For the first time, significant innovations in ice drilling engineering are providing scientists with replicate ice cores from targeted depths and directions in the ice sheet!

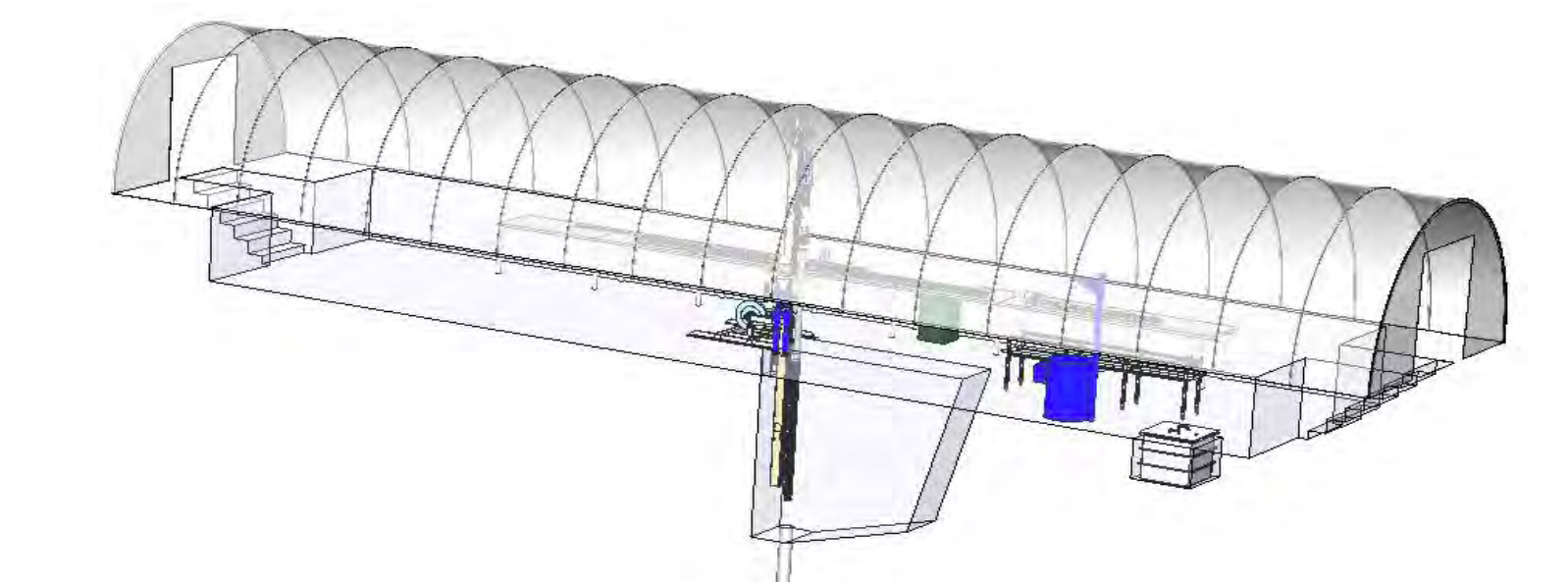

The newly developed, state-of-the-art Replicate Ice Coring System was deployed in December 2012 to re-enter the 6.5-inch diameter deep borehole at WAIS Divide, Antarctica, and successfully allowed the researchers to drill through the wall of the 3,405 meter deep parent borehole and collect a total of 285 meters of additional core from five of the most interesting time periods in the WAIS Divide climate record.

The Replicate Ice Coring System is capable of retrieving additional ice cores from specific depths on the uphill side of the main (parent) borehole. The Replicate Coring technique, developed and tested by the IDDO engineers as part of the Deep Ice Sheet Coring (DISC) Drill, is a key advance, because it allows scientists to take samples from specific levels of a parent borehole without impeding the hole itself, leaving the parent borehole open for future logging of information.

