- Home

- Ice Bits Newsletter

Ice Bits Newsletter

Topics:

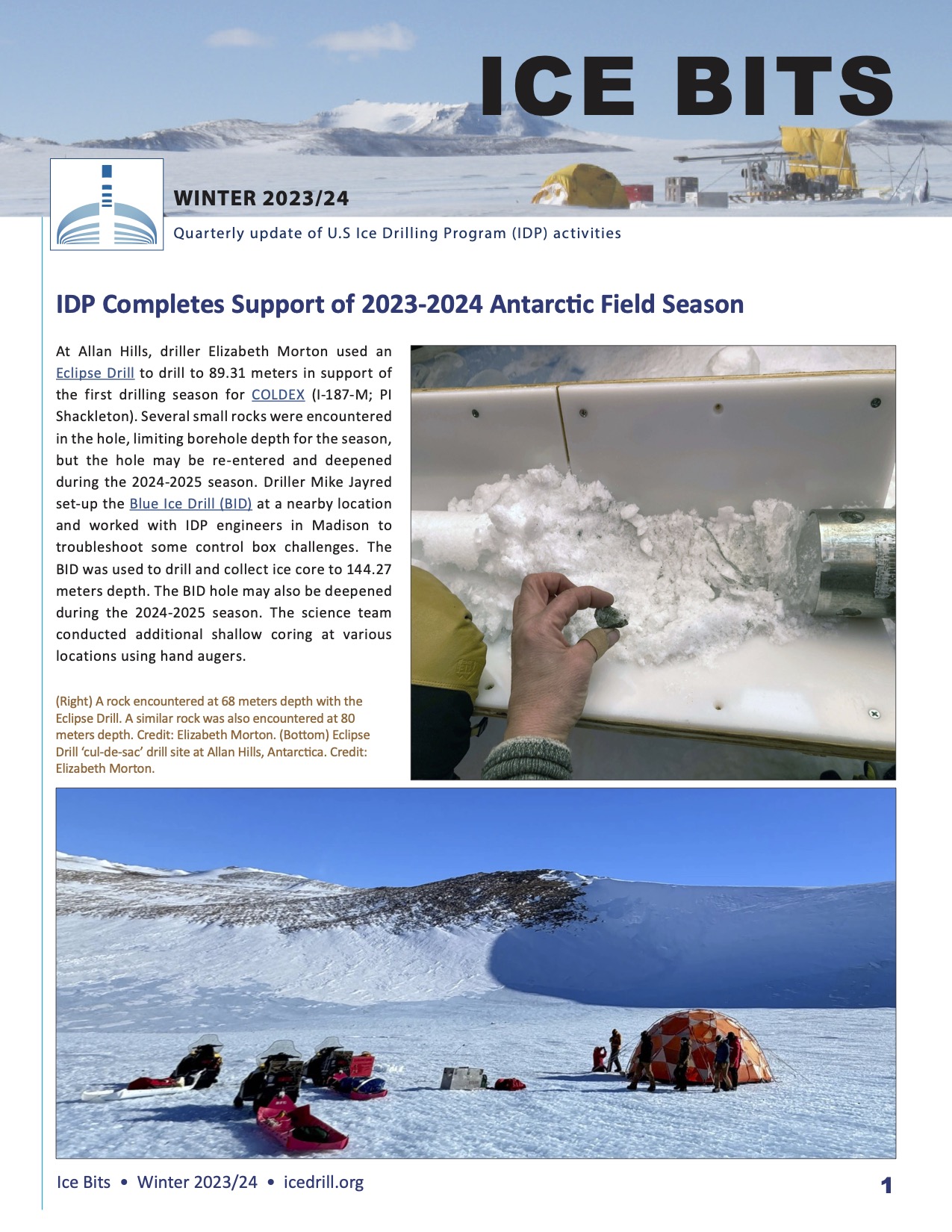

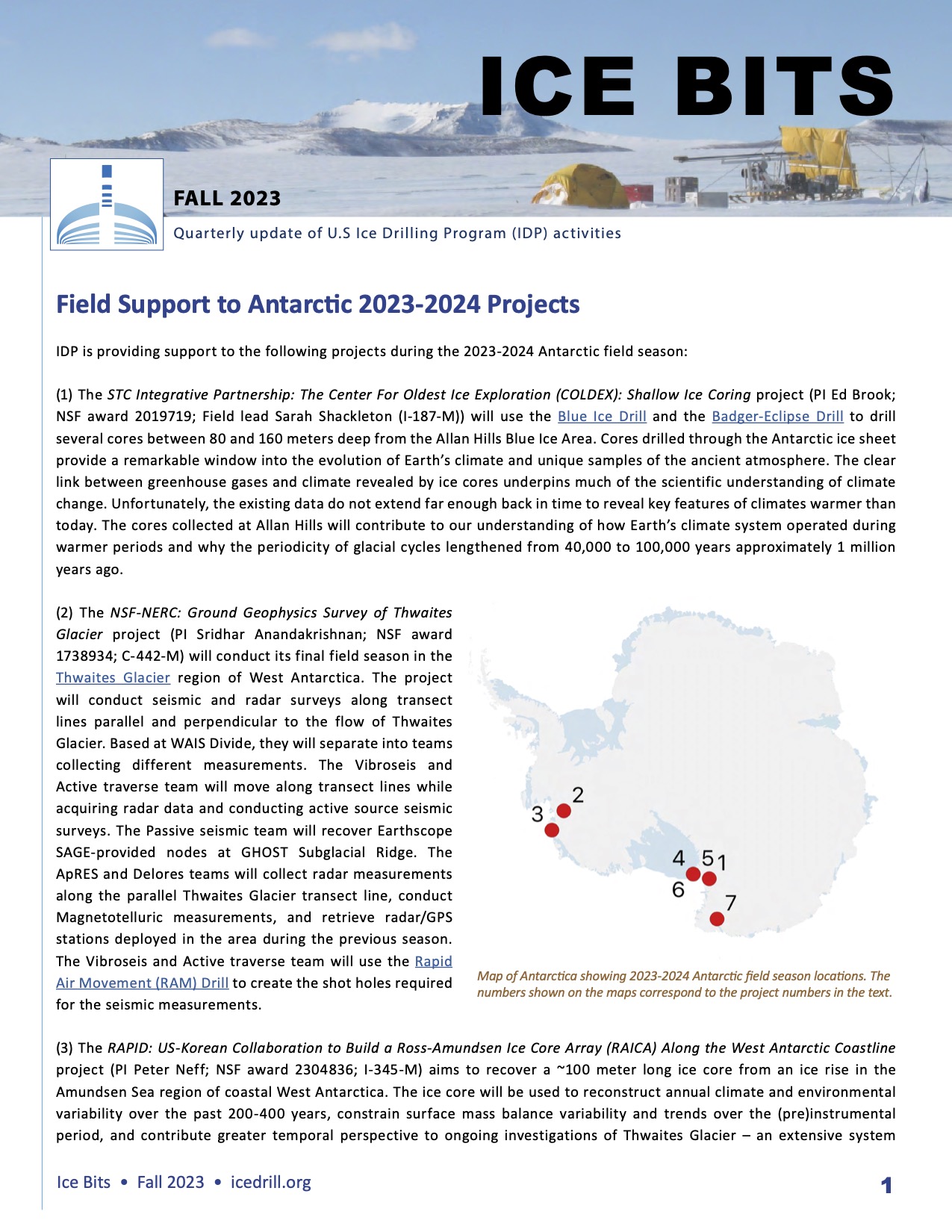

- IDP Completes Support of 2023-2024 Antarctic Field Season

- Drill Development and Maintenance/Upgrade News

- IDP Education and Public Outreach Workshops Increase Impact

- New Virtual Field Lab: Sea Level Rise and Thwaites Glacier: Vital Signs of the Doomsday Glacier

- IDP Hosts Successful Town Hall at 2023 AGU Fall Meeting

- Stay Connected with IDP

- Ice Drilling Support for NSF Polar Proposals

Topics:

- Field Support to Antarctic 2023-2024 Projects

- Drill Development and Maintenance/Upgrade News

- AGU Town Hall: Scientific Drilling in the Polar Regions

- Englacial and Subglacial Access Working Group (ESAWG)

- IDP at the 2023 AGU Fall Meeting

- New IDP Virtual Field Lab at AGU 2023 Fall Meeting

- Registration Now Open for Climate of HOPE Conference

- School of Ice Applications for COLDEX Workshop

- Collaboration Between Women Helps Close the Gender Gap in Ice Core Science

- Announcing 3rd US Ice Core Open Science Meeting

- ICECReW 1.5-day workshop before US Ice Core Open Science Meeting

- Stay Connected with IDP

- Ice Drilling Support for NSF Polar Proposals

Topics:

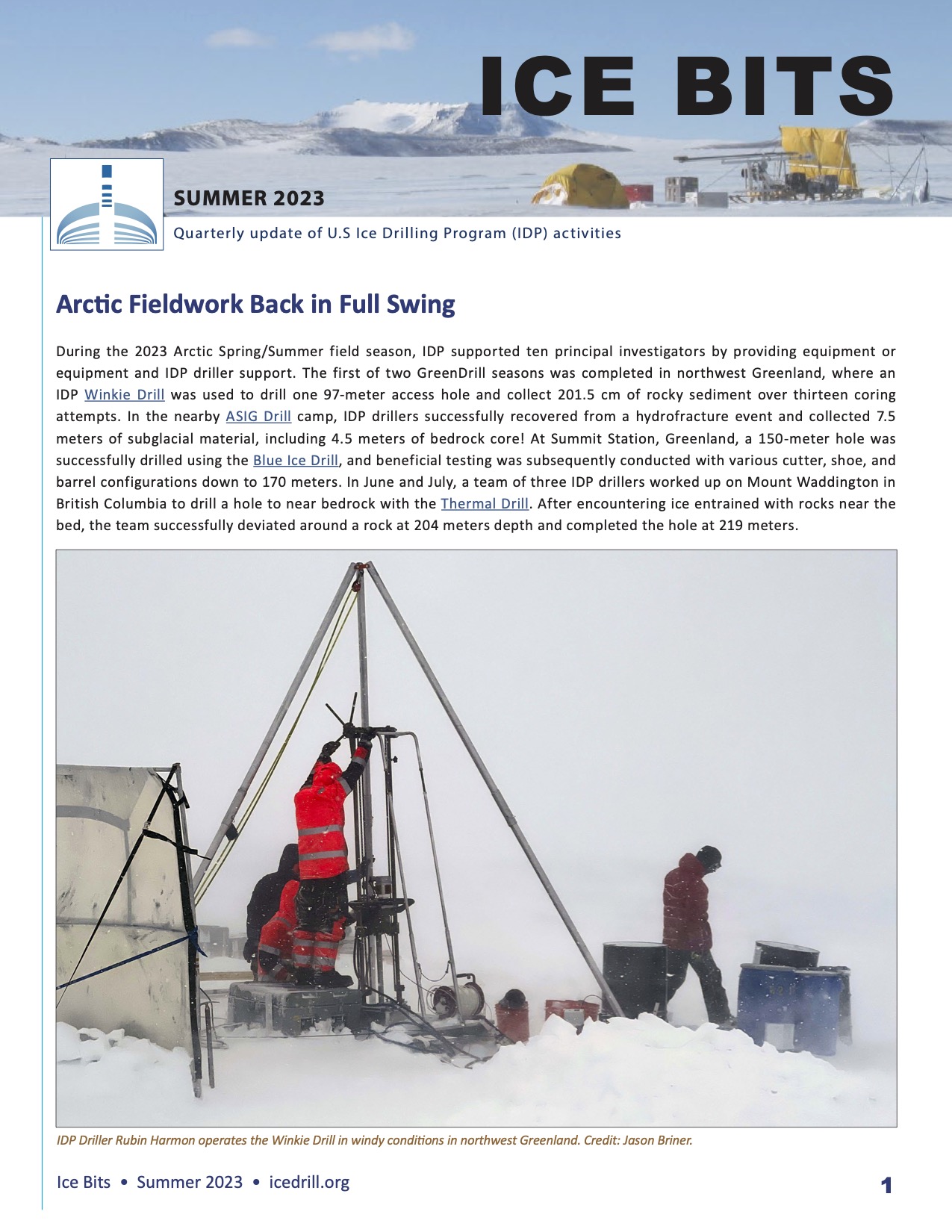

- Arctic Fieldwork Back in Full Swing

- New 700 Drill Takes Shape

- IDP Welcomes New Mechanical Engineer Andrew Haala

- Climate of H.O.P.E. (How Our Planet is Evolving) Conference

- IDP Holds Successful School of Ice at Dartmouth

- IDP Train the Trainers Workshop Extends the Reach of IDP Resources

- 2023-2033 Long Range Science and Long Range Drilling Technology Plans Updated

- Stay Connected with IDP

- Ice Drilling Support for NSF Polar Proposals

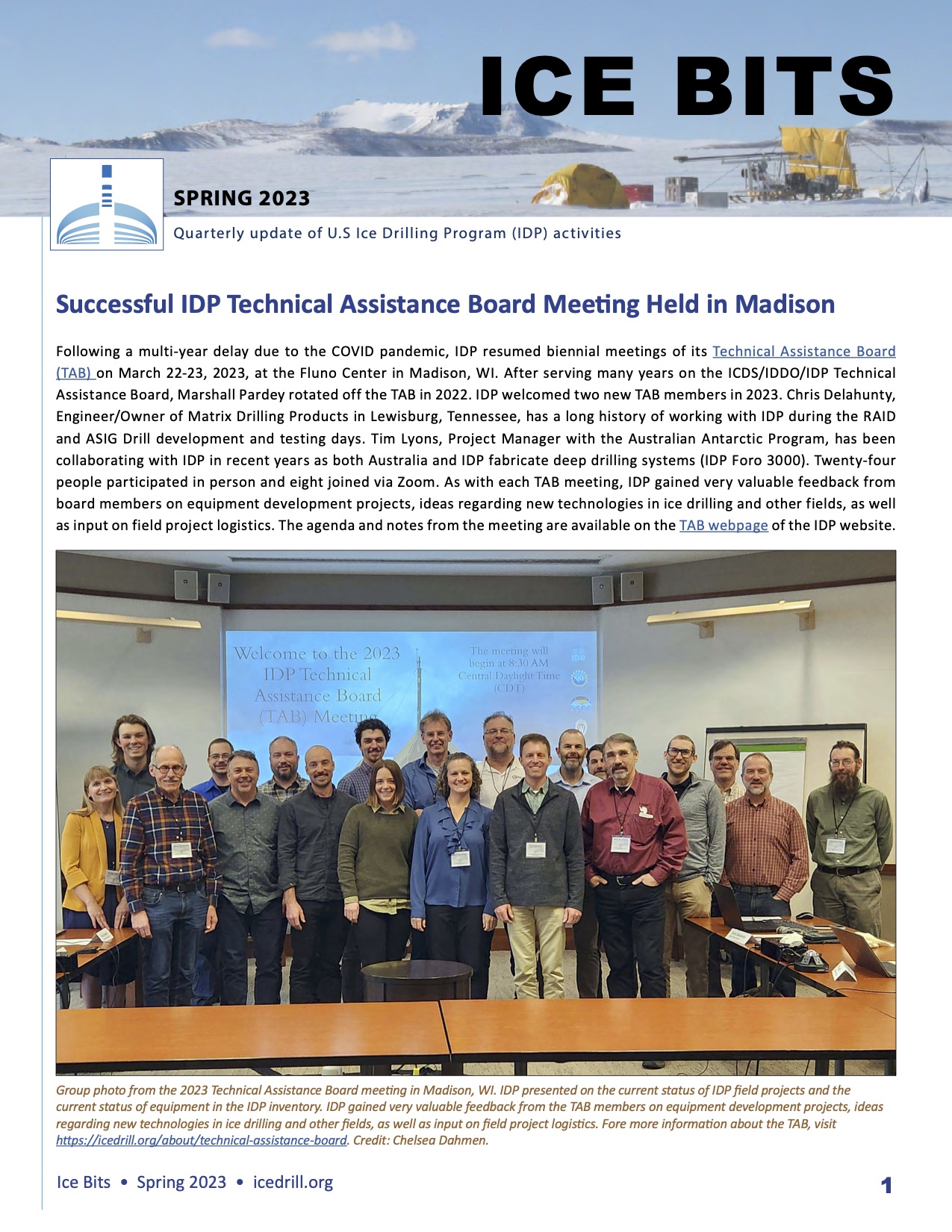

Topics:

