IDDO Receives Minerals Exploration Rig; Enters Exciting New Avenue of Subglacial Rock Coring

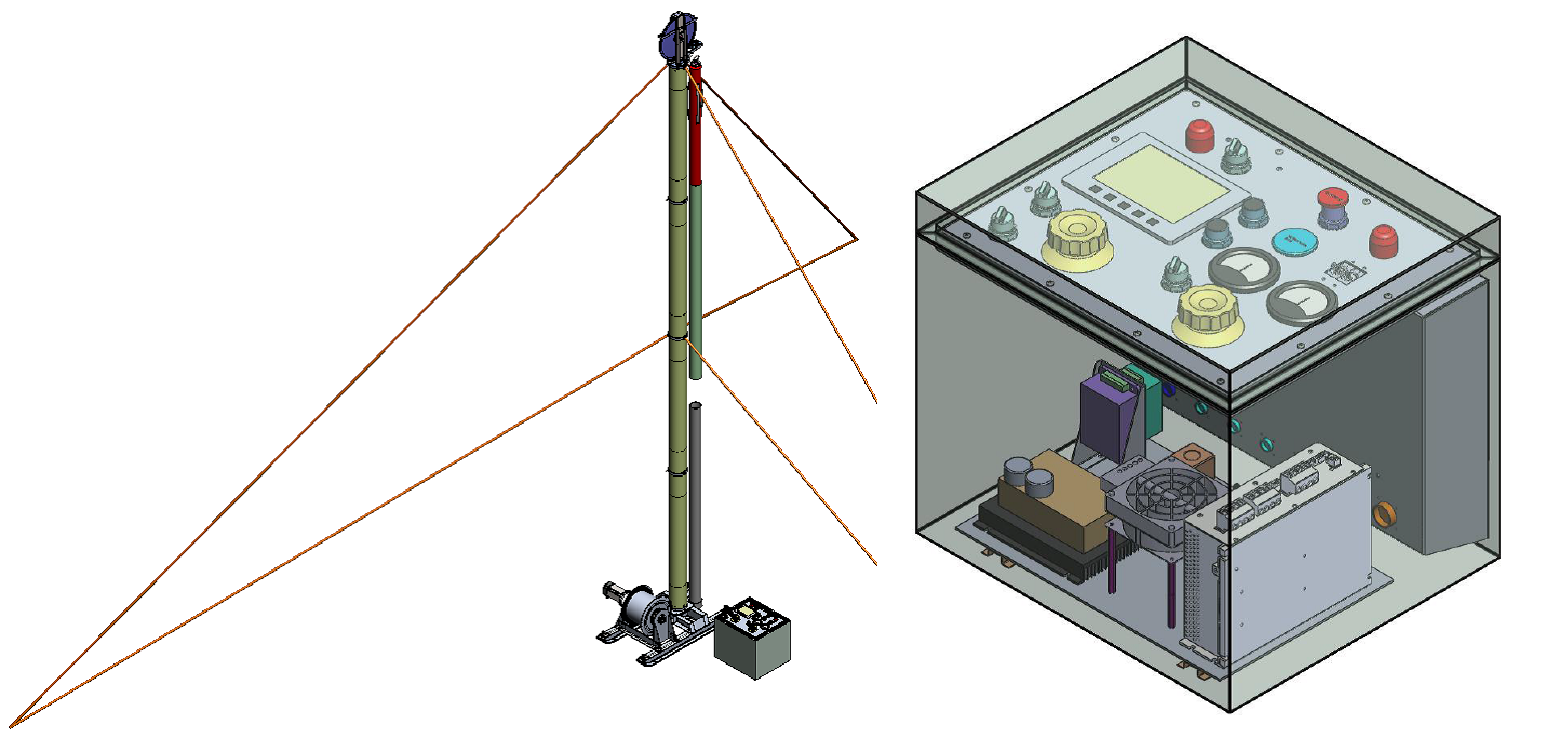

- Agile Sub-Ice Geological Drill

On April 13, 2015, IDDO received a new minerals exploration drill rig, purchased from Multi-Power Products Ltd. in British Columbia, Canada. This base rig will serve as the primary component in IDDO's development of the new Agile Sub-Ice Geological (ASIG) Drill system. The relatively compact system will be able to drill access holes through ice less than 700 m thick and subsequently collect bedrock cores from beneath glaciers. IDDO engineers, led by Project Manager and IDDO Lead Mechanical Engineer Chris Gibson, are now designing and fabricating auxiliary systems such as ice coring attachments and fluid and ice chip handling and filtration systems to complement the base rock coring drill for use in the polar regions. The ASIG Drill system will be built-up over the next year, with its first deployment to Antarctica expected in September 2016. Receipt of this rig marks entry into an exciting new avenue of drilling for IDDO, whose previous work has primarily focused on drilling ice cores and creating access holes in ice.

After its first use in Antarctica during the 2016-17 field season, the ASIG Drill system is expected to be available again for community use beginning in ~September 2017. For more information about using the ASIG Drill, contact IDPO-IDDO at IceDrill@Dartmouth.edu .

Greenland Firn Aquifer Project Battles Tremendous Snowfall

- Thermal Drill

- Fieldwork

In late March, IDDO engineer Josh Goetz deployed with the Greenland Firn Aquifer project science team (Forster, PI) to Kulusuk in Southeast (SE) Greenland. After issues with poor weather and with helicopter availability, the team made it into the icecap in SE Greenland and drilled the first of four planned holes into the firn aquifer layer using the Electrothermal Drill. A