The Deep Ice Sheet Coring (DISC) Drill is a tilting-tower electromechanical drill designed to take 122 mm (4.8-inch) diameter ice cores to a depth of 4,000 m. The drill recovers cores up to 3.5 m long per run. To maintain field operations, the system includes a surface-based mechanical and electrical maintenance and repair shop built in a Mobile Expandable Container Configuration (MECC) ISO container. The drill was utilized for six production seasons at WAIS Divide, Antarctica, from 2007-2013 and completed the deepest U.S. ice core ever drilled at 3405 m depth. Replicate coring operations were also successfully completed onsite (see Replicate Coring System). In PY 2015, IDP worked with community scientists to complete revised science requirements for the DISC Drill. This iterative process included discussion of the feasibility of reducing the drill’s logistical footprint.

Current Status

Decommissioning in progress.

In spring 2020, all remaining DISC Drill components were returned to Madison. In 2017, IDP worked with science community representatives to complete a DISC Drill vs. Foro 3000 (see Foro 3000 section) analysis, to help determine which system should be used for the next deep U.S. ice drilling project at Hercules Dome, Antarctica. The community consensus was that IDP should pursue development of the Foro 3000 Drill. As much of the functionality of this drill is being replaced by the new Foro 3000 Drill, IDP initiated a discussion with the science community in spring 2021 regarding decommissioning of the DISC Drill. A survey was also distributed to the science community in August 2021 to gauge interest in future use of the drill. Following these efforts and with the approval of the NSF, IDP will soon decommission the DISC Drill and remove it from inventory. The MECC (Mobile Expandable Container Configuration) machine shop would not be decommissioned as it is planned for use with the Foro 3000 Drill.

Equipment Details

| Name | Deep Ice Sheet Coring Drill |

|---|---|

| Type |

Type

Ice coring

|

| Number in Inventory |

Number in Inventory

1

|

| Max. Practical Depth |

Max. Practical Depth

4000 m

|

| Hole Diameter |

Hole Diameter

163 mm (thin kerf cutter head)

170 mm (original cutter head)

|

| Ice Core Diameter |

Ice Core Diameter

122 mm (4.8 inches)

|

| Ice Core Length |

Ice Core Length

3.2 m

|

| Rock Core Diameter |

Rock Core Diameter

[NA]

|

| Rock Core Length |

Rock Core Length

[NA]

|

| IDP Driller Required? |

IDP Driller Required?

Yes, 3+ (number of drillers required depends on desired drilling depth and drilling schedule)

|

| Drill Fluid Required? |

Drill Fluid Required?

Yes

|

| Trench Required? |

Trench Required?

Yes |

| Power Requirements/Source |

Power Requirements/Source

135 kW, 460 V 3-phase

|

| Helicopter Transportable? |

Helicopter Transportable?

No

|

| Light Aircraft Transportable? |

Light Aircraft Transportable?

No

|

| Shipping Weight |

Shipping Weight

~136,000 lbs (~61,700 kg) |

| Shipping Volume (Cube) |

Shipping Cube

8,500 |

Documents

| Citation | Year |

|---|---|

| Pavel Talalay, Hong J (2021) Perspectives for development of ice drilling technology: continuation of the discussion. Annals of Glaciology, 62, (84), 143-156. doi: 10.1017/aog.2020.81. https://doi.org/10.1017/aog.2020.81 | 2021 |

| Mary R Albert, Kristina R Slawny, Grant Boeckmann, Chris J Gibson, Jay A Johnson, Keith Makinson, Julius Rix (2020) Recent Innovations in Drilling in Ice. Chapter 6 of Advances in Terrestrial Drilling: Ground, Ice and Underwater, Bar-Cohen and Zacny, eds., 157-220. https://www.routledge.com/Advances-in-Terrestrial-Drilling-Ground-Ice-and-Under… | 2020 |

| Jay A Johnson, Matthew J Kippenhan (2017) DISC Drill vs. Foro 3000 Drill Analysis. 1-24. | 2017 |

| Chris J Gibson, Jay A Johnson, Alexander J Shturmakov, Nicolai B Mortensen, Joshua J Goetz (2014) Replicate ice-coring system architecture: mechanical design. Annals of Glaciology, 55, (68), 165-172. doi: 10.3189/2014AoG68A019. https://doi.org/10.3189/2014AoG68A019 | 2014 |

| Jay A Johnson, Nicolai B Mortensen, Chris J Gibson, Joshua J Goetz, Alexander J Shturmakov (2014) Replicate ice-coring system testing. Annals of Glaciology, 55, (68), 331-338. doi: 10.3189/2014AoG68A034. https://doi.org/10.3189/2014AoG68A034 | 2014 |

| Nicolai B Mortensen, Jay A Johnson, Alexander J Shturmakov (2014) Precision cable winch level wind for deep ice-coring systems. Annals of Glaciology, 55, (68), 99-104. doi: 10.3189/2014AoG68A013. https://doi.org/10.3189/2014AoG68A013 | 2014 |