- Successful IDP Technical Assistance Board Meeting Held in Madison

- Drill Maintenance and Testing in Full Swing at IDP-WI

- IDP EO Planning Two Summer Workshops and Hires New EO Specialist

- 2023 Spring/Summer Fieldwork

- Science Advisory Board 2023 Meeting

- Ice Core Working Group 2023 Meeting

- Stay Connected with IDP

- Ice Drilling Support for NSF Polar Proposals

Topics:

- IDP Returns to Antarctica!

- Two New Virtual Field Labs – Climate Warnings from Alaska and Comparing Climate Change Past and Present

- IDP Letter of Support for Pre-proposal Concept Outlines for USAP Antarctic Fieldwork

- IDP Policy for Acknowledgements

- Stay Connected with IDP

- Ice Drilling Support for NSF Polar Proposals

Topics:

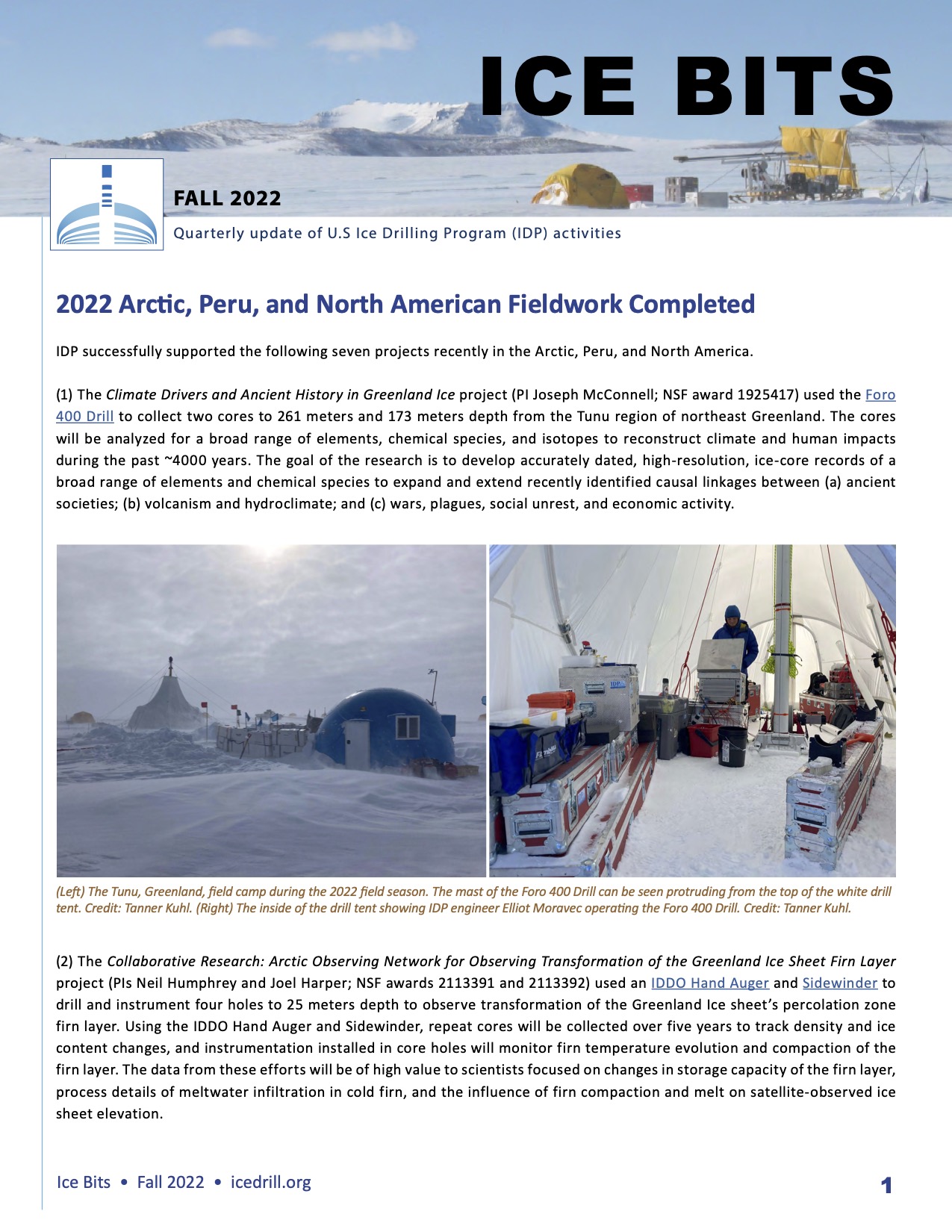

- 2022 Arctic, Peru, and North American Fieldwork Completed

- Field Support to Antarctic 2022-2023 Projects

- Ice Core Articles for Undergraduate Students and Ice Core-Adjacent Researchers

- School of Ice 2023 Workshop

- IDP Education Resources Selected for Inclusion in CLEAN

- Center for Oldest Ice Exploration (COLDEX) REU Program

- Ice Core Sessions at AGU Fall Meeting

- Stay Connected with IDP

- Acknowledgment of IDP in Publications

- Ice Drilling Support for NSF Polar Proposals

Topics:

- ASIG Drill Departs Madison for Upcoming GreenDrill Project

- Equipment Testing in Full Swing

- IDP Welcomes New Field Support Manager Jess Ackerman

- IDP Ice Drilling Community Survey

- 2022-2032 Long Range Science and Long Range Drilling Technology Plans Updated

- IDP Education and Public Outreach Update Summer 2022

- Stay Connected with IDP

- Acknowledgment of IDP in Publications

- Ice Drilling Support for NSF Polar Proposals

Topics:

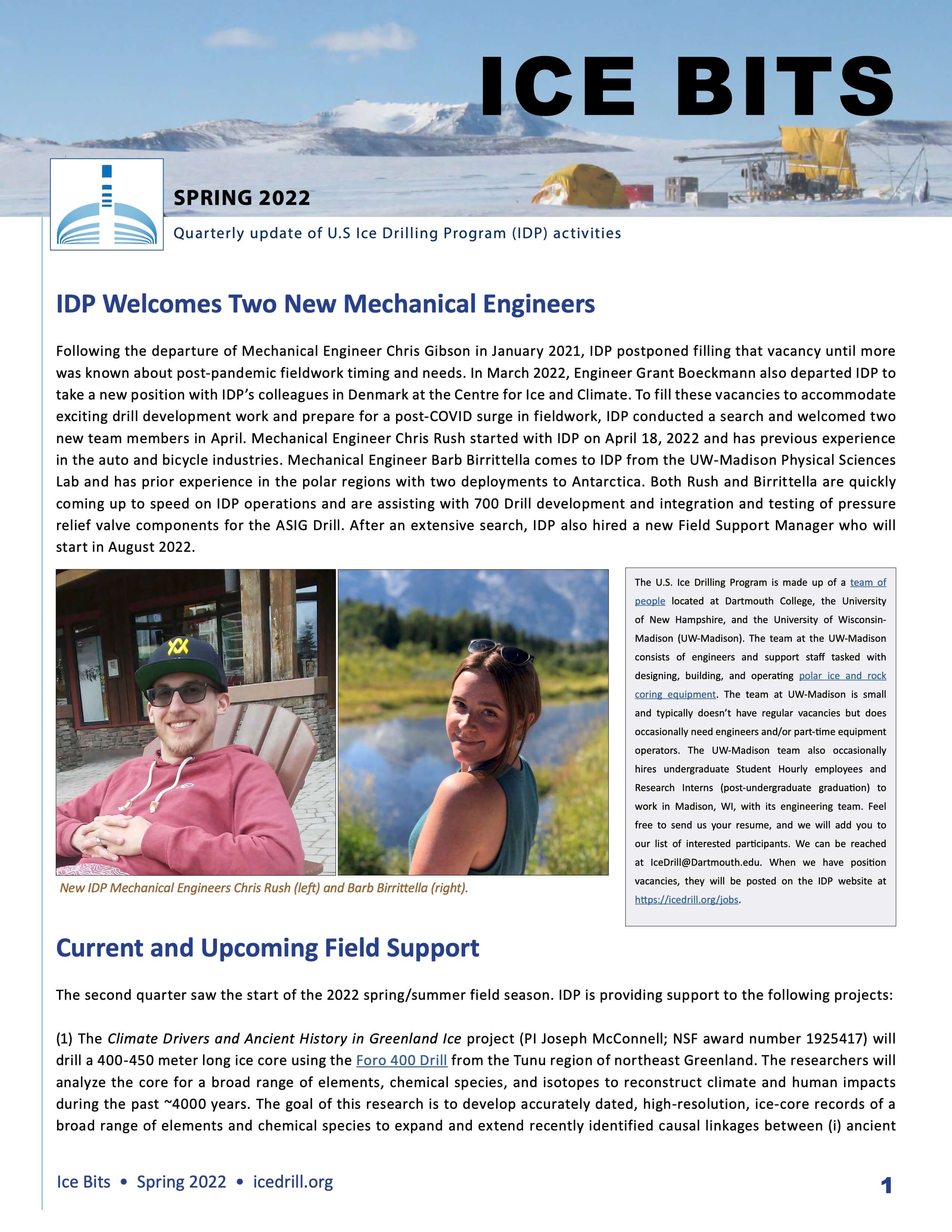

- IDP Welcomes Two New Mechanical Engineers

- Current and Upcoming Field Support

- IDP Education and Public Outreach Update Spring 2022

- Basal Access and Sampling Feasibility Study – New White Paper from IDP

- Ice Core Working Group 2022 Meeting

- Science Advisory Board 2022 Meeting

- Stay Connected with IDP

- Acknowledgment of IDP in Publications

- Ice Drilling Support for NSF Polar Proposals

Topics:

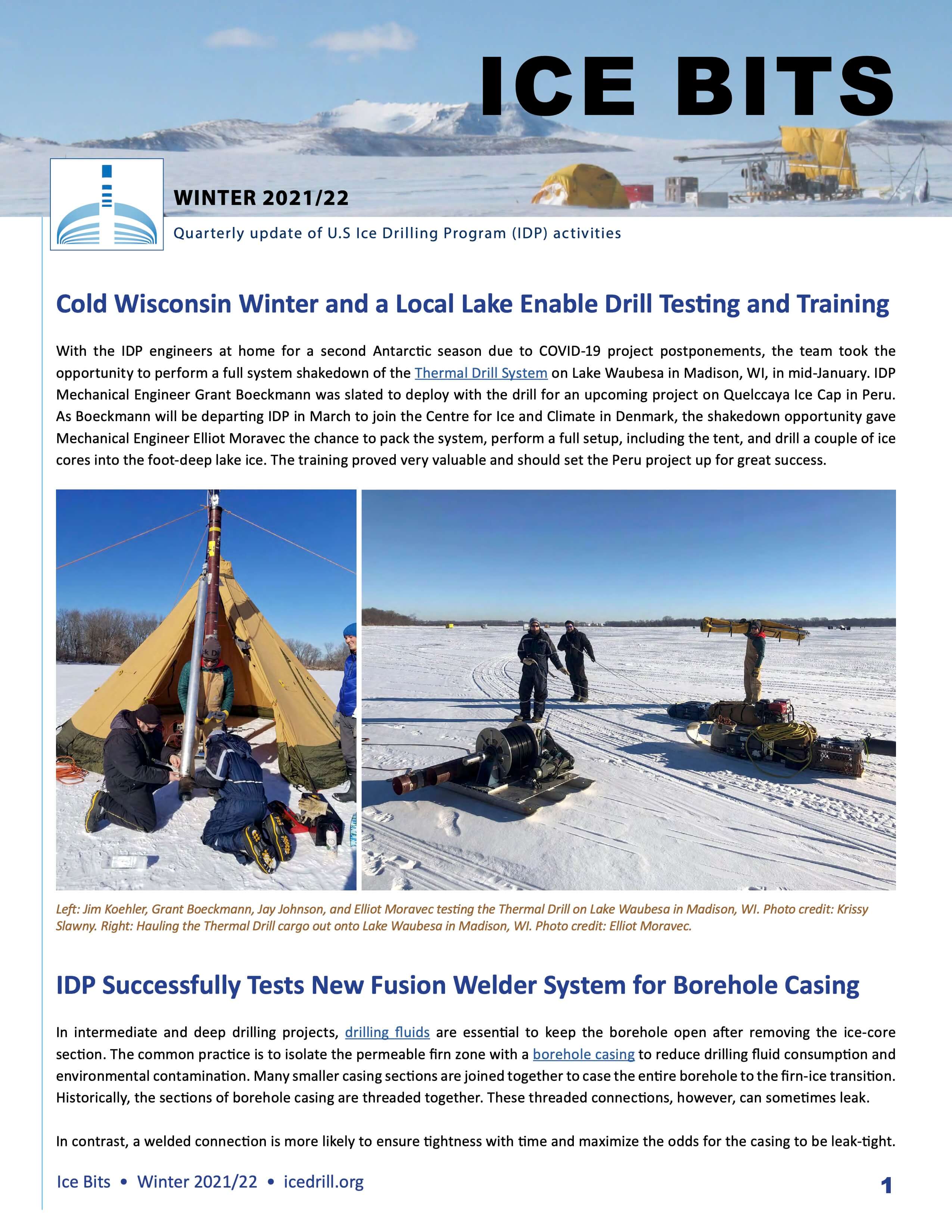

- Cold Wisconsin Winter and a Local Lake Enable Drill Testing and Training

- IDP Successfully Tests New Fusion Welder System for Borehole Casing

- 700 Drill Fabrication Approved

- IDP Hires New Electrical Engineer and Seeks a New Field Support Manager and Mechanical Engineer(s)