thermistor string was placed in the borehole, and while the plan was to then move to a second site, an unusually heavy pair of storms descended upon the camp, dropping approximately 2.5 meters of snow in just five days, precluding movement to the second site. Shown in the photo below, snow has completely covered the drill winch and nearly half of the 3.2 meter tall drill tower. It is surmised that the first storm encountered was the remnant of a hurricane that formed off the coast of Newfoundland.

IDDO Continues Collaboration with UW PSL Hot Water Drilling Experts to Make User-Identified Upgrades to Small Hot Water Drills

- Small Hot Water Drill

During PY 2014, IDDO worked with hot water drilling colleagues at the University of Wisconsin Physical Sciences Lab (PSL) to develop maintenance and upgrade plans for IDDO's aging Small Hot Water Drill (HWD) systems. The engineers at PSL were heavily involved with the design and operation of the very successful Enhanced Hot Water Drill for the IceCube project as well as the Askaryan Radio Array (ARA) Hot Water Drill for the more recent ARA project at the South Pole Station. Throughout PY 2015 and PY 2016, IDDO plans to work with the PSL engineers to specify and purchase many new components for the IDDO Small HWDs based on user feedback, as almost exclusively the PIs and their science teams operate these drills. During the Second Quarter, IDPO-Dartmouth organized a virtual meeting that enabled scientist-users of the drill an opportunity to see the planned upgrades and provide feedback to IDDO. The upgraded Small HWD, with a depth capability of 0-60 meters, will complement the planned Scalable Hot Water Drill, which is scalable in depth range from 60-1000 meters, depending upon individual project needs. Late in the quarter, assembly and testing of the existing Small HWD equipment was underway and IDDO plans to purchase upgraded components beginning in the Third Quarter.

