The Winkie Drill is a commercially-available rock coring system originally purchased by IDP in 2015. IDP has implemented upgrades to add ice augering and ice coring capabilities. The system has a depth capability of 120 meters and creates ice and rock cores 33.4 mm (1.3-inch) in diameter. Modifications were subsequently made to accommodate a request for larger core diameter (71.7 mm) as well as replacement of the gas engine with an electric motor, for improved reliability and to allow for operation inside a tent. In 2018, IDP engineers incorporated modifications for use of the drill in areas where surface firn covers the ice and bedrock below. In 2020 and 2021, IDP built a second Winkie Drill, referred to as Winkie 2, to meet funded field project demands. A new fluid chiller was designed and fabricated to mitigate warm temperatures and drilling challenges, and a slip-style foot clamp assembly was also implemented recently to improve safety when tripping drill rod and casing into and out of the borehole. In 2023, an electronic pressure relief valve (PRV) was implemented to reduce the potential for a hydro fracture event while drilling through ice, and new core barrels and bits with greater clearances were implemented to help with cuttings and fluid transport in mixed media and clay.

Both Winkie Drills are deployed regularly to the Arctic and Antarctic. An Eclipse Drill is currently sent with each system to drill pilot holes.

The Winkie Drill is one of two rock coring drills in the IDP inventory (see also ASIG Drill).

Equipment Details

| Name | Winkie Drill |

|---|---|

| Type |

Type

Rock Coring; Ice Coring/Augering

|

| Number in Inventory |

Number in Inventory

2

|

| Max. Practical Depth |

Max. Practical Depth

120 m using standard AW34 drill rod. Designed as a rock drill so should also be possible with enough time and fluid to drill 120 m of rock core.

|

| Hole Diameter |

Hole Diameter

50 - 52 mm (augering)

86 mm

|

| Ice Core Diameter |

Ice Core Diameter

33.4 mm

71.7 mm

|

| Ice Core Length |

Ice Core Length

1.5 m

|

| Rock Core Diameter |

Rock Core Diameter

33.4 mm

|

| Rock Core Length |

Rock Core Length

1.5 m

|

| IDP Driller Required? |

IDP Driller Required?

Yes, 1 driller (2 people required for drill operation)

|

| Drill Fluid Required? |

Drill Fluid Required?

Yes

|

| Trench Required? |

Trench Required?

No |

| Power Requirements/Source |

Power Requirements/Source

Generator 2.5 kW

|

| Estimated Drilling Time |

Estimated Drilling Time

Augering Ice: 0.4-0.5 m/min rate of penetration |

| Time to Move (breakdown and setup) |

Time to Move (breakdown and setup)

3 hours (set up time)

|

| Helicopter Transportable? |

Helicopter Transportable?

Yes

|

| Light Aircraft Transportable? |

Light Aircraft Transportable?

Yes

|

| Shipping Weight |

Shipping Weight

6,800 lbs (120 m) |

| Shipping Volume (Cube) |

Shipping Cube

110 |

| Restrictions |

Restrictions

In light of use of a drilling fluid, it is critical to select sites where the ice is frozen to the bedrock and is free of cracks and/or the presence of liquid water. Any voids within the ice or near the bed will result in a pressure drop and loss of fluid flow and would halt drilling. In addition, site selection should favor areas where the bed geometry and ice flow minimize pre-existing stresses present in the ice, reducing the risk of hydro fracture during drilling. |

Documents

| Citation | Year |

|---|---|

| Joanne S Johnson, John Woodward, Ian Nesbitt, Kate Winter, Seth Campbell, Keir Nichols, Ryan Venturelli, Scott Braddock, Brent Goehring, Brenda Hall, Dylan H Rood, Greg Balco (2025) Assessing the suitability of sites near Pine Island Glacier for subglacial bedrock drilling aimed at detecting Holocene retreat–readvance. The Cryosphere, 19, 303-324. doi: 10.5194/tc-19-303-2025. https://doi.org/10.5194/tc-19-303-2025 | 2025 |