- Announcing School of Ice - Summer 2022

- Save the Date - US Ice Core Open Science Meeting, May 24-26, 2022

- Stay Connected with IDP

- Acknowledgment of IDP in Publications

- Ice Drilling Support for NSF Polar Proposals

Topics:

- IDP Education and Outreach Resources

- AGU Town Hall (Online Only): Scientific Drilling in the Polar Regions

- Mark Twickler Retires After 35+ Years Involved in Ice Drilling

- IDP-WI Equipment Development and Maintenance Update

- IDP's Library – A Portal to Ice Drilling Technology Documents

- International Partnerships in Ice Core Sciences (IPICS) 3rd Open Science Conference

- Stay Connected with IDP

- Acknowledgment of IDP in Publications

- Ice Drilling Support for NSF Polar Proposals

Topics:

- 2021-2031 Long Range Science and Long Range Drilling Technology Plans Updated

- Successful School of Ice Held at Oregon State University

- 700 Drill Detailed Design Progress

- Ice Core Early Career Researchers Workshop (ICECReW)

- Presentations Available - U.S. Science Traverses on the Greenland Ice Sheet: a Planning Workshop

- DISC Drill - Survey of Community Interest

- Science Requirements: Replicate Coring for the Foro 3000 Drill

- Acknowledgment of IDP in Publications

- Ice Drilling Support for NSF Polar Proposals

Topics:

- Beneficial Drill System Testing and Operator Training Conducted near Madison, WI

- Science Advisory Board 2021 Meeting

- Ice Core Working Group 2021 Meeting

- Request for Community Input — DRAFT 2021 Long Range Science Plan

- IDP Education and Public Outreach Update Spring 2021

- U.S. Scientific Traverses on the Greenland Ice Sheet: a Planning Workshop

- Acknowledgment of IDP in Publications

- Ice Drilling Support for NSF Polar Proposals

Topics:

- COVID-19 Pandemic Postpones Fieldwork but Allows for Beneficial Development, Maintenance and Upgrade Work

- 700 Drill

- Innovative Virtual Field Labs Offer New Participatory Experiences for Online Learning

- School of Ice 2021

- IDP Science Advisory Board Meeting March 18-19, 2021 and Call for Input into the Long Range Science Plan

- Early Career Travel Grant Opportunity for the 2021 IPICS & ICYS meeting

- Hercules Dome Ice Core Project: Community Workshop and Webinar Events

- ICYS International Ice Core Seminar Series

- Acknowledgment of IDP in Publications

- Ice Drilling Support for NSF Polar Proposals

Topics:

- AGU Town Hall: Scientific Drilling in the Polar Regions

- Early Career Travel Grant Opportunity for the 2021 IPICS & ICYS meeting

- Ice Drilling Support for NSF Polar Proposals

Topics:

- 2020-2030 Long Range Science and Long Range Drilling Technology Plans Updated

- 2020 Ice Core Working Group White Papers

- 2020 Science Advisory Board (SAB) Meeting and SAB Rotations

- IDP-WI Refocuses on Development and Maintenance Work Amid COVID-19 Pandemic

- COVID-19 Transformed 2020 School of Ice is Successfully Executed

- Acknowledgment of IDP in Publications

- Ice Drilling Support for NSF Polar Proposals

Topics:

- IDP Hires New Field Support Manager and New Mechanical Engineer

- Ice Core Working Group (ICWG) Community Planning Workshop

- School of Ice Transitions to Virtual Workshop Format

- Teacher Activities Highlighting Ice Science and Engineering

- Request for Community Input - Draft 2020 Long Range Science Plan

- Acknowledgment of IDP in Publications

- Ice Drilling Support for NSF Polar Proposals

Topics:

- IDP Supports a Successful 2019/20 Antarctic Field Season

- IDP Active Engagement at AGU Fall Meeting

- Early Career Travel Opportunity for the IPICS & ICYS Meeting

- IDP Ice Core Science Community Planning Workshop

- Call for Input – Long Range Science Plan 2020-2029

- Acknowledgment of IDP in Publications

- Ice Drilling Support for NSF Polar Proposals

Topics:

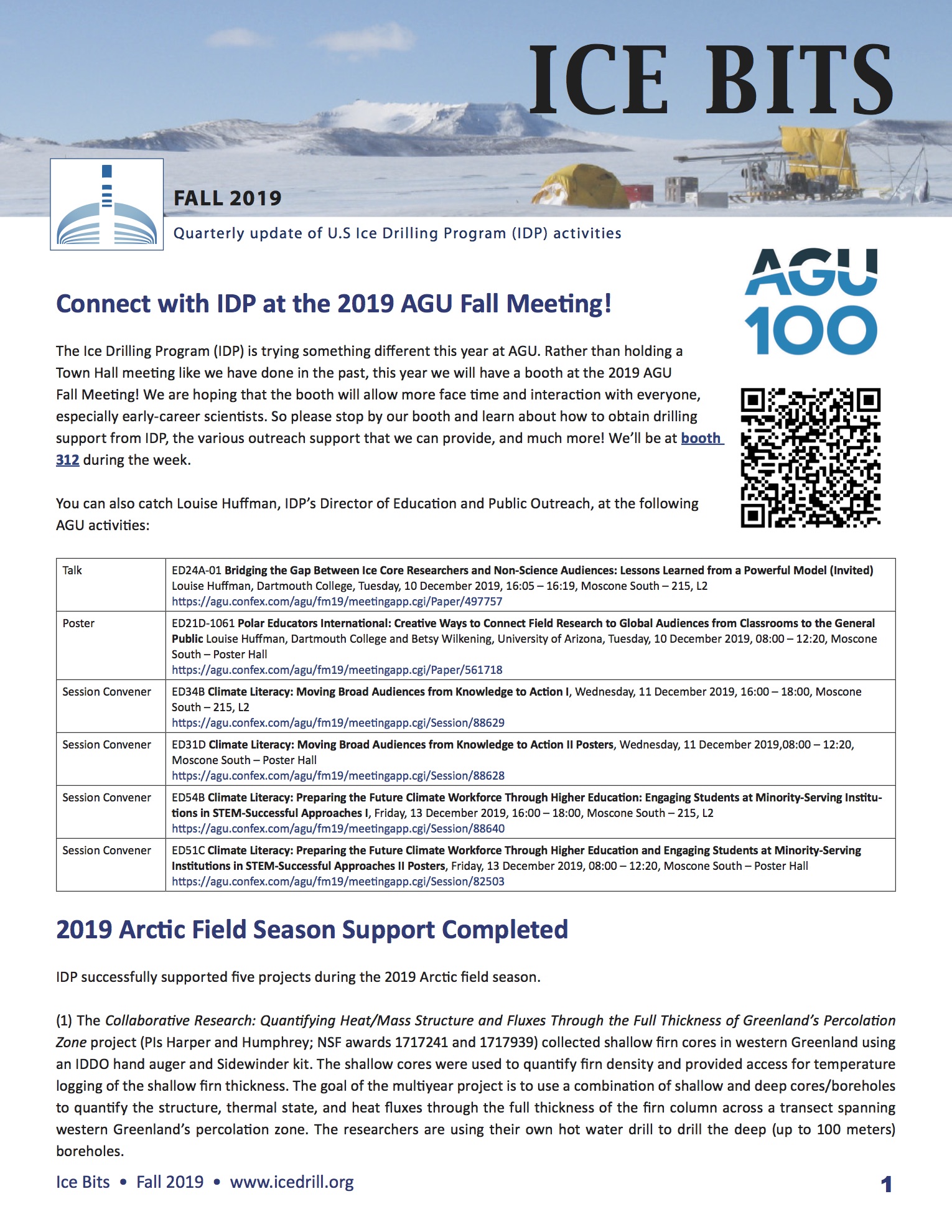

- Connect with IDP at the 2019 AGU Fall Meeting!

- 2019 Arctic Field Season Support Completed

- Field Support to Antarctic 2019-2020 Projects

- Field Support to Northern Hemisphere Winter/Spring 2019-2020 Projects

- International Partnerships in Ice Core Sciences 3rd Open Science Conference – Ice Core Science at the three Poles

- Save the Date! IDP Ice Core Working Group Community Planning Workshop April 2-3, 2020

- Ice Drilling Support for NSF Polar Proposals

Topics:

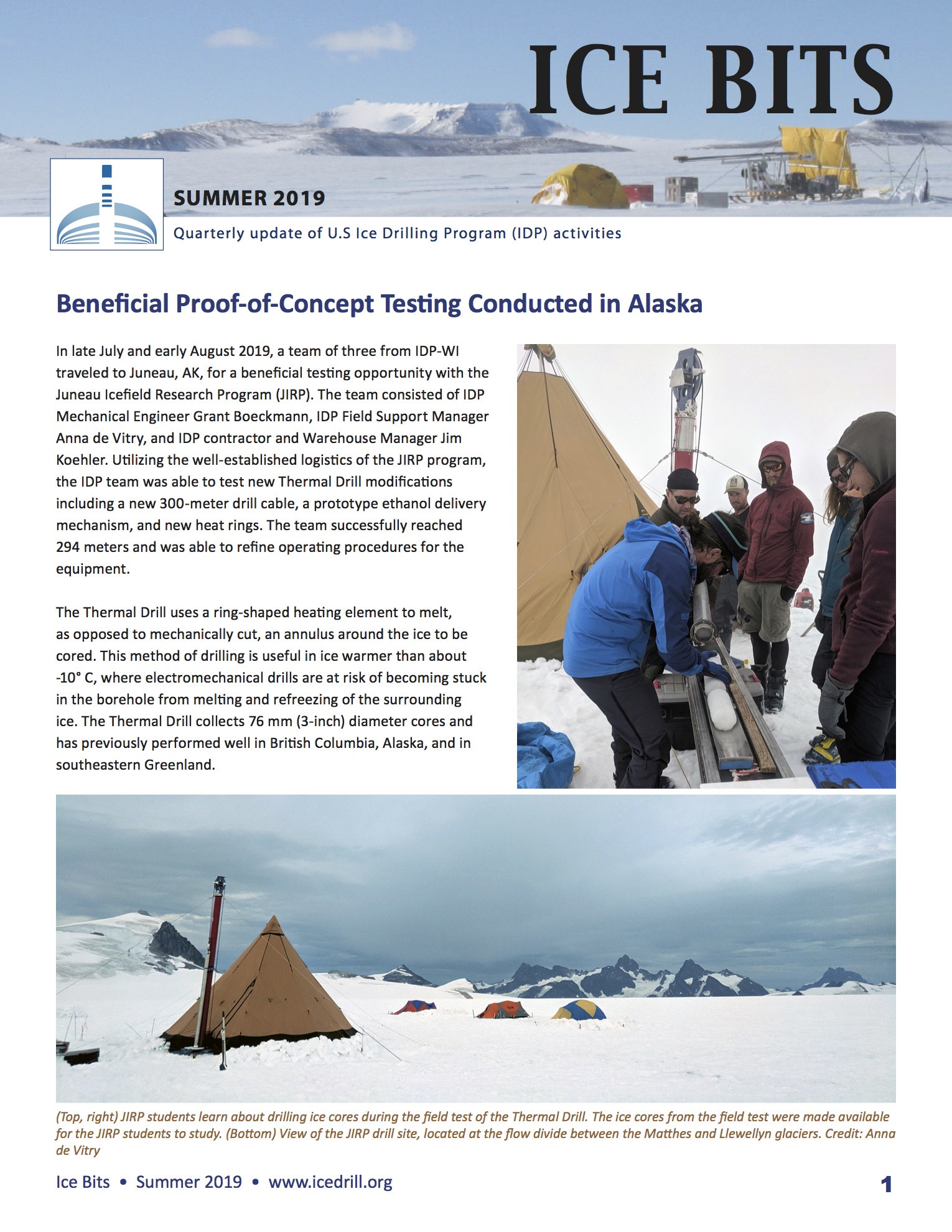

- Beneficial Proof-of-Concept Testing Conducted in Alaska

- Foro 3000 Fabrication Underway

- 2019 IDP School of Ice Workshop

- IDP Education and Outreach at TEDxMileHigh Summer Event

- 2019-2029 Long Range Science and Long Range Drilling Technology Plans Updated

- Ice Drilling Support for NSF Polar Proposals

Topics:

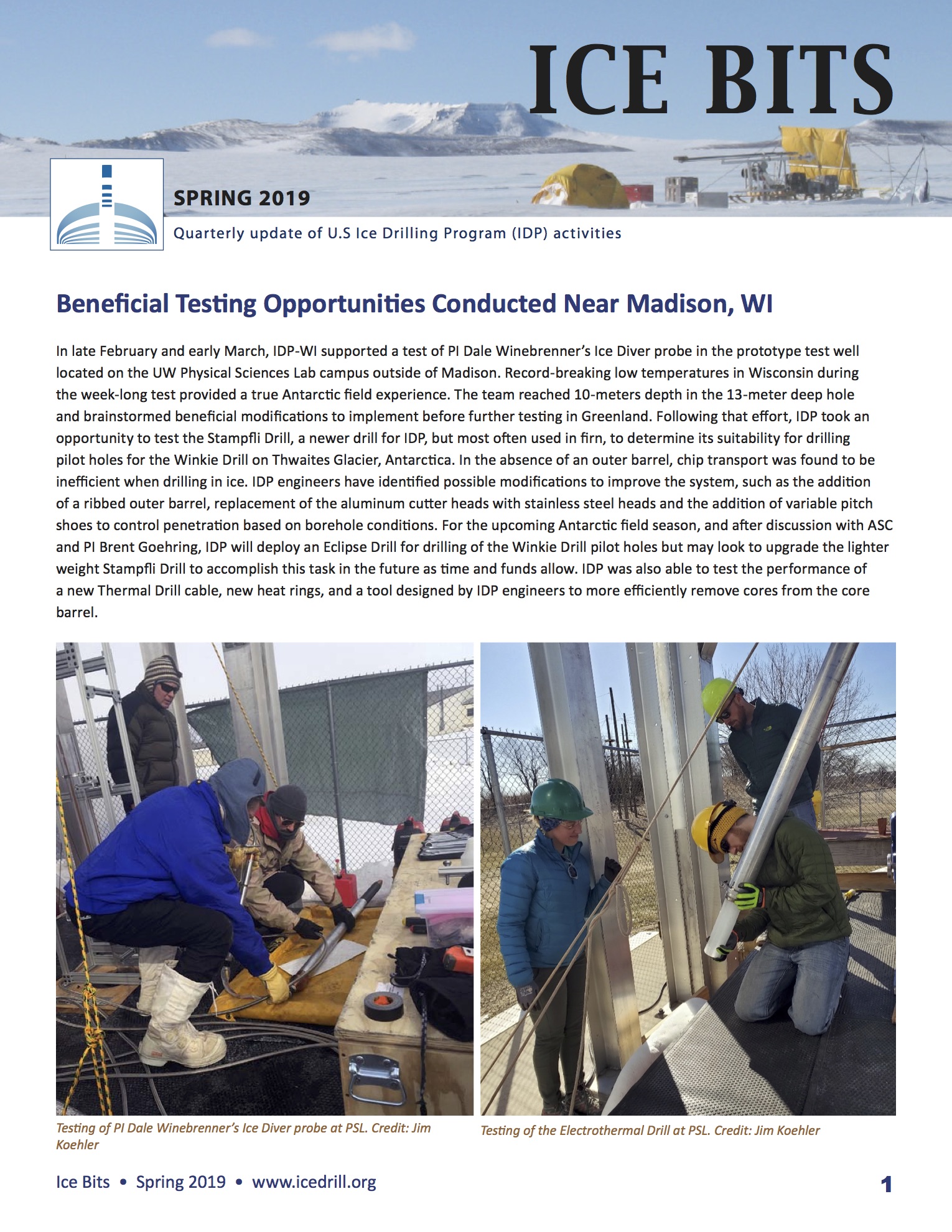

- Beneficial Testing Opportunities Conducted Near Madison, WI

- Field Support to 2019 Arctic Projects

- IDP Subglacial Access Working Group Science Planning Workshop

- Education and Public Outreach (2019 Spring)

- The MECC and Other Antarctic Cargo Returns

- Ice Drilling Support for NSF Polar Proposals

Topics:

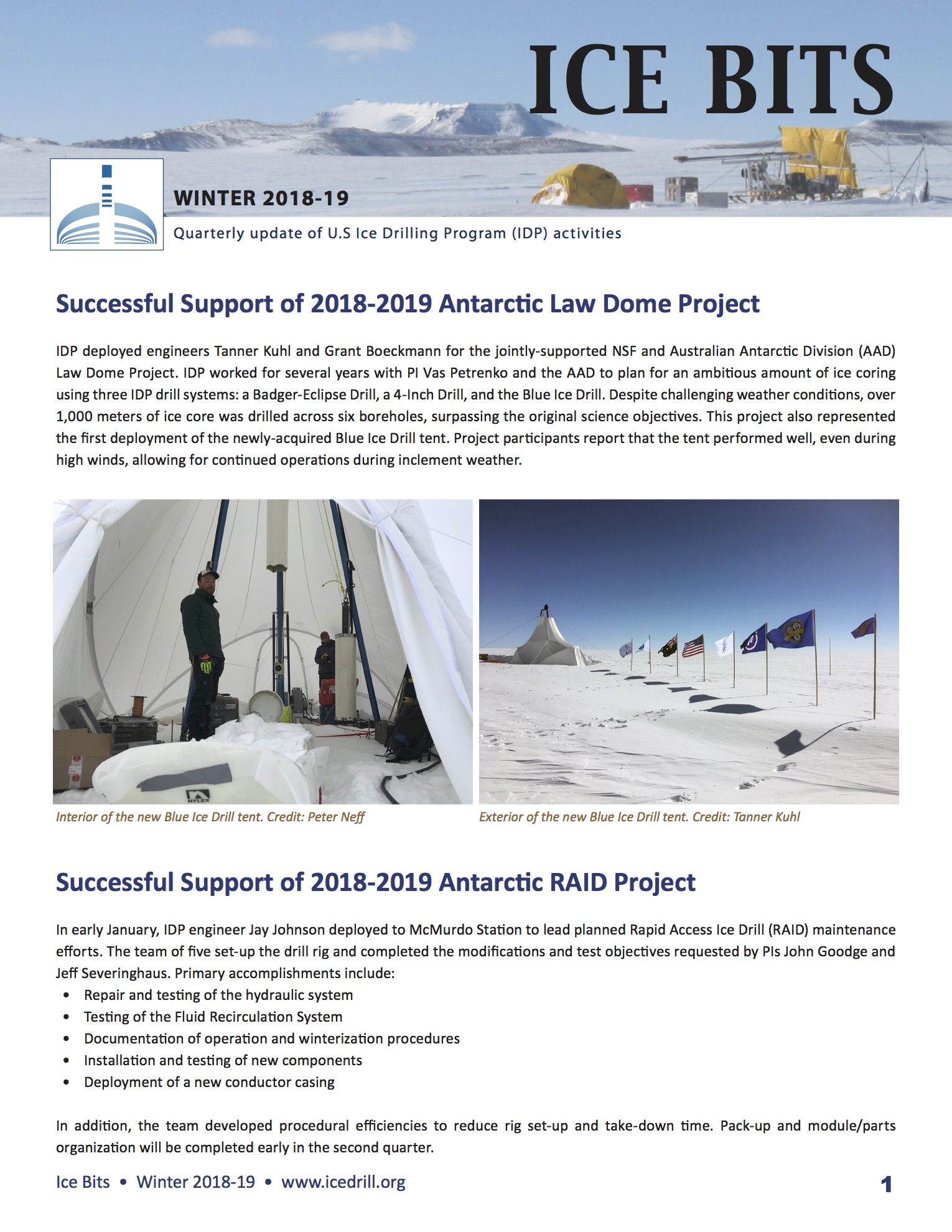

- Successful Support of 2018-2019 Antarctic Law Dome Project

- Successful Support of 2018-2019 Antarctic RAID Project

- Subglacial Access Science Planning Workshop: March 29-30, 2019

- Call for Input - Long Range Science Plan

- Education and Outreach Update (2018 Winter)

- IDP Hosts Successful Town Hall at AGU Fall Meeting

- Acknowledgment of IDP in Publications

- Ice Drilling Support for NSF Polar Proposals

Topics:

- AGU Town Hall 2018: Scientific Drilling in the Polar Regions

- 2018 Arctic Field Season Support Completed

- Field Support to Antarctic 2018-2019 Projects

- Subglacial Access Science Planning Workshop: March 29-30, 2019

- Education and Outreach Update (2018 Fall)

- Ice Drilling Support for NSF Polar Proposals

Topics:

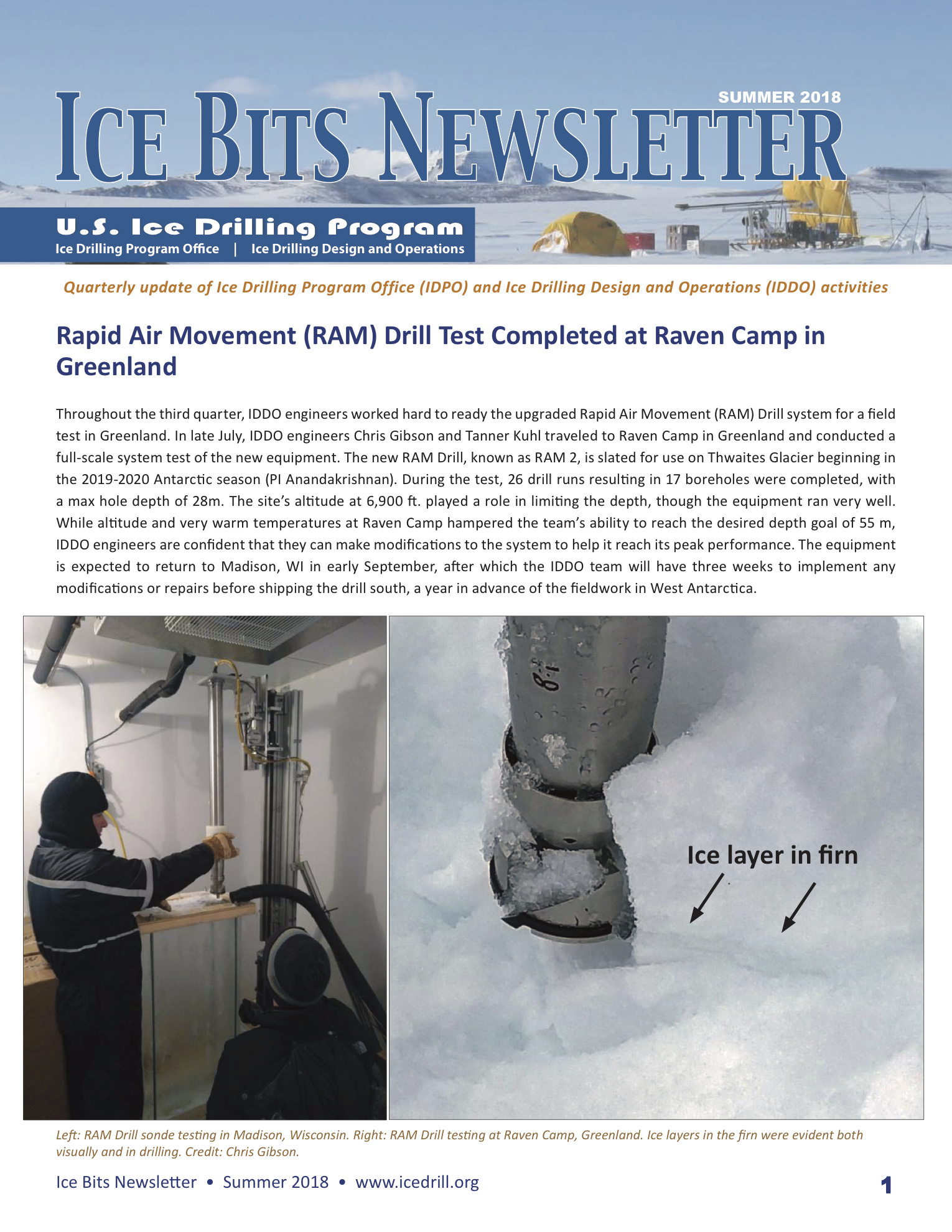

- Rapid Air Movement (RAM) Drill Test Completed at Raven Camp in Greenland

- Antarctic Cargo Preparation Commences for Law Dome Project

- Equipment Updates (2018 Summer)

- 2018 School of Ice

- IDPO Education and Outreach at POLAR2018

- 2018-2028 Long Range Science and Long Range Drilling Technology Plans Updated

- Ice Drilling Support for NSF Polar Proposals

Topics:

- Rapid Air Movement Drill Upgrades in Full Swing at IDDO

- Field Support to 2018 Arctic Projects

- 2018 Technical Advisory Board Meeting

- Equipment Updates (2018 Spring)

- IDPO Education and Public Outreach Workshops at NSTA

Topics:

- IDDO Completes Support of 2017-2018 Antarctic Season

- IDPO Ice Core Working Group Tackles Science-Technology Tradeoffs

- Equipment Updates (2017 Winter)

- IDPO Hosts Successful Town Hall at AGU Fall Meeting

- Antarctic Science Generates Enthusiasm at an IDPO Education and Public Outreach Event at Rutgers University

- Call for Input - Long Range Science Plan

- Ice Drilling Support for NSF Polar Proposals

Topics:

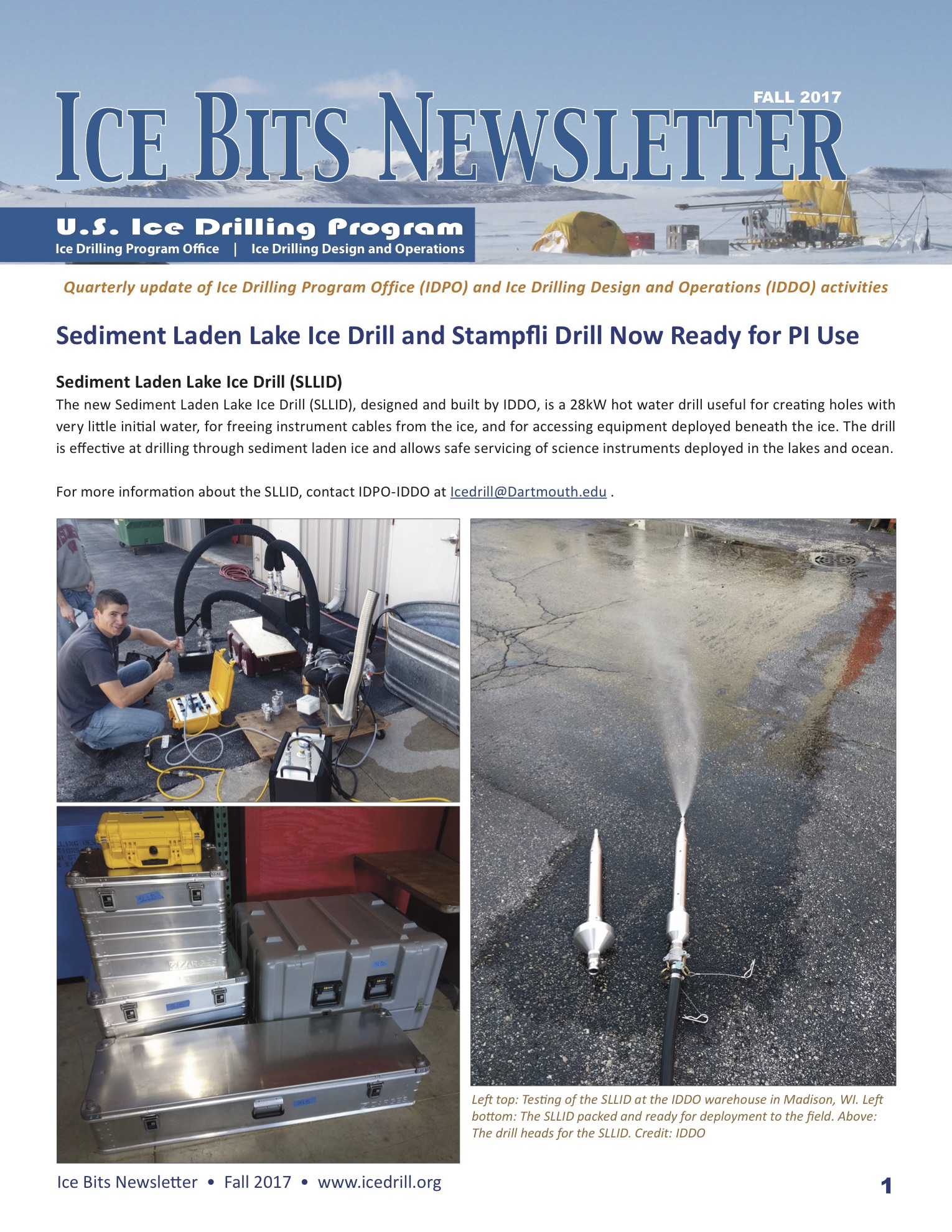

- Sediment Laden Lake Ice Drill and Stampfli Drill Now Ready for PI Use

- Field Support to Antarctic 2017-2018 Projects

- Scientific Drilling in the Polar Regions AGU 2017 Town Hall Meeting

- Announcing new IDPO Education and Outreach Website

- Announcing School of Ice 2018

- Requesting Ice Drilling Support (2017 Fall)