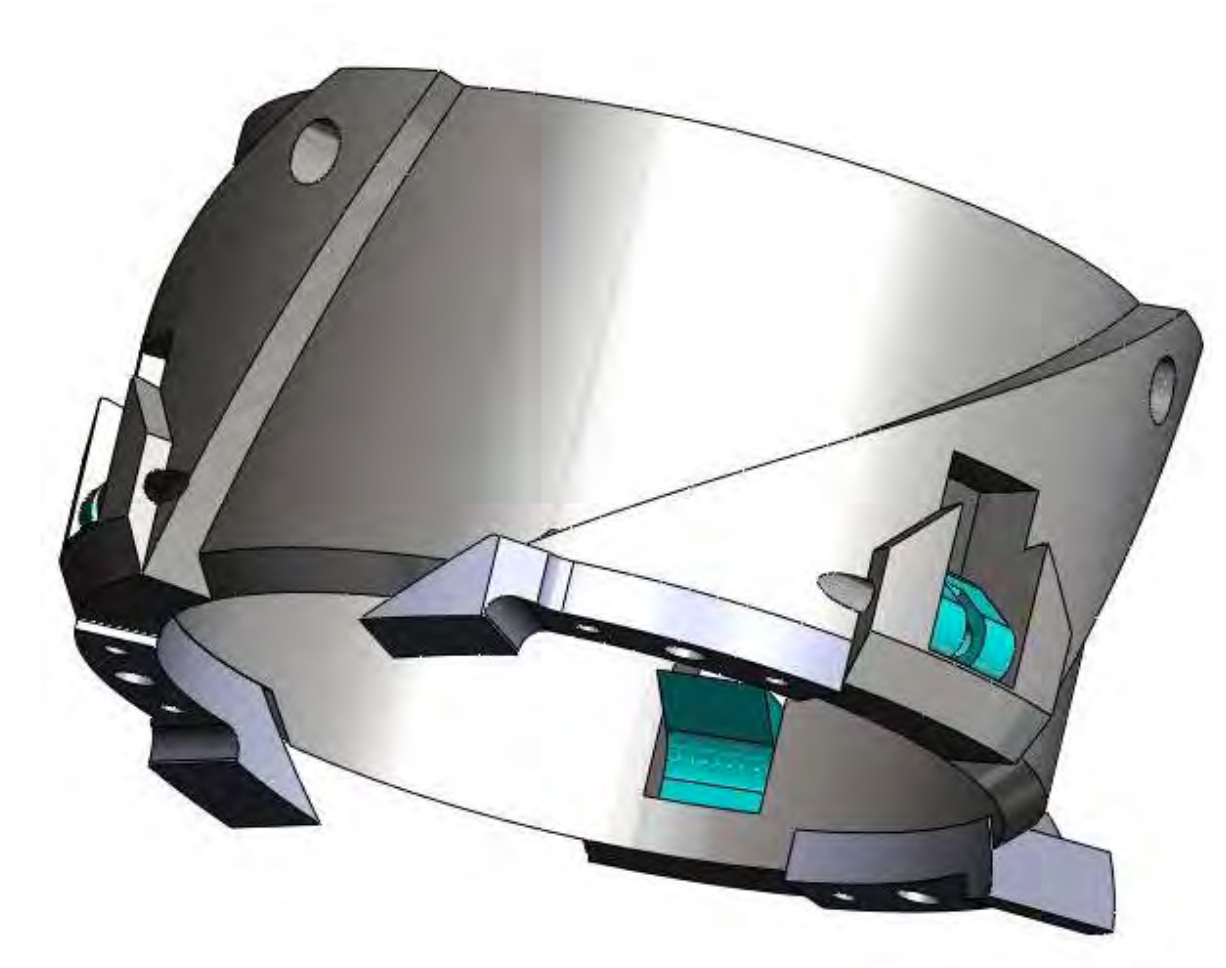

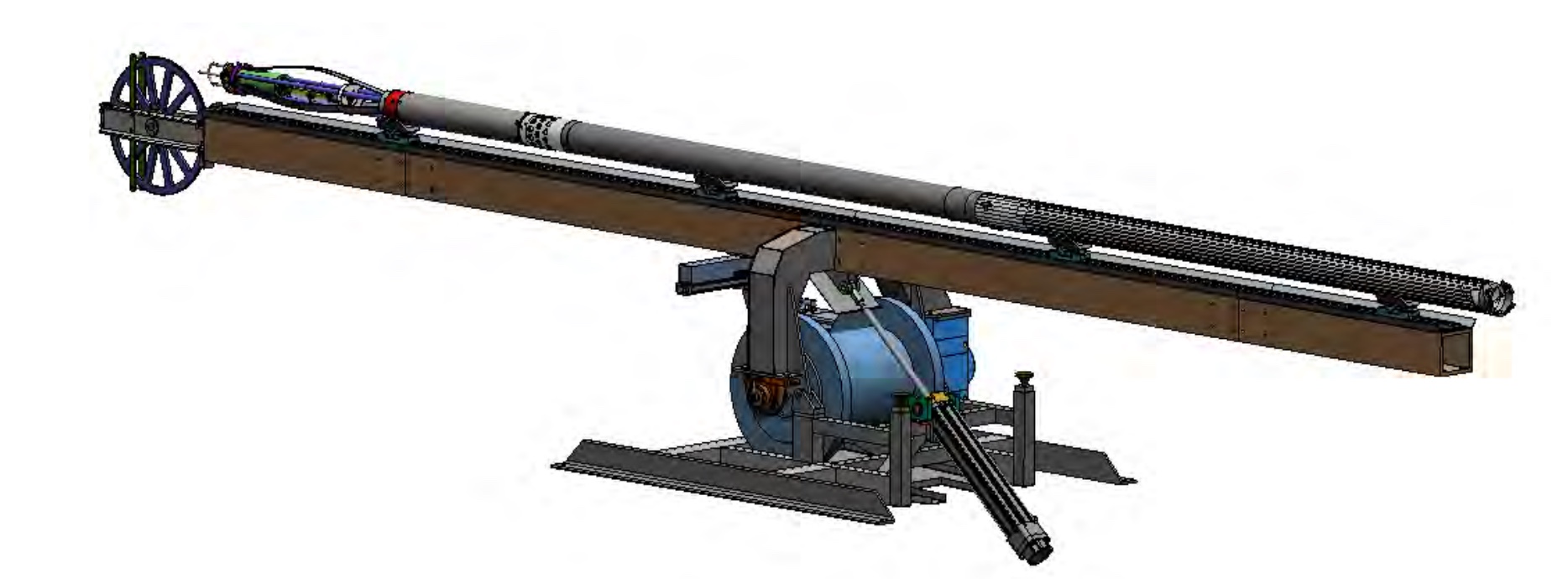

The Replicate Ice Coring System collects additional ice at depths of interest by deploying into an existing borehole and then deviating from it. The drill uses two steering actuator sections to tilt itself in the parent borehole by applying sidewards force against the borehole wall. In the first step of the process, the broaching cutter head is deployed to the target depth. Using the actuators, the drill is tipped to the high ("up hill") side of the borehole to engage the cutters. Ice is removed in repeated passes of approximately 15 meters in the up-stroke. In the second step of the process, a milling head is deployed and creates a landing for the coring head. In the third step of the process, a coring head removes a 20 mm kerf and allows a 108 mm diameter core to enter the core barrel. Two meters of core are removed per trip. The coring is repeated until all of the desired replicate ice from the target depth is obtained.

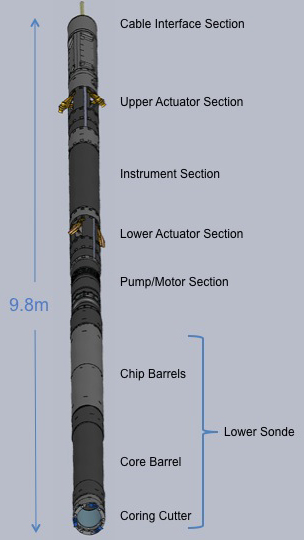

The Replicate Ice Coring System builds on the existing infrastructure of the DISC Drill and thus requires substantial logistics and infrastructure support. However, the design and engineering behind the system is such that it can be scaled down for use with smaller, more agile drilling systems as well. The downhole portion of the DISC Drill, the sonde, was significantly modified to meet the requirements of steering out of the parent hole. The major components of the replicate sonde are described below.

Cable Interface Section

The existing cable interface section of the DISC Drill provides the connection to 4km of fiber optic cable.

Upper Actuator Section

The upper actuator section steers the drill, and with the anti-torque levels extended keeps the drill from spinning during cutting operations.

Instrument Section

The instrument section provides power and communications to operate the drill.

Lower Actuator Section

The lower actuator is identical to the upper actuator, but is configured with discs on the levers to provide smooth navigation.