| Mary R Albert, Kristina R Slawny, Jay A Johnson, Elliot Moravec, Tanner W Kuhl (2024) Drilling Ice and Subglacial Rock Cores for Scientific Discovery in a Changing Climate. In: Glaciers - Recent Research, Importance to Humanity and the Effects of Climate Change. IntechOpen. Edited by Emeritus Prof. Stuart Arthur Harris, doi: 10.5772/intechopen.1004695. https://doi.org/10.5772/intechopen.1004695 | 2024 |

| Scott Braddock, Ryan Venturelli, Keir Nichols, Elliot Moravec, Grant Boeckmann, Seth Campbell, Greg Balco, Robert Ackert, David Small, Joanne S Johnson, Nelia Dunbar, John Woodward, Sujoy Mukhopadhyay, Brent Goehring (2024) Lessons learned from shallow subglacial bedrock drilling campaigns in Antarctica. Annals of Glaciology, 1-11. doi: 10.1017/aog.2024.12. https://doi.org/10.1017/aog.2024.12 | 2024 |

| NSF Ice Drilling Program (2024) Winkie Drill Operations and Maintenance Manual. 1-47. | 2024 |

| Grant Boeckmann, Chris J Gibson, Tanner W Kuhl, Elliot Moravec, Jay A Johnson, Zachary Meulemans, Kristina R Slawny (2021) Adaptation of the Winkie Drill for subglacial bedrock sampling. Annals of Glaciology, 62, (84), 109-117. doi: 10.1017/aog.2020.73. https://doi.org/10.1017/aog.2020.73 | 2021 |

| Mary R Albert, Kristina R Slawny, Grant Boeckmann, Chris J Gibson, Jay A Johnson, Keith Makinson, Julius Rix (2020) Recent Innovations in Drilling in Ice. Chapter 6 of Advances in Terrestrial Drilling: Ground, Ice and Underwater, Bar-Cohen and Zacny, eds., 157-220. https://www.routledge.com/Advances-in-Terrestrial-Drilling-Ground-Ice-and-Under… | 2020 |

| Allie Balter, Lucas H Beem, John W Goodge, Sean Gulick, Chloe Gustafson, David Harwood, Jennifer Lamp, Amy Leventer, Amelia Schevenell, Matthew R Siegfried, Perry Spector, John Stone, Slawek Tulaczyk, Sophie Warny, Paul Winberry, Dale Winebrenner, Duncan Young (2019) Assessment of East Antarctic Ice Sheet sensitivity to warming and its potential for contributions to sea level rise. Ice Drilling Program Subglacial Access Working Group Science Planning Workshop, March 29-30, 2019, Herndon, Virginia, USA, 1-18. | 2019 |

| Kristin Poinar, Jennifer Lamp, Allie Balter, Perry Spector, Dale Winebrenner, Slawek Tulaczyk (2019) Subglacial Access Working Group (SAWG): Access Drilling Priorities in Greenland. Ice Drilling Program Subglacial Access Working Group Science Planning Workshop, March 29-30, 2019, Herndon, Virginia, USA, 1-7. | 2019 |

| Perry Spector, John Stone, Nathaniel Lifton, Robert Ackert, Brent Goehring, Greg Balco, Bill McIntosh, Seth Campbell, Matt Zimmerer, Trista J Vick-Majors, Dale Winebrenner (2019) Drilling priorities to determine the past extent of the Antarctic Ice Sheet. Ice Drilling Program Subglacial Access Working Group Science Planning Workshop, March 29-30, 2019, Herndon, Virginia, USA, 1-10. | 2019 |