Topics:

- IDDO Welcomes New Mechanical Engineer/Project Manager

- IDDO Finishes Successful 2017 Arctic Field Season

- Equipment Development (2017 Summer)

- 2017-2027 Long Range Science and Long Range Drilling Technology Plans Updated

- School of Ice Development Program Successfully Held at Dartmouth College

- NAAEE Outreach Event

- Dr. Julie Palais Awarded Richardson Medal

- Charles Bentley, Pioneering UW-Madison Glaciologist, Dies

- Charlie Bentley Commemorative Event

Topics:

- IDDO Welcomes New Field Support Manager

- Antarctic Cargo Returns to Madison

- Field Support to 2017 Arctic Projects

- Equipment Development (2017 Spring)

- IDPO and IDDO Lead Successful Science Advisory Board and Technical Advisory Board Meetings in Madison, WI

- White Papers from the Subglacial Access Science Community Planning Workshop Available

- IDPO Involved in Multiple Education and Outreach Events (2017 Spring)

- IDDO Driller, Robb Kulin, Selected by NASA to Join the 2017 Astronaut Candidate Class

- Requesting Ice Drilling Support (2017 Spring)

Topics:

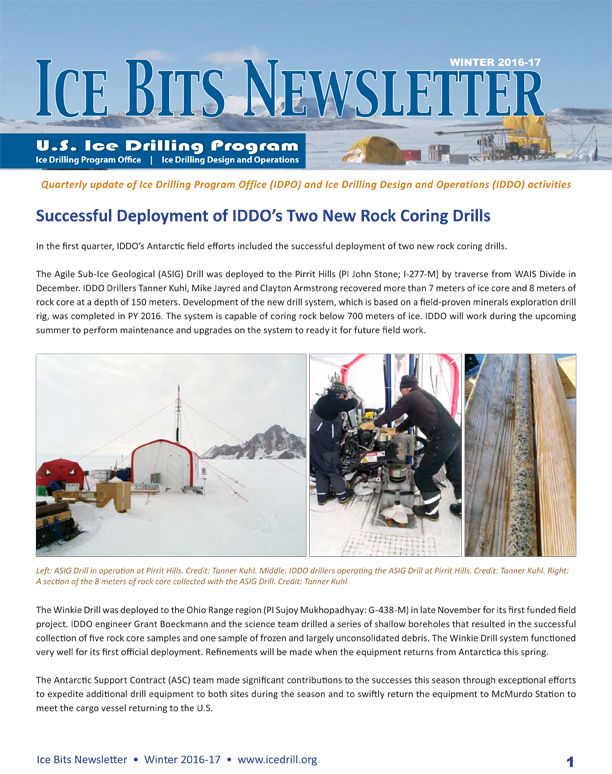

- Successful Deployment of IDDO's Two New Rock Coring Drills

- 2016-2017 Antarctic Field Season Wraps Up

- Equipment Development (2016 Winter)

- IDPO Involved in Multiple Education and Outreach Events (2016 Winter)

- IDPO Hosts Successful Town Hall at AGU 2016 Fall Meeting

- Requesting Ice Drilling Support (2016 Winter)

Topics:

- IDDO Equipment On Its Way to Antarctica for 2016-2017 Field Season

- Field Support to Antarctic 2016-2017 Projects

- Equipment Development (2016 Fall)

- Scientific Drilling in the Polar Regions AGU 2016 Town Hall Meeting

- Call for Nominations: Science Advisory Board to the U.S. Ice Drilling Program Office

- 2016 Technical Advisory Board Meeting

- Education and Outreach (2016 Fall)

- Requesting Ice Drilling Support (2016 Fall)

- Field Support to Science Projects (2016 Fall)

Topics:

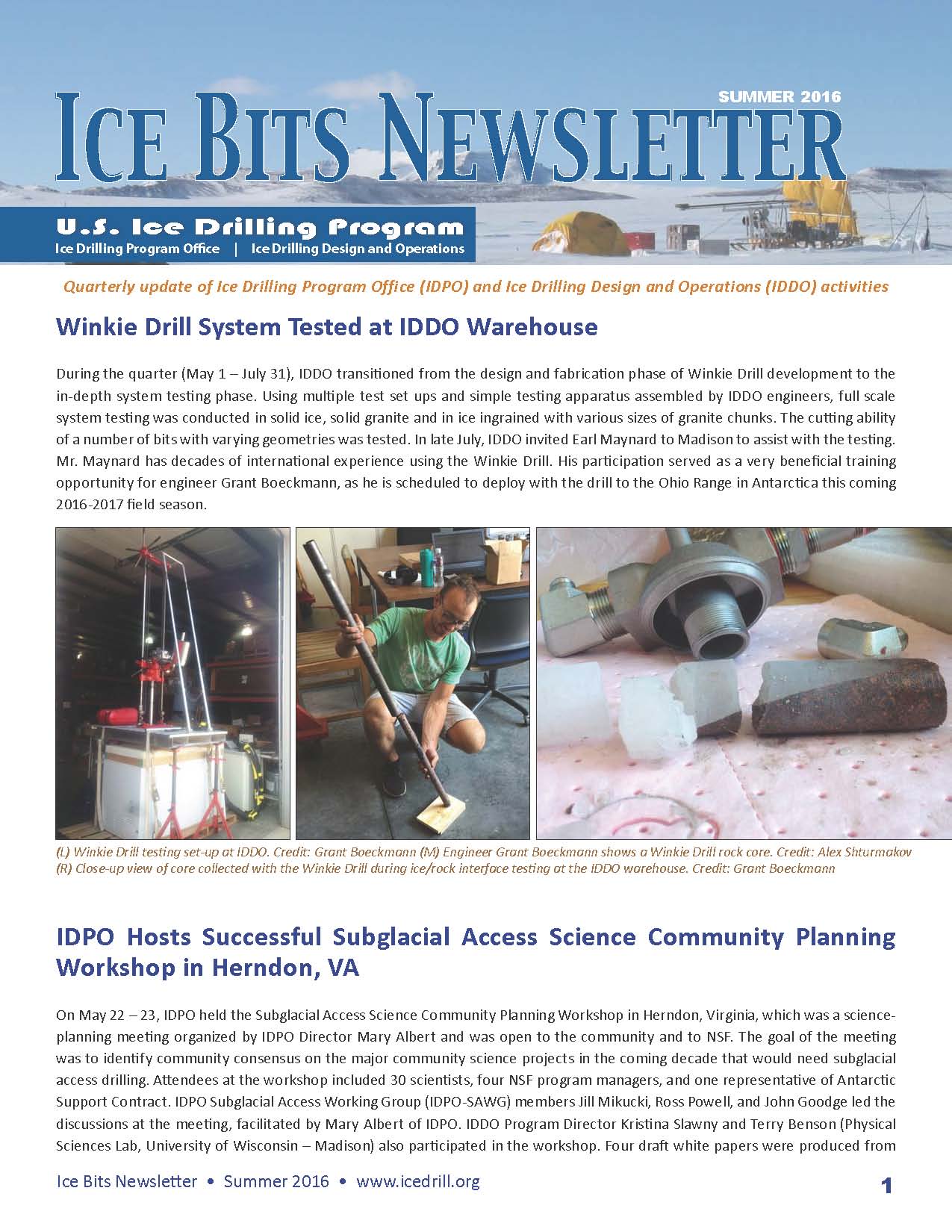

- Winkie Drill System Tested at IDDO Warehouse

- IDPO Hosts Successful Subglacial Access Science Community Planning Workshop in Herndon, VA

- GreenTrACS Successfully Uses IDDO Hand Auger and Sidewinder to Collect Shallow Ice Cores

- Equipment Development (2016 Summer)

- 2016-2026 Long Range Science and Long Range Drilling Technology Plans Updated

- IDPO Involved in Multiple Education and Outreach Events (2016 Summer)

- IDDO Field Support Manager Vacancy

- Requesting Ice Drilling Support (2016 Summer)

Topics:

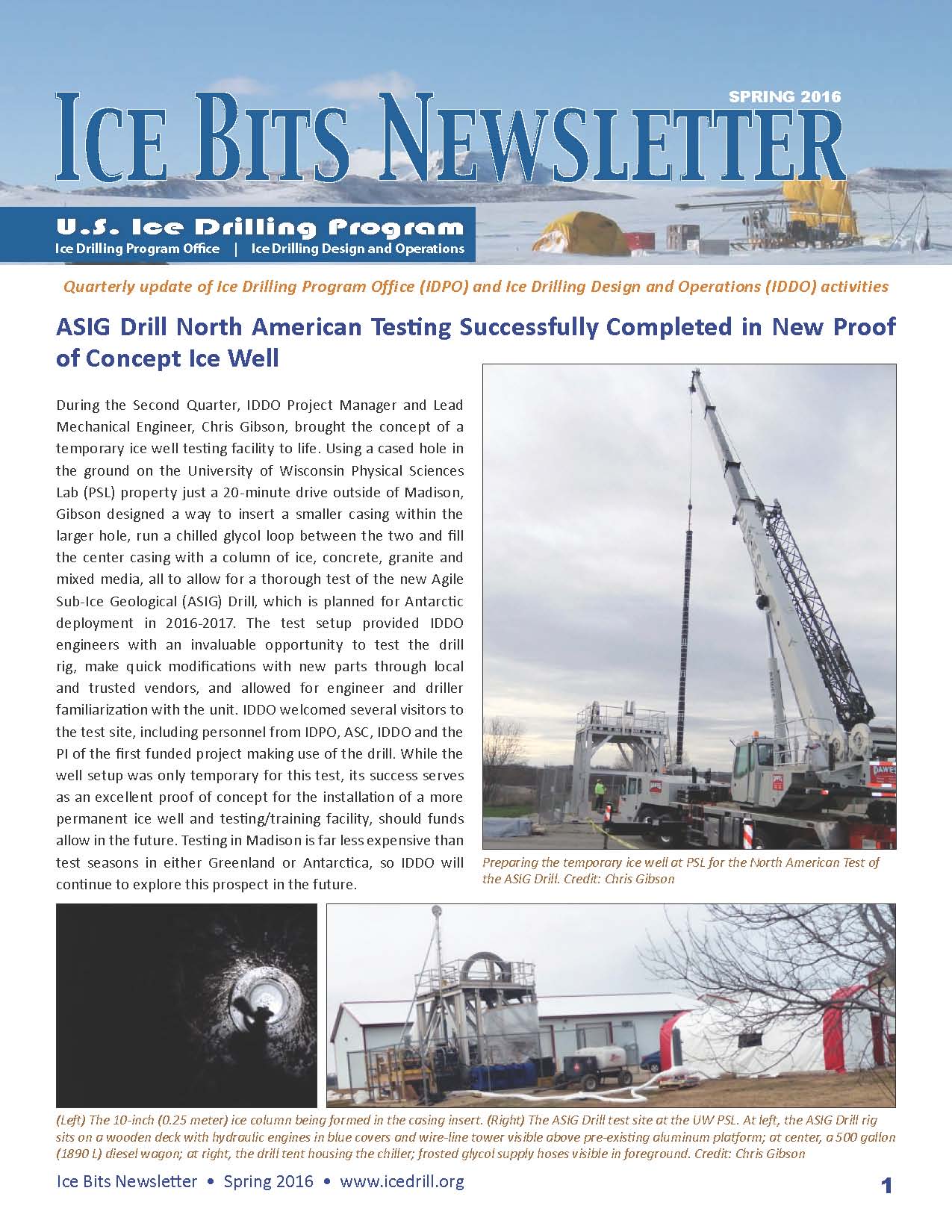

- ASIG Drill North American Testing Successfully Completed in New Proof of Concept Ice Well

- Winkie Drill Development in Full Swing

- IDPO Leads Multiple Events at the National Science Teachers Association Conference

- Equipment Development (2016 Spring)

- IDPO Leads Successful Science Advisory Board Meeting in Arlington, VA

- Acknowledgement of IDPO-IDDO in Publications (2016 Spring)

- Updated Data Management and Data Reporting Requirements for NSF Division of Polar Programs Research Awards

- Requesting Ice Drilling Support (2016 Spring)

- Drilling Support to Science Projects (2016 Spring)

Topics:

- SPICECORE Drilling Successfully Surpasses Depth Goal!