| Nicolai B Mortensen, Joshua J Goetz, Chris J Gibson, Jay A Johnson, Alexander J Shturmakov (2014) Replicate ice-coring system architecture: electrical, electronic and software design. Annals of Glaciology, 55, (68), 156-164. doi: 10.3189/2014AoG68A014. https://doi.org/10.3189/2014AoG68A014 | 2014 |

| Alexander J Shturmakov, Donald A Lebar, Charles R Bentley (2014) DISC drill and replicate coring system: a new era in deep ice drilling engineering. Annals of Glaciology, 55, (68), 189-198. doi: 10.3189/2014AoG68A017. https://doi.org/10.3189/2014AoG68A017 | 2014 |

| Kristina R Slawny, Jay A Johnson, Nicolai B Mortensen, Chris J Gibson, Joshua J Goetz, Alexander J Shturmakov, Donald A Lebar, Anthony W Wendricks (2014) Production drilling at WAIS Divide. Annals of Glaciology, 55, (68), 147-155. doi: 10.3189/2014AoG68A018. https://doi.org/10.3189/2014AoG68A018 | 2014 |

| Joseph M Souney, Mark S Twickler, Geoffrey M Hargreaves, Brian M Bencivengo, Matthew J Kippenhan, Jay A Johnson, Eric D Cravens, Peter D Neff, Richard M Nunn, Anais J Orsi, Trevor J Popp, John F Rhoades, Bruce H Vaughn, Donald E Voigt, Gifford J Wong, Kendrick C Taylor (2014) Core handling and processing for the WAIS Divide ice-core project. Annals of Glaciology, 55, (68), 15-26. doi: 10.3189/2014AoG68A008. https://doi.org/10.3189/2014AoG68A008 | 2014 |

Photos

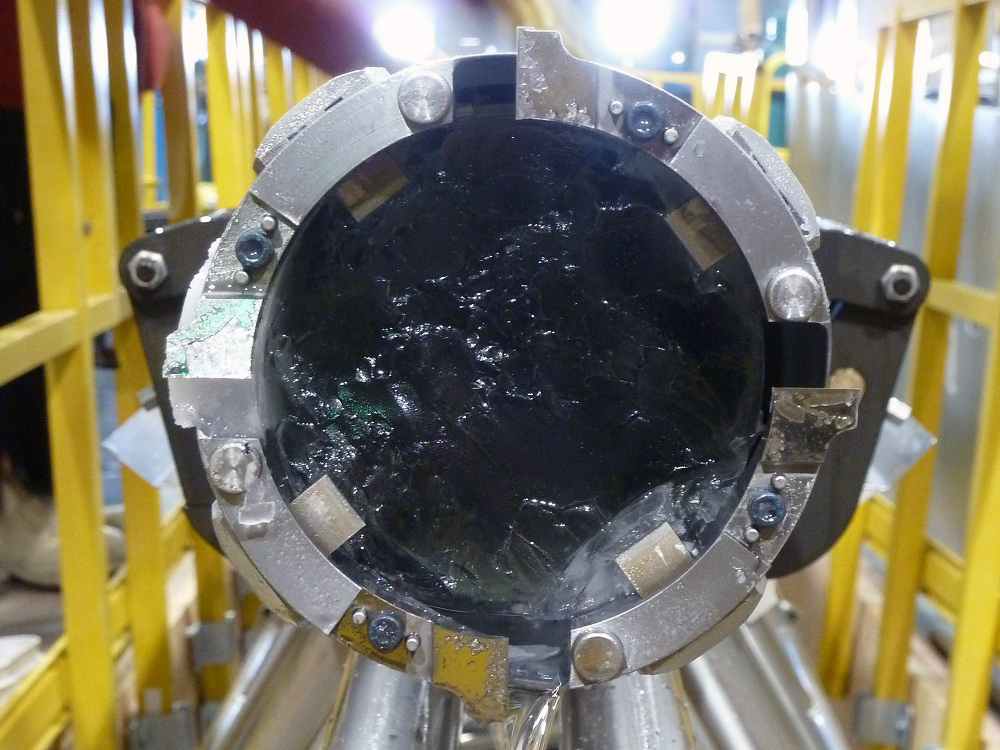

The drill head of the DISC Drill with a core inside the drill barrel. The rotating drill head contains four razor sharp cutters that shave out an annulus of ice, which the drill then slides down into. As the drill slides down into the annulus it slides over the core, which is 122 mm (4.8 inches) in diameter and 2.7 meters long. When a cable pulls up the drill, four cams grab the core and break it free. After the drill is pulled back to the surface it is lowered from a vertical to horizontal orientation so that the ice core can be removed from the drill barrel. Credit: Jay Johnson