Beneficial Design Upgrades Continue for 4-Inch 'Foro' Drill

- 4-Inch Drill

- Foro 400 Drill

During the Second Quarter, IDDO completed the preliminary design of the new 'Foro' Drill System to upgrade the popular, yet aging, 4-Inch Drill equipment. IDDO engineers have utilized feedback from 4-Inch Drill operators to make this new system lighter, more robust, more easily controlled, and more user-friendly. The sonde design is based on that of IDDO's Intermediate Depth Drill (IDD) and the current 4-Inch Drill designs, with certain components being interchangeable with the IDD, including the anti-torque section, motor section, and the cutter head. The designs for the 'Foro' Drill sled, winch, cable, and control system are brand new designs, and the tower is a modified and improved version of the current 4-Inch Drill tower design. The new sled, winch and tower assembly alone offer a 40% weight savings over the current 4-Inch Drill components. In addition, upgrading the control system to include only one comprehensive control/readout box, as opposed to the two separate boxes used by the 4-Inch Drill, will offer an additional 30% weight savings in this area. In March 2015, IDDO circulated a 'Name That Drill' Doodle poll to encourage IDPO and IDDO team members to vote on a name for the new components, so that distinguishing between the old and new equipment would be more straightforward. The name 'Foro' was selected, and is Latin for "to make a hole, pierce or to bore". On the last day of the Second Quarter, April 30th, IDDO held a Preliminary Design Review where the engineers presented the new system design and future plans for the 'Foro' Drill.

The major design upgrades for the 'Foro' Drill include:

- Redesign tower and winch to be lighter/smaller

- 5.7 mm diameter steel electromechanical winch cable, same as used on the IDD Drill (current 4-Inch Drill cable is 13mm in diameter)

- New cable weight is 13.1kg/100 m (current 4-Inch Drill cable weight is 17.1kg/100 m)

- Upgrades for wet conditions

- New sealed motor section – submersible in drilling fluid or water (current 4-Inch Drill is not submersible)

- Upgraded control system

- Drill and winch motors will be able to be run simultaneously

- Off-the-shelf motor controllers

- Reduced weight, compared to the existing 4-InchDrill control boxes

IDPO Advances School of Ice

- Education/ Outreach

- Meetings/ Workshops

The School of Ice is an advanced professional development workshop on ice core science for college faculty and high school teachers who teach advanced science courses. The initial cadre of participants has been selected from a highly competitive field of applicants. The twelve participants are professors from ten different states. Final preparations will continue for the event, which will occur in June 2015.

IDPO Leads Successful 2015 Science Advisory Board Meeting in Arlington, VA

- Long Range Plans

- Science Advisory Board

- Meetings/ Workshops

The IDPO Science Advisory Board (SAB) meeting was held on April 16-17, 2015 at the Hilton Arlington in Arlington, VA. Planning for the meeting was a joint effort by Mary Albert and SAB Chair Ed Brook. With participation of the entire SAB membership and attendance by seven NSF Program Managers as well as IDPO and IDDO management, the meeting was very productive in identifying the future direction of the science for the IDPO Long Range Science Plan and associated ice-drilling endeavors. Discussions also involved scenarios of possibilities for future hot water ice access drilling. The minutes and presentations from the meeting are available at https://icedrill.org/about/science-advisory-board.

Requesting Ice Drilling Support (2015 Spring)

- Fieldwork

If you are preparing a proposal that includes any kind of ice drilling or ice coring support from IDPO-IDDO, you must complete a Field Project Support Requirements Form (https://icedrill.org/requesting-field-support) and submit it to IDPO-IDDO via icedrill@dartmouth.edu at least six weeks before your proposal deadline. Once IDPO-IDDO receives your Field Project Support Requirements Form, we will provide you with a Letter of Support and Scope of Work/Cost Estimate document that MUST be included with your proposal. If you are submitting a proposal to NSF, the Letter of Support and Scope of Work/Cost Estimate document should be included as Supplemental Information in your proposal, and it is recommended that you also notify the relevant NSF Program Manager that your proposal requires support from IDPO-IDDO.

Drilling Support to Science Projects (2015 Spring)

- Fieldwork

Current – Arctic 2015

- Cosmogenic Carbon-14 in Polar Firn, Greenland (Petrenko)

- Disko Bay and Baffin Bay Firn and Ice Cores, Greenland (Das)

- Greenland Aquifer Investigation (Forster)

- Microbes and Ice Formation in Inland Waters, USA (McKay)

Upcoming – Antarctic 2015-2016

- Aerosol Fluxes to Taylor Dome/Glacier (Aciego)

- Carbon-14 from Taylor Glacier Blue Ice Cores (Petrenko)

- South Pole 1500-meter Ice Core (Aydin)

For the latest information on our current and upcoming field projects, visit:

https://icedrill.org/fieldwork