- Successful Support Across Antarctica

- Equipment Development (2015 Winter)

- IDPO Education and Public Outreach: Linda Morris Retires and Louise Huffman is Hired

- April 4, 2016 Deadline for Requesting Ice Drilling Support for NSF Antarctic Research Proposals

- Subglacial Access Drilling: IDPO Science Planning Workshop 2016

- IDPO Hosts Successful Town Hall at AGU 2015 Fall Meeting

Topics:

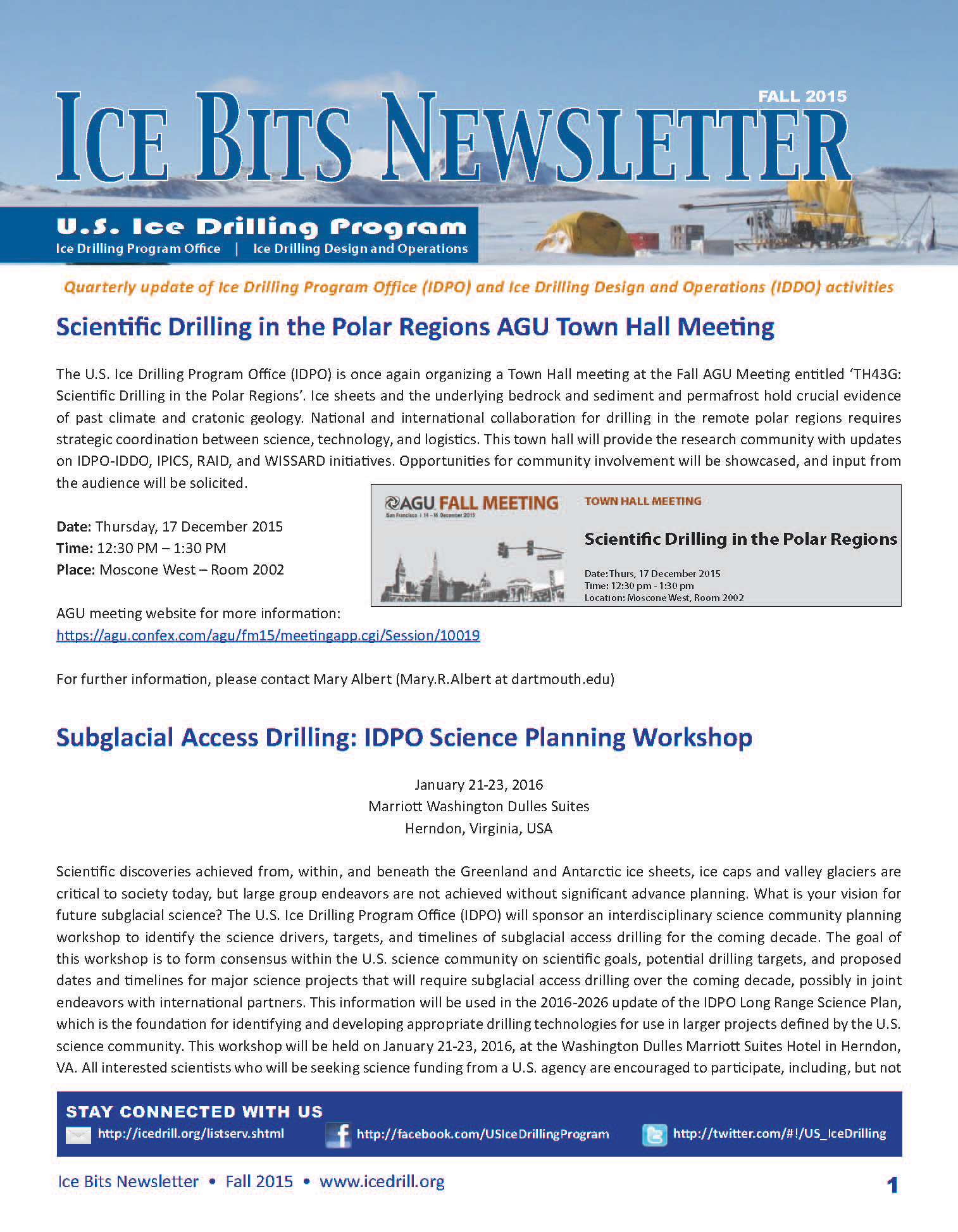

- Scientific Drilling in the Polar Regions AGU 2015 Town Hall Meeting

- Subglacial Access Drilling: IDPO Science Planning Workshop (2015 Fall)

- Applications Sought for IDPO's School of Ice 2016

- Field Support to Antarctic Projects (2015 Fall)

- 2015 Technical Advisory Board Meeting

Topics:

- Beneficial, User-Identified Upgrades Made to IDDO Small Hot Water Drill

- IDPO Launches New Course Targeting Professors at Minority-Serving Institutions

- Acknowledgement of IDPO-IDDO in Publications (2015 Summer)

- Scientific Field Support (2015 Summer)

- Equipment Development (2015 Summer)

- 2015-2025 Long Range Science and Long Range Drilling Technology Plans Updated

- APECS IDPO Webinar

- Ice Core Working Group Virtual Meeting

- Borehole Logging Working Group Presentation

Topics:

- IDDO Receives Minerals Exploration Rig; Enters Exciting New Avenue of Subglacial Rock Coring

- Greenland Firn Aquifer Project Battles Tremendous Snowfall

- IDDO Continues Collaboration with UW PSL Hot Water Drilling Experts to Make User-Identified Upgrades to Small Hot Water Drills

- Beneficial Design Upgrades Continue for 4-Inch 'Foro' Drill

- IDPO Advances School of Ice

- IDPO Leads Successful 2015 Science Advisory Board Meeting in Arlington, VA

- Requesting Ice Drilling Support (2015 Spring)

- Drilling Support to Science Projects (2015 Spring)

Topics:

- Rewarding Debut of Intermediate Depth Drill at South Pole Station

- Continued Success on Taylor Glacier

- WAIS Divide Schedule Challenges and Achievements

- ASIG Drill Development Project Paves the Way for Subglacial Access

- IDPO Hosts Successful Town Hall at AGU 2014 Fall Meeting

- Preparations Underway for School of Ice, a Professional Development Course

- NSTA Web Seminar – Fire and Ice: Snow Albedo and Our Future

Topics:

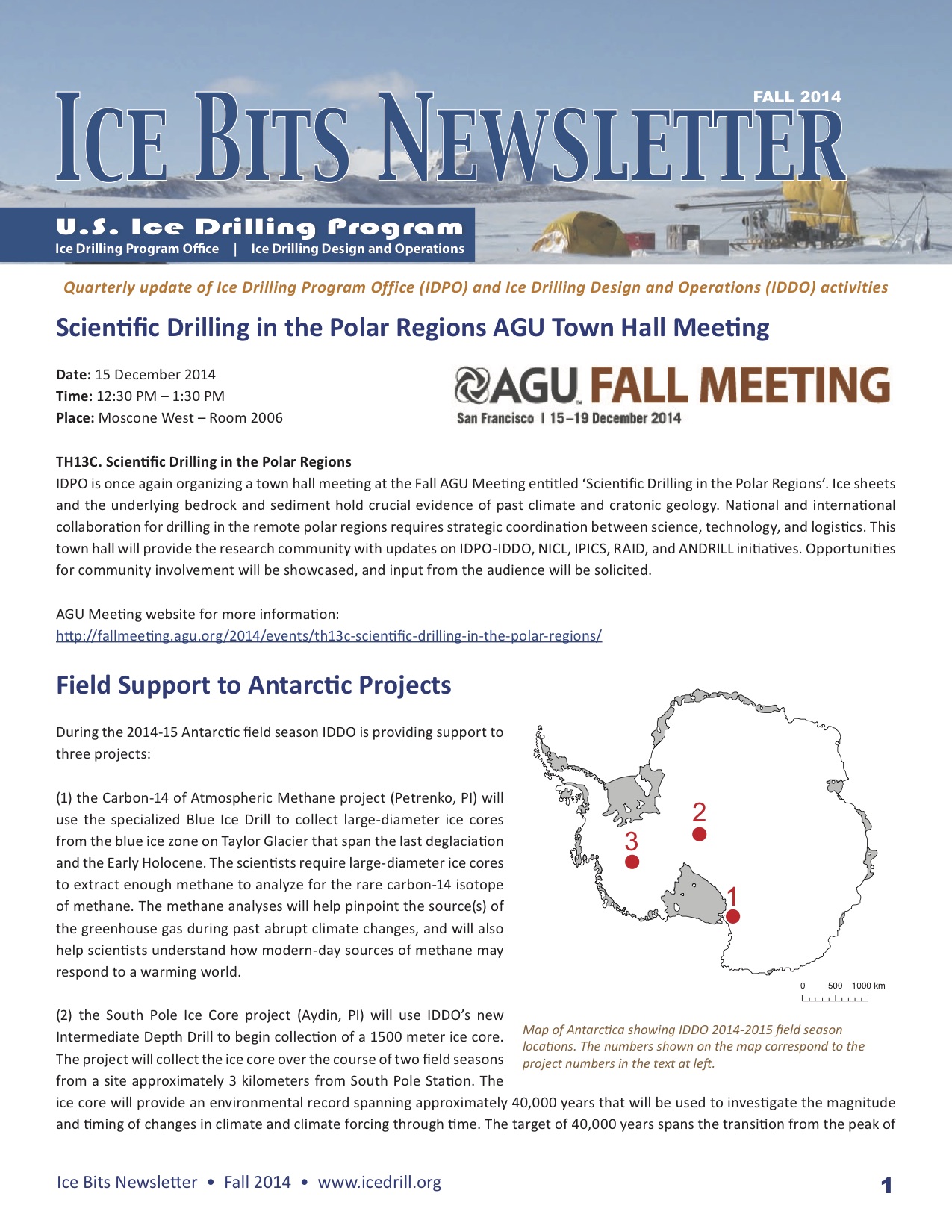

- Scientific Drilling in the Polar Regions AGU 2014 Town Hall Meeting

- Field Support to Antarctic Projects (2014 Fall)

- Education and Public Outreach (2014 Fall)

- 2014 Technical Advisory Board Meeting

- Media Kit (2014 Fall)

- Field Support to Science Projects (2014 Fall)

Topics:

- Long Range Planning Identifies the Direction of Research and Enables Drilling Technology

- IDPO Leads Reviews of Two IDDO Drills in Development

- Successful Field Test of IDDO's new Intermediate Depth Drill System in Greenland

- Cosmogenic Carbon-14 Core Project Successfully Completed Following Early Season Challenges

- IDPO Educational Outreach Develops New Interactive Map

- New Technology for the Community (2014 Summer)

- Construction of the Rapid Access Ice Drill (RAID) Begins!

- Don Lebar Retires After Nearly 13 Years as Head of UW-Madison's Ice Drilling Group

Topics:

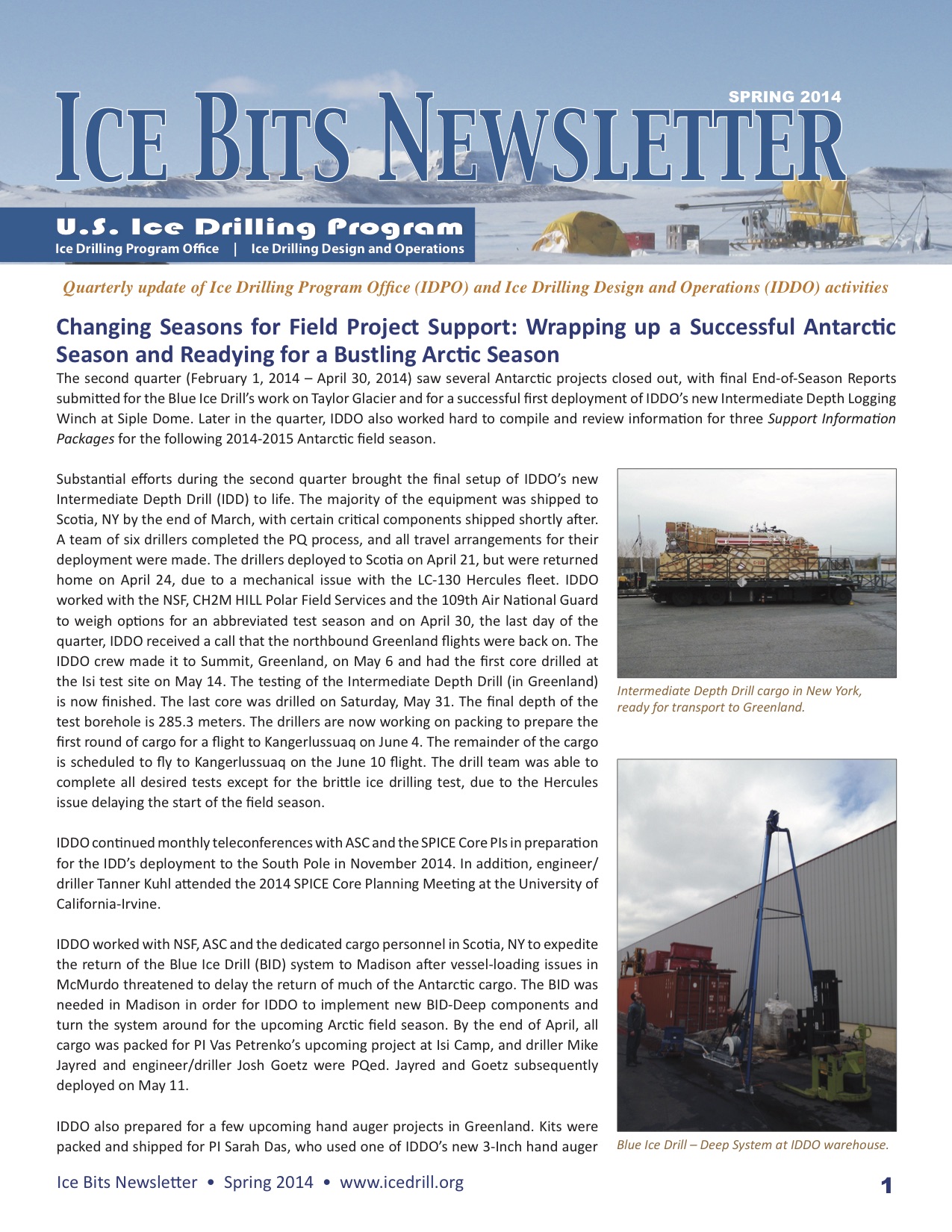

- Changing Seasons for Field Project Support: Wrapping up a Successful Antarctic Season and Readying for a Bustling Arctic Season

- New Technology for the Community (2014 Spring)

- IDPO Organized Workshop for Future Deep and Intermediate Depth Ice Coring

- Don Lebar Announces Retirement

- Drilling and Logging Support to Science Projects (2014 Spring)

Topics:

- Successful Project Support Amidst an Uncertain Antarctic Field Season

- Equipment Development (2013 Winter)

- Dartmouth, UNH and UW-Madison Continue Leadership of U.S. Ice Drilling Science and Engineering

- Educational Outreach (2013 Winter)

Topics:

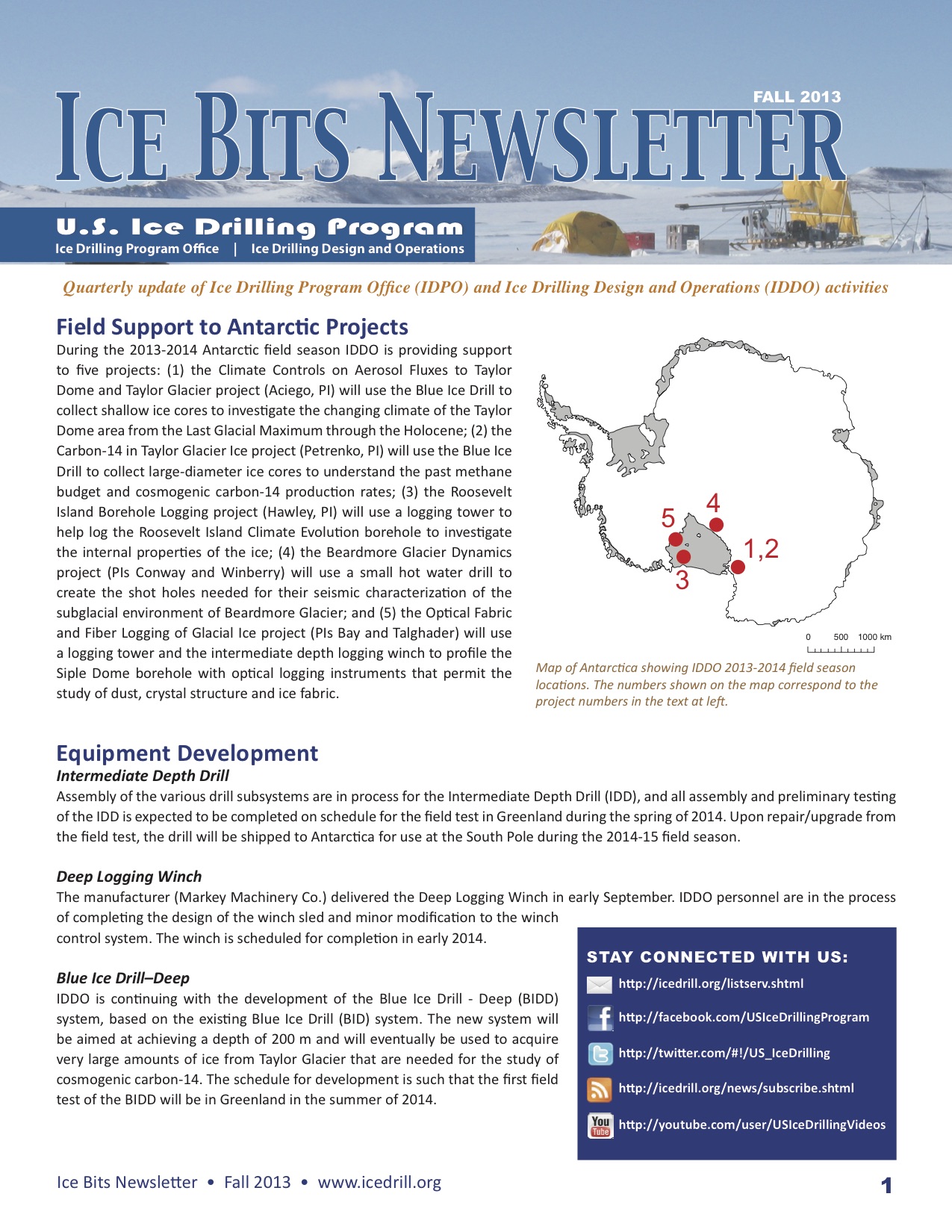

- Field Support to Antarctic Projects (2013 Fall)

- Equipment Development (2013 Fall)

- Scientific Drilling in the Polar Regions 2013 Town Hall Meeting

- Educational Outreach (2013 Fall)

- Field Support to Science Projects (2013 Fall)

Topics:

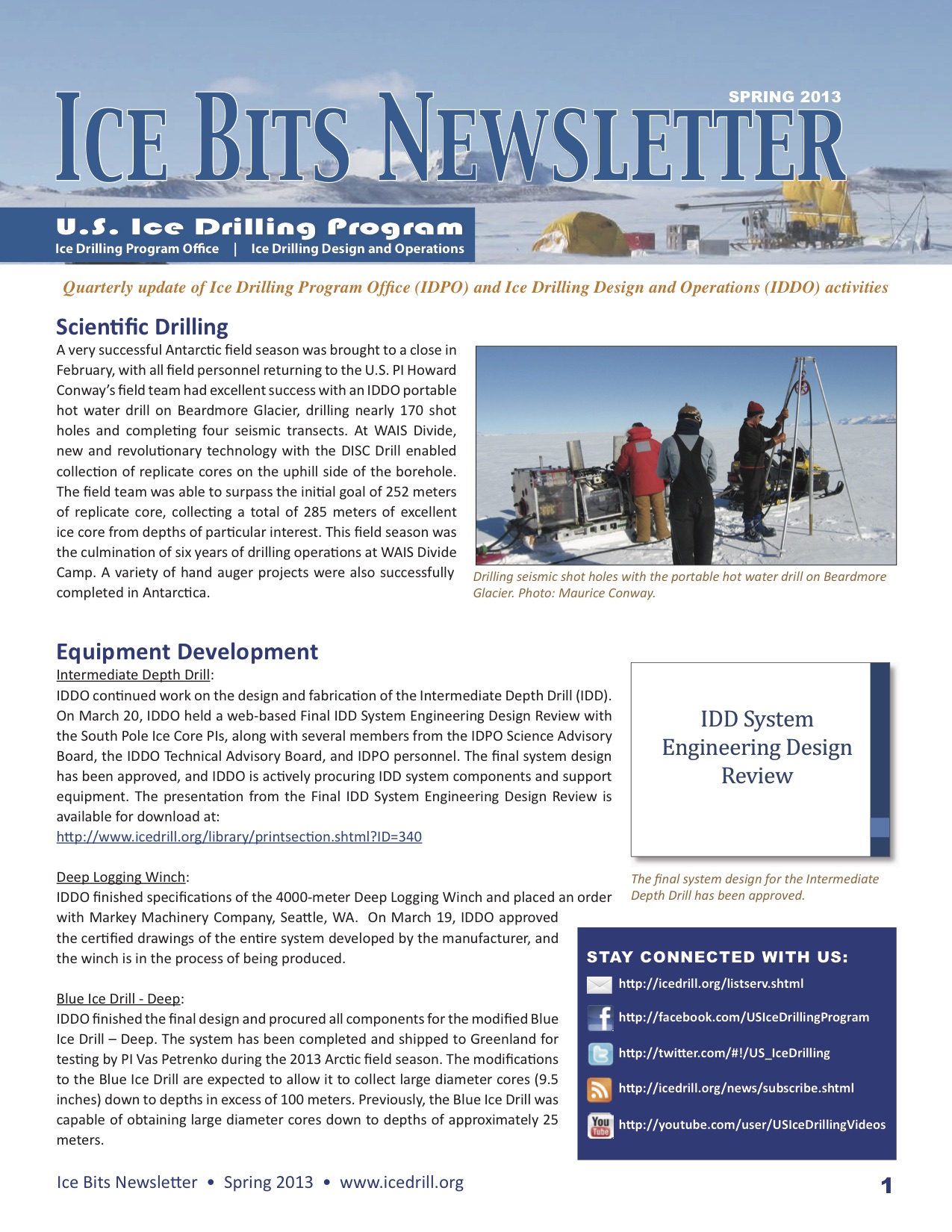

- Scientific Drilling (2013 Summer)

- Equipment Development (2013 Summer)

- Planning for the Future (2013 Summer)

- Educational Outreach (2013 Summer)

- Fiscal Challenges Facing the U.S. Antarctic Program — A Message to the U.S. Antarctic Program Research Community

- WAIS Divide Ice Core 2013 Science Meeting Reminder

- Conference Announcement: International Workshop on Ice Caves, Idaho Falls, USA, August 2014

- Drilling Support to Science Projects (2013 Summer)

Topics:

- Scientific Drilling (2013 Spring)

- Equipment Development (2013 Spring)

- Planning for the Future (2013 Spring)

- Registration and Abstract Submission Now Open - 7th International Workshop on Ice Drilling Technology

- WAIS Divide Ice Core 2013 Science Meeting

- New Video on Ice Core Processing

- Educational Outreach (2013 Spring)

- IDPO/IDDO Media Kit

- Drilling Support to Science Projects (2013 Spring)

Topics:

- Replicate Coring Ice Drilling Technology is Successful

- Intermediate Depth Drill

- NSF Press Release on the Completion of Deep Drilling at WAIS Divide, Antarctica

- 7th International Workshop on Ice Drilling Technology (Reminder)

- Deep Logging Winch

- IDPO Leads Community Events at AGU

- Planning for the Future (2012 Winter)

- Drilling Support to Science Projects (2012 Winter)

Topics:

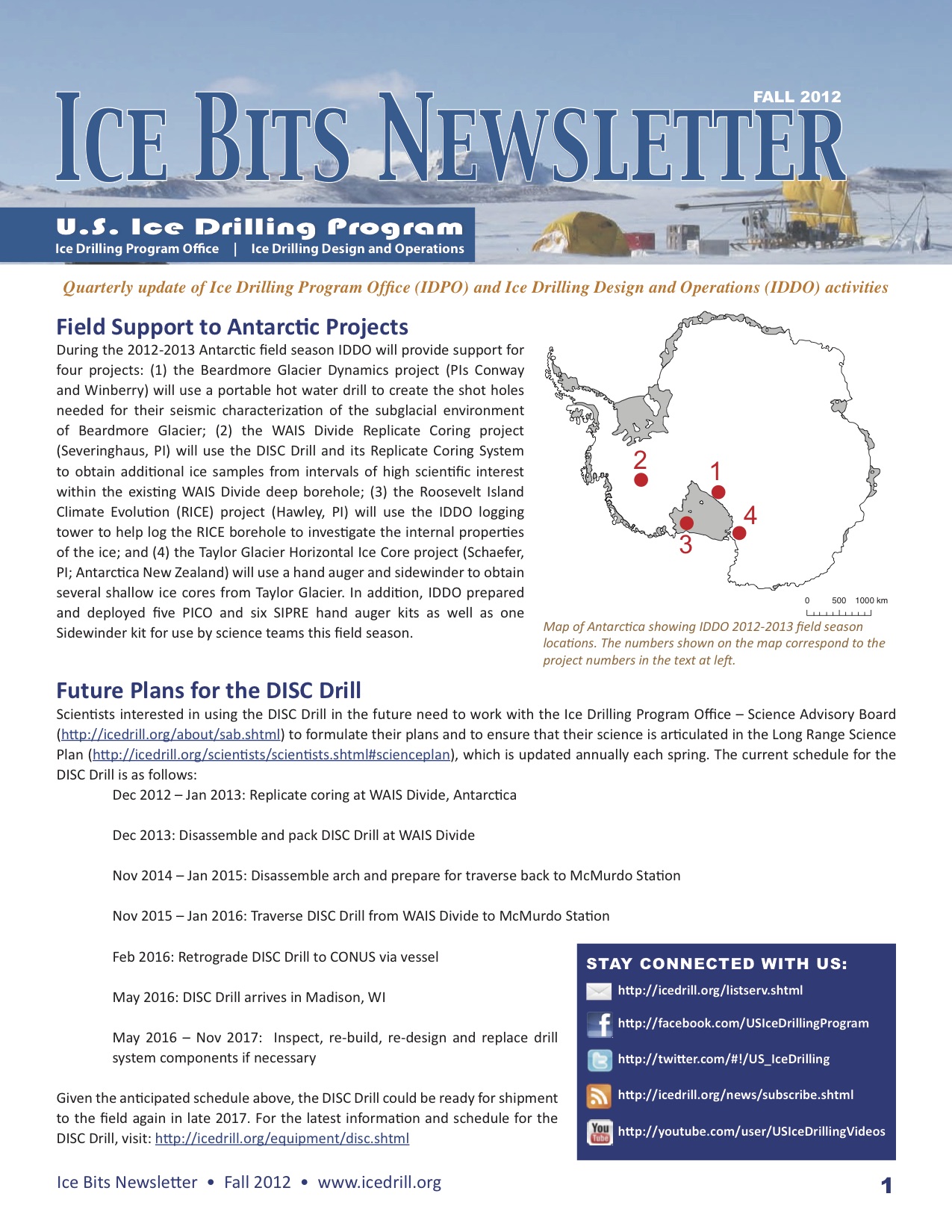

- Field Support to Antarctic Projects (2012 Fall)

- Future Plans for the DISC Drill

- Scientific Drilling in the Polar Regions 2012 Town Hall Meeting

- 7th International Workshop on Ice Drilling Technology

- Intermediate Depth Logging Winch Now Available for Community Use

- Educational Outreach (2012 Fall)

- Visit Us on Facebook

- NSF Solicitation for Ice Coring and Drilling Program for the Office of Polar Programs

- U.S. SCAR Office and ANSWER News Digest Move to Ohio State University

- South Pole 1500 m Ice Core

Topics:

- Replicate Coring System Characterization Testing Underway

- Intermediate Depth Drill Starts Taking Shape

- Intermediate Depth Logging Winch in Fabrication

- Rapid Access Ice Drill

- 2012 Technical Advisory Board Meeting

- GISP2 Borehole Casing

- New Drilling Fluid

- Change Management Policy

- New Outreach Effort

- Educational Outreach (2012 Summer)

- Ice Drilling Technology Workshop Proceedings

Topics:

- 2011-2012 Antarctic Field Season Successfully Completed

- DISC Drill Replicate Coring Testing

- Badger-Eclipse Drill Utilized for Driller Training

- New Hand Auger Prototype Tested

- Rapid Access Drill Feasibility

- Science Advisory Board Working Groups

- Educational Outreach (2012 Spring)

- Drilling Support to Science Projects (2012 Spring)

- U.S. Ice Drilling Program Media Kit

Topics:

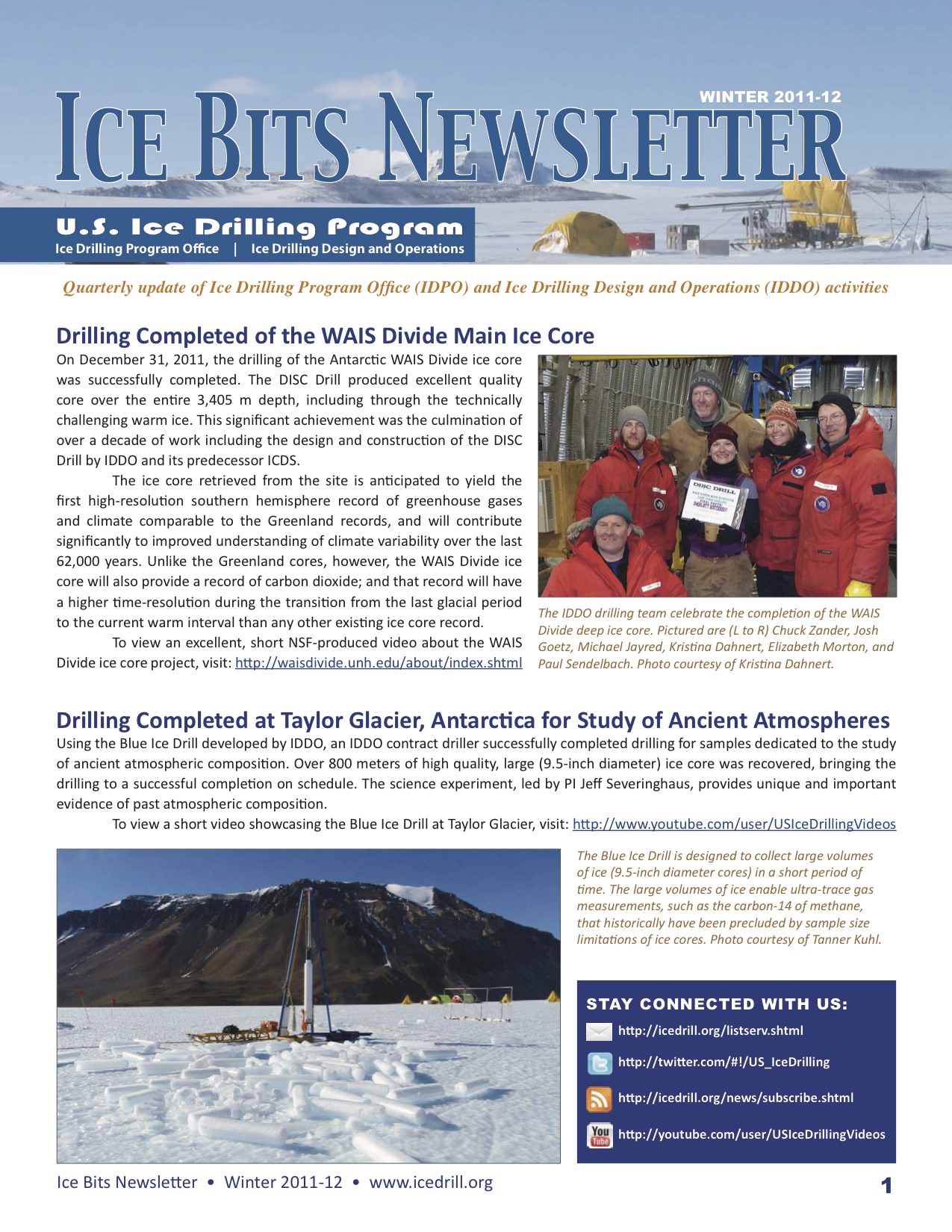

- Drilling Completed of the WAIS Divide Main Ice Core

- Drilling Completed at Taylor Glacier, Antarctica for Study of Ancient Atmospheres

