Neumann, Eric J Steig, Marie GP Cavitte, Donald D Blankenship (2014) The 1500 m South Pole ice core: recovering a 40 ka environmental record. Annals of Glaciology, 55, (68), 137-146. doi: 10.3189/2014AoG68A016. https://doi.org/10.3189/2014AoG68A016 | 2014 |

| Jay A Johnson, Alexander J Shturmakov, Tanner W Kuhl, Nicolai B Mortensen, Chris J Gibson (2014) Next generation of an intermediate depth drill. Annals of Glaciology, 55, (68), 27-33. doi: 10.3189/2014AoG68A011. https://doi.org/10.3189/2014AoG68A011 | 2014 |

| IDDO (2013) Intermediate Depth Drill Final System Engineering Design Review (20 March 2013). 1-87. | 2013 |

| IDDO (2012) Intermediate Depth Drill Science Review (17 October 2012). 1-61. | 2012 |

Photos

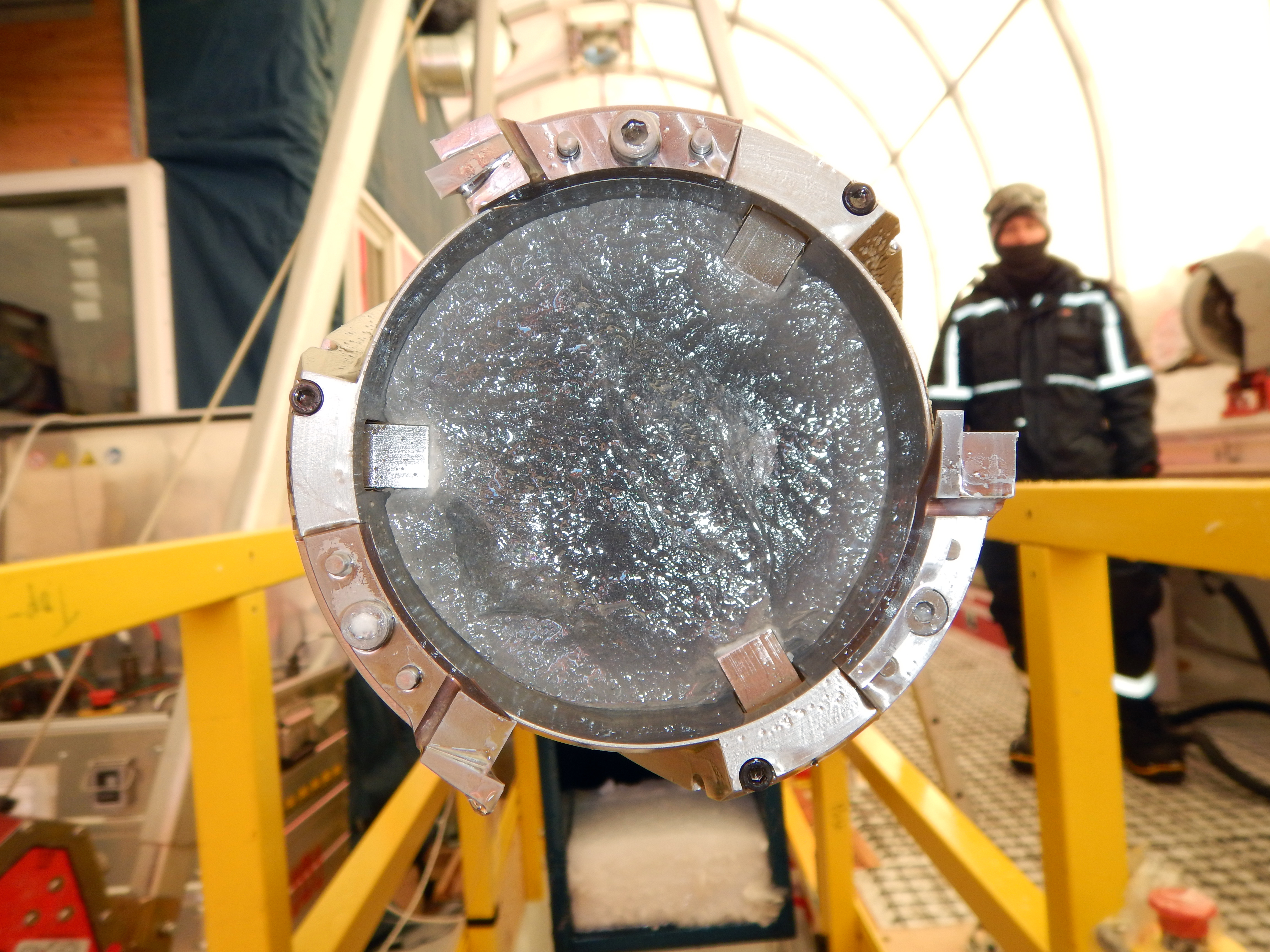

The very last run of ice from the South Pole Ice Core project inside the barrel of the Intermediate Depth Drill. The ice is from 1751 meters depth. Credit: Jay Johnson