Photos

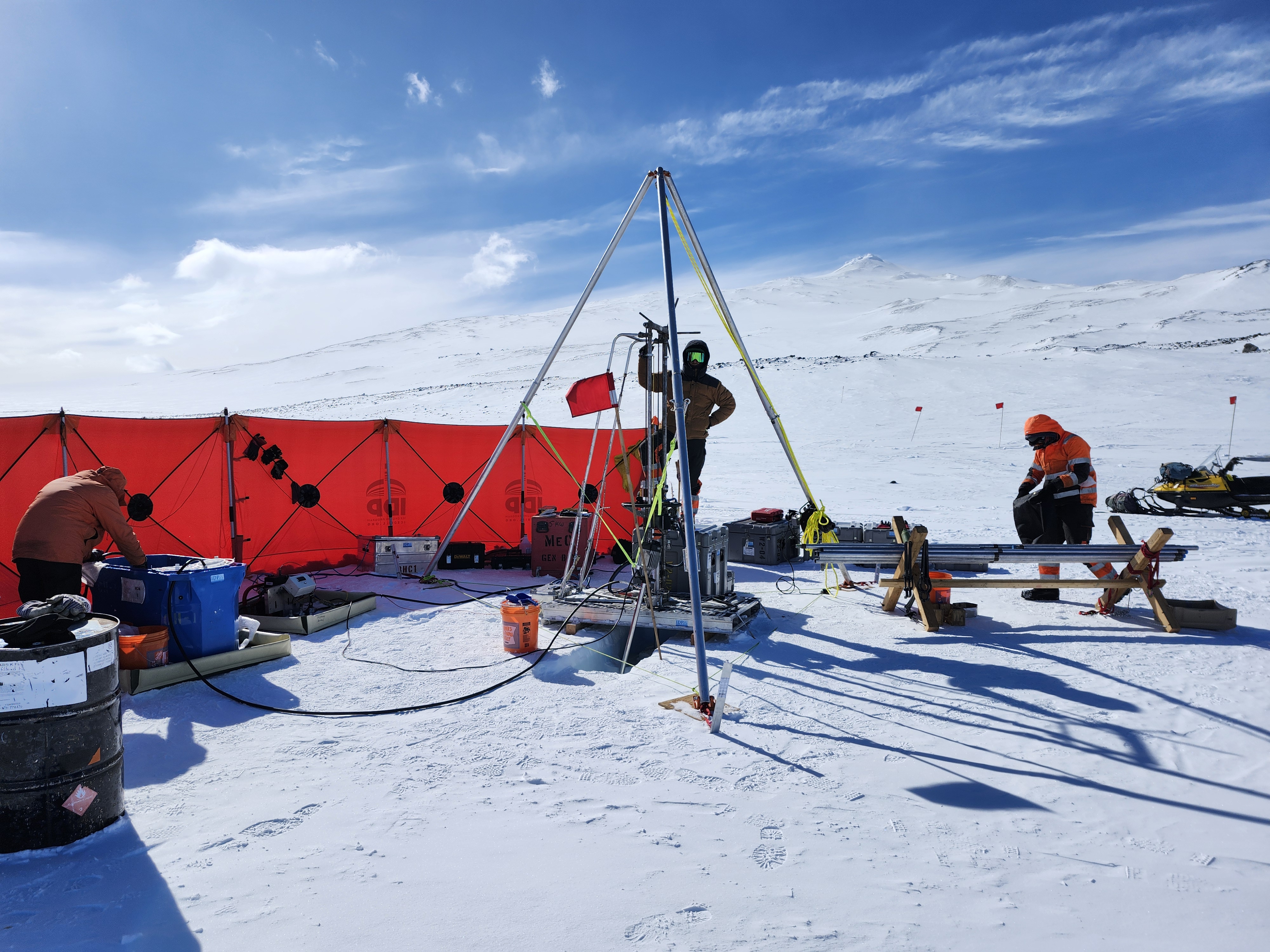

IDP Winkie Drill operations in the inflatable Axion tent in NE Greenland in support of the GreenDrill project during the 2024 field season. Credit: Allie Balter-Kennedy.

A subglacial porous lava bedrock core recovered with the Winkie Drill at Mount Waesche, Antarctica, during the 2024/25 field season. Credit: Elliot Moravec.

IDP Driller Rubin Harmon operates the Winkie Drill in windy conditions in northwest Greenland during the 2023 field season for the GreenDrill project. Credit: Jason Briner.

IDP engineer and driller, Elliot Moravec, works with one of the drill bits for the Winkie Drill during the 2023 GreenDrill field season. Credit: Jason Briner.