Pump/Motor Section

The pump/motor section has a powerful pump for chip transport and contains the cutter motor.

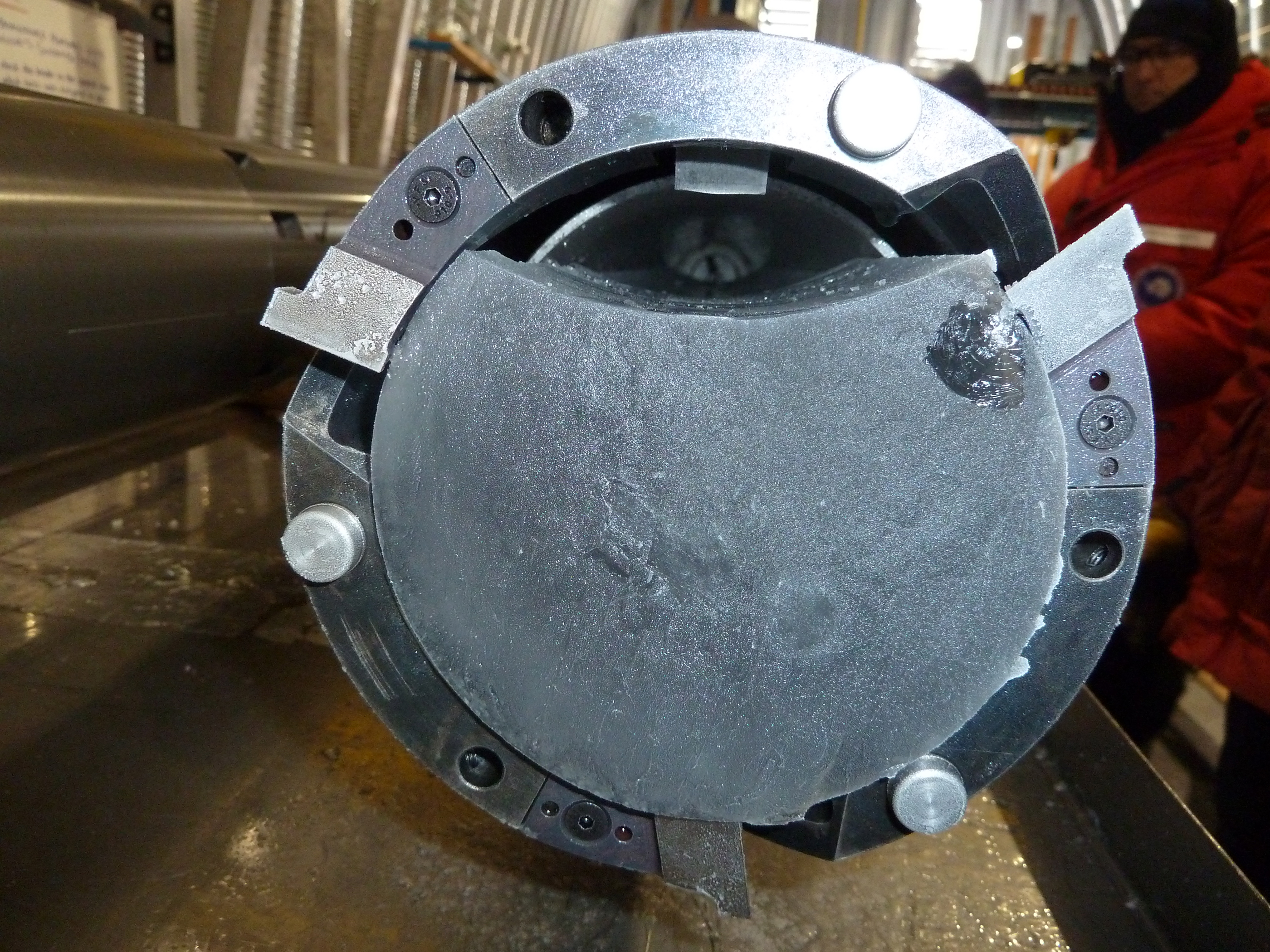

Lower Sonde

The lower sonde includes chip barrels that collect the chips that are cut during coring, a core barrel to collect the core, and the coring head. The lower sonde can be assembled in multiple configurations to meet the needs of the different stages of the replicate coring process.