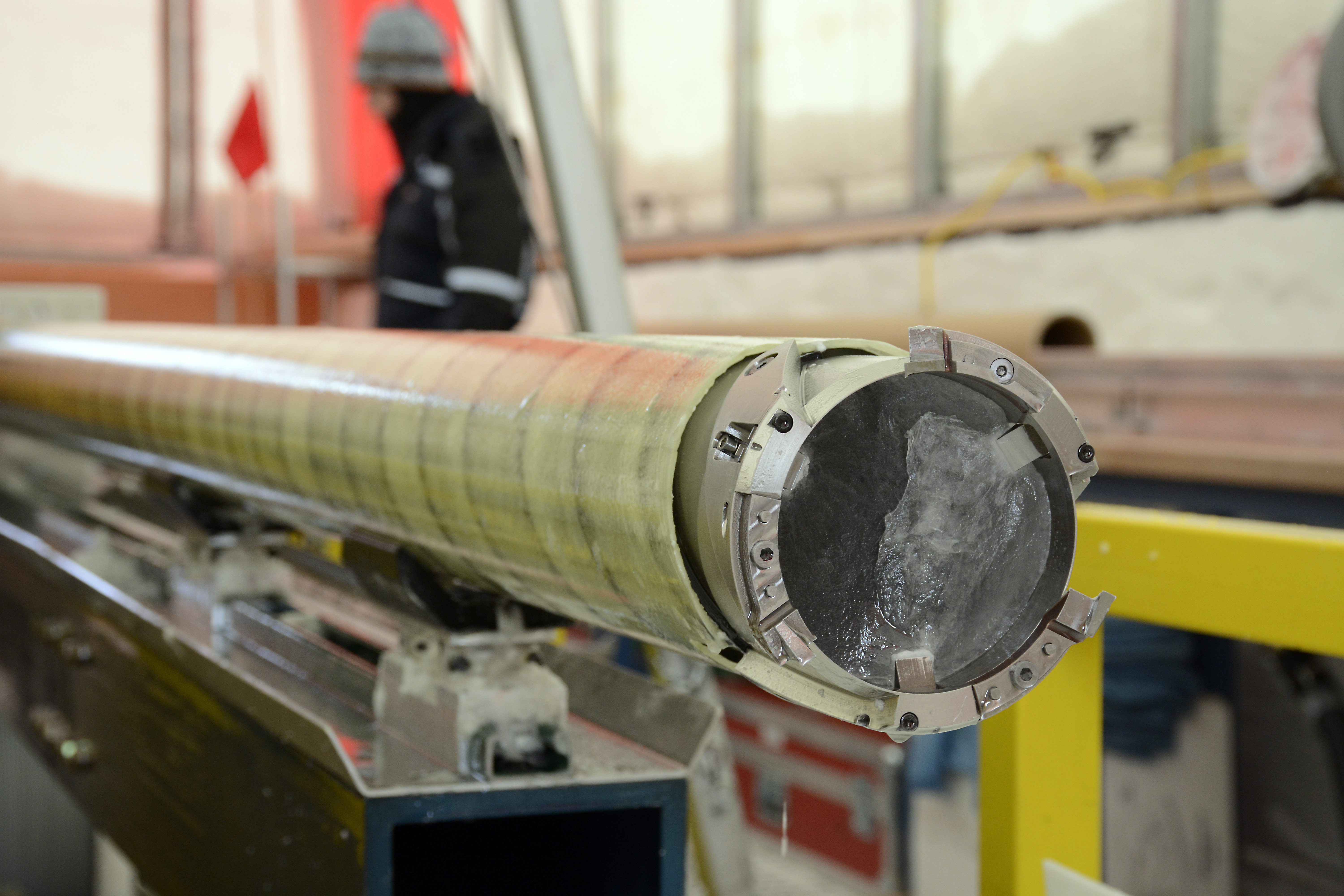

The drill head of the Intermediate Depth Drill with a core inside the drill barrel. The rotating drill head contains three razor sharp cutters that shave out an annulus of ice, which the drill then slides down into. As the drill slides down into the annulus it slides over the core, which is 98 mm (3.86 inches) in diameter. When a cable pulls up the drill, three cams grab the core and break it free. After the drill is pulled back to the surface it is lowered from a vertical to horizontal orientation so that the ice core can be removed from the drill barrel. Credit: T.J. Fudge