A mixed media core consisting of ice, silt and rock from Ong Valley, Antarctica. Credit: Grant Boeckmann

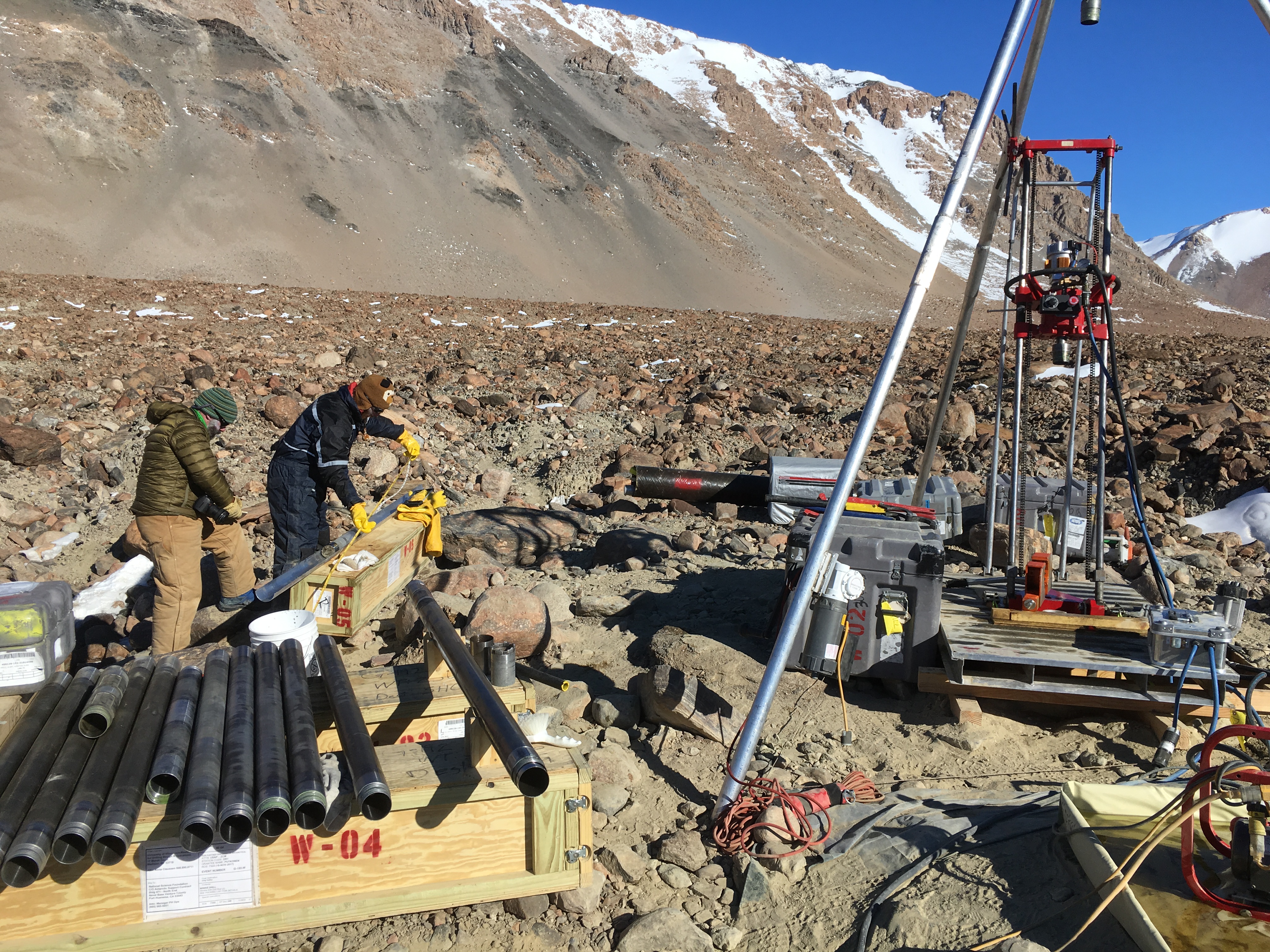

The Winkie Drill in Ong Valley, Antarctica, during the 2017-2018 Antarctic field season. Credit: Andrew Grant

The Winkie Drill in Ong Valley, Antarctica, during the 2017-2018 Antarctic field season. Credit: Grant Boeckmann