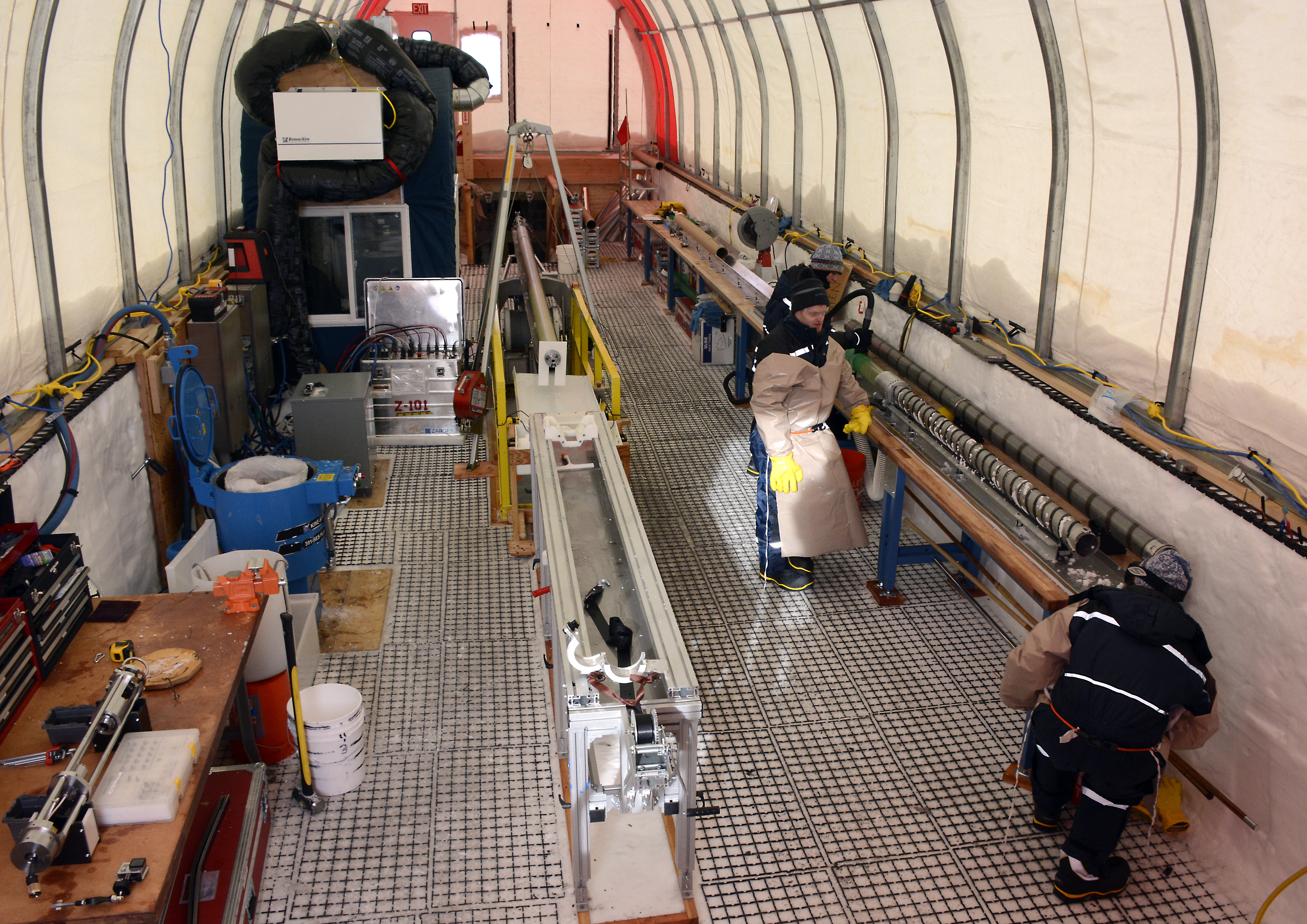

Science team members work in the South Pole Ice Core drill tent, cleaning the drill and measuring ice cores. Credit: Peter Rejcek

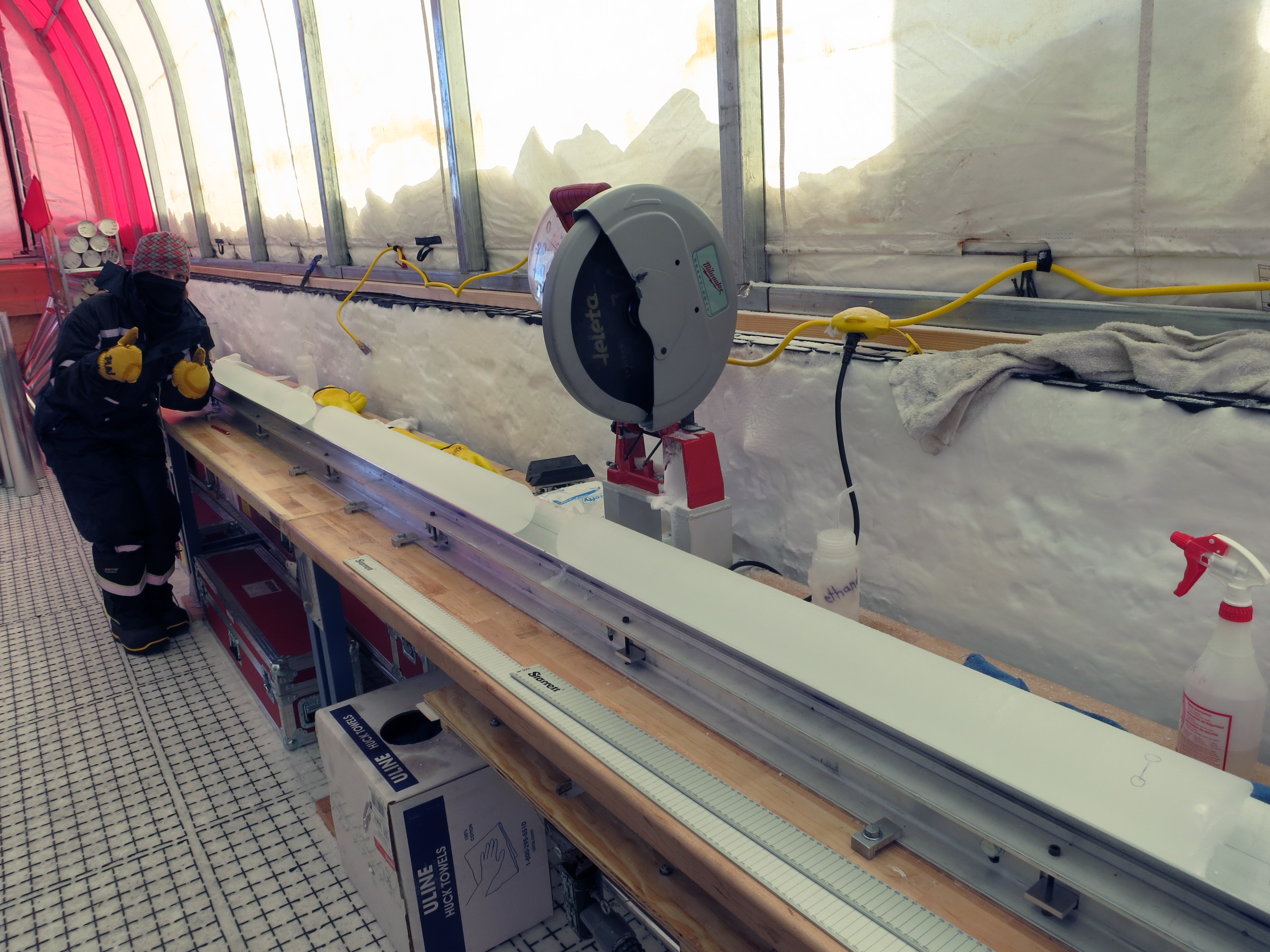

Mindy Nicewonger at the core processing station inside the drill tent for the South Pole Ice Core project. The IDD recovers ice cores approximately 2-meters in length. The 2-meter long sections of core are then cut into 1-meter long sections so that they fit into the standard-sized insulated shipping container (ISC) boxes used by the US ice-coring community to transport ice cores. A dry-cut circular saw is used to make the cuts. Credit: Murat Aydin

Moving ice cores up out of the South Pole Ice Core project's core storage trench to ready them for transport to McMurdo Station. Credit: Jay Johnson

View of the inside of the South Pole Ice Core project's core storage trench after all of the 2-meter-long sections of brittle ice were cut into 1-meter-long sections and packed into the white ISC boxes. Credit: Joseph Souney

Cutting the 2-meter long sections of brittle ice into 1-meter long sections during the 2015-2016 summer field season of the South Pole Ice Core project. Credit: Jay Johnson