- Replicate Coring System (2011 Winter)

- Rapid Access Ice Drill (2011 Winter)

- Intermediate-Depth Drill (2011 Winter)

- Educational Outreach (2011 Winter)

- Drilling Support to Science Projects (2011 Winter)

Topics:

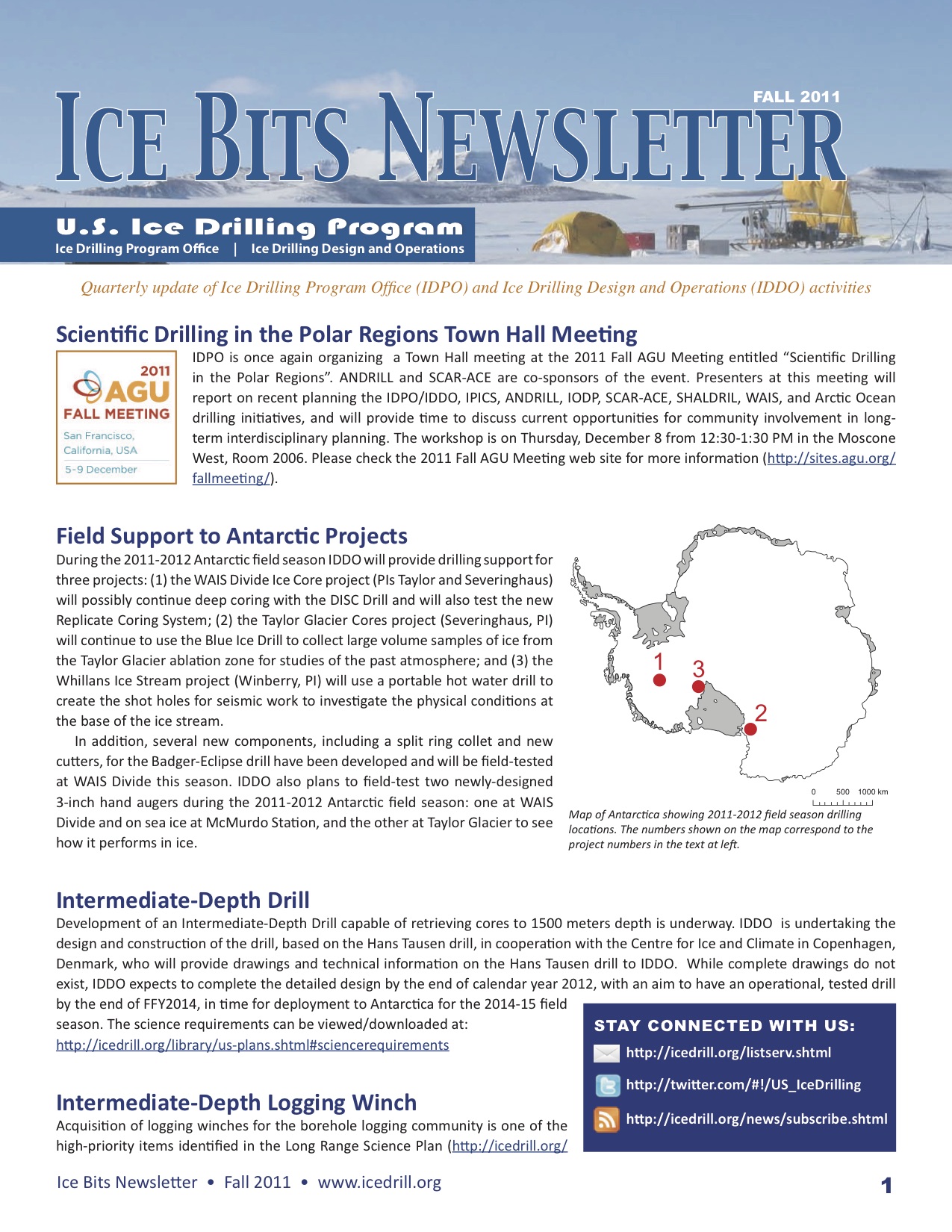

- Scientific Drilling in the Polar Regions 2011 Town Hall Meeting

- Field Support to Antarctic Projects (2011 Fall)

- Intermediate-Depth Drill (2011 Fall)

- Intermediate-Depth Logging Winch

- Rapid Access Ice Drill (RAID)

- Replicate Coring System (2011 Fall)

- Follow Us on Twitter

Topics:

- Overview of Activities (2011 Summer)

- Multidisciplinary Science on the Greenland Ice Sheet is Enabled by Agile Ice Core Drills

- Interdisciplinary Community Workshop Examines the Future for Ice Coring and Drilling

- Education and Outreach (2011 Summer)

- IDDO Career Opportunity - Mechanical Engineer(s) Needed!

- IPICS 2012 Open Science Conference

- Long Range Science Plan 2011-2021 and Long Range Drilling Technology Plan

- 2011 Technical Advisory Board (TAB) Meeting

Topics:

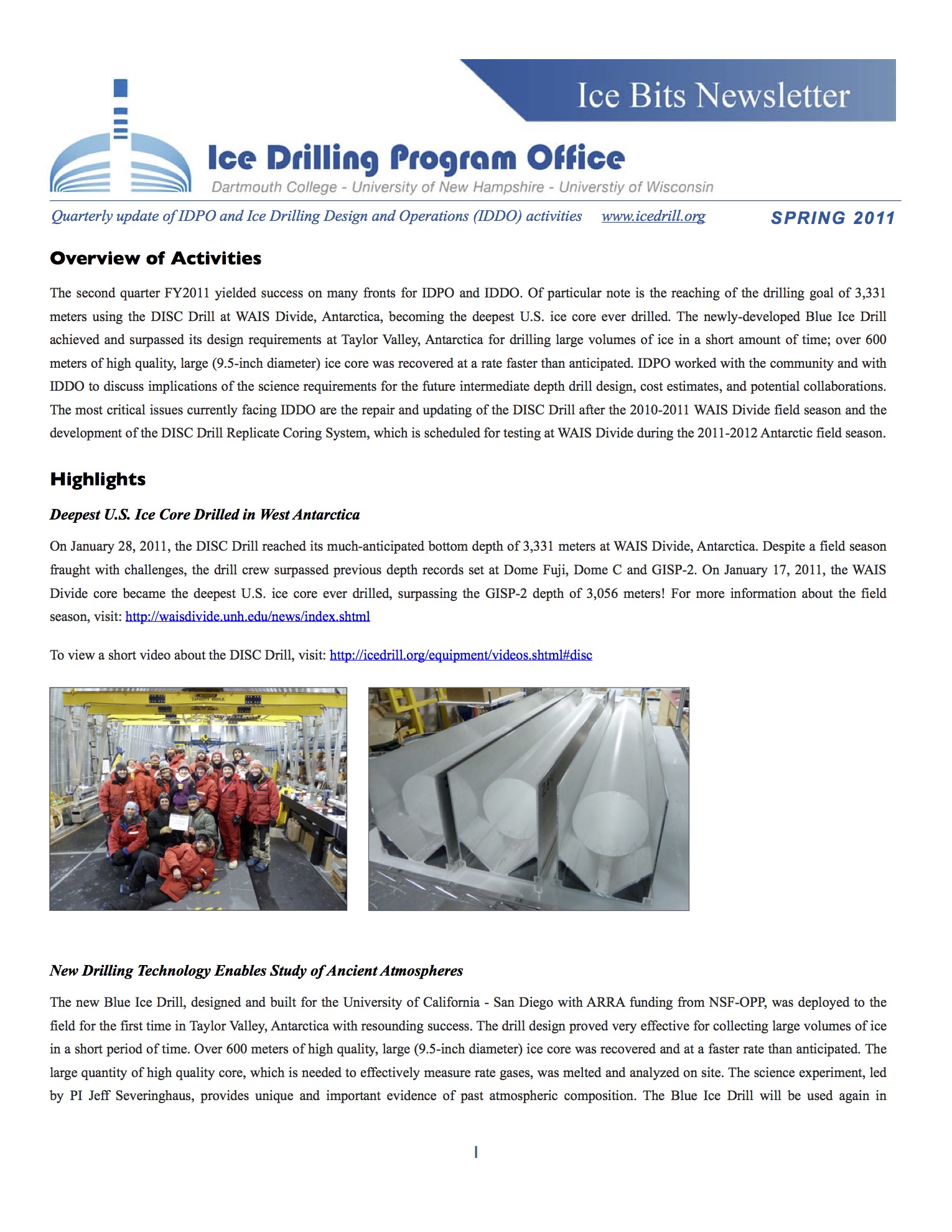

- Overview of Activities (2011 Spring)

- Deepest U.S. Ice Core Drilled in West Antarctica

- New Drilling Technology Enables Study of Ancient Atmospheres

- Unique Ice Drilling Technology Developed for Increased Sampling of Key Events

- 2011 Long Range Science Plan - Request for Community Input/Comment

- 2011 Science Planning Workshop Review

- Drilling Support to Arctic Field Projects (2011 Spring)

Topics:

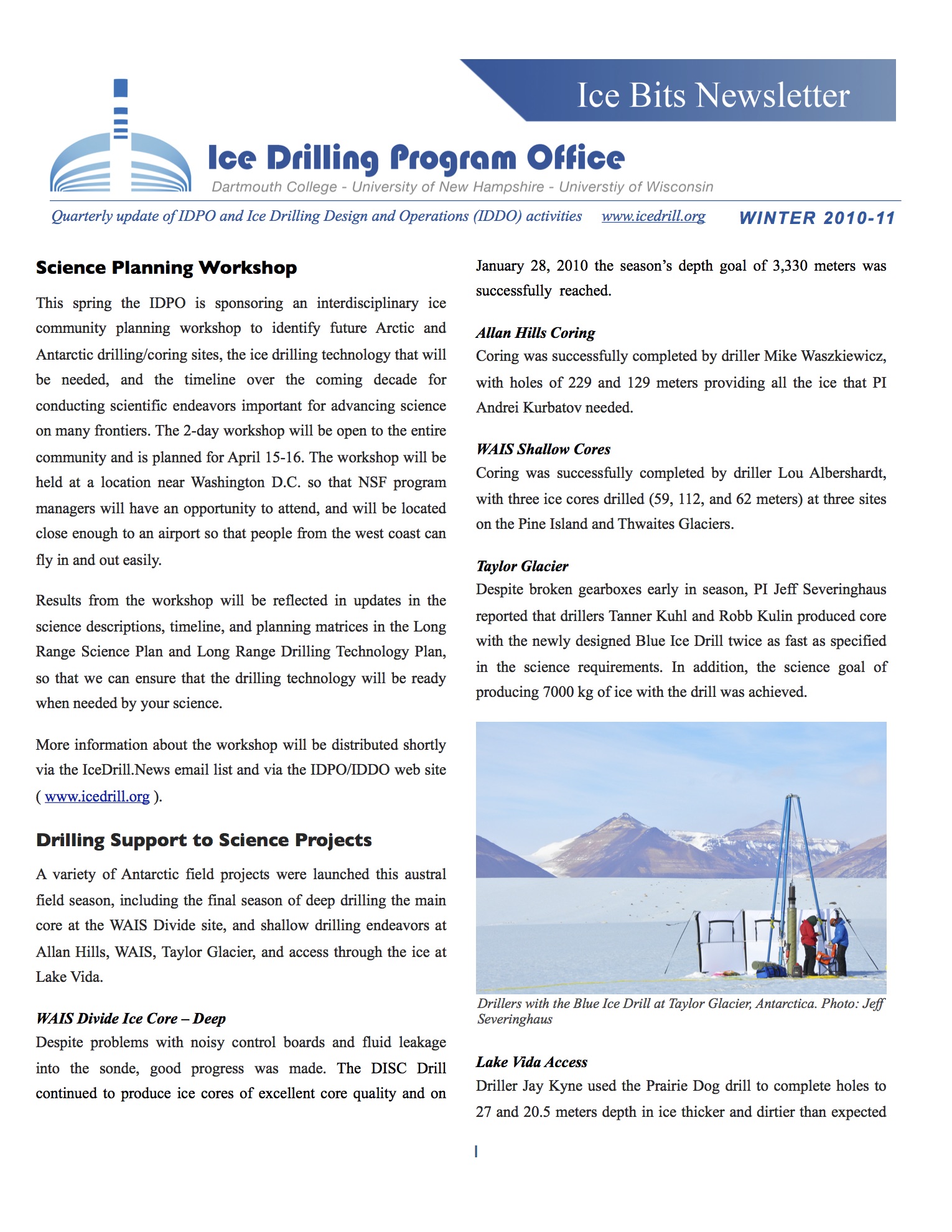

- 2011 Science Planning Workshop

- Drilling Support to Science Projects (2010 Winter)

- Intermediate-Depth Drill (2010 Winter)

- DISC Drill (2010 Winter)

- Replicate Coring System (2010 Winter)

- Educational Outreach (2010 Winter)

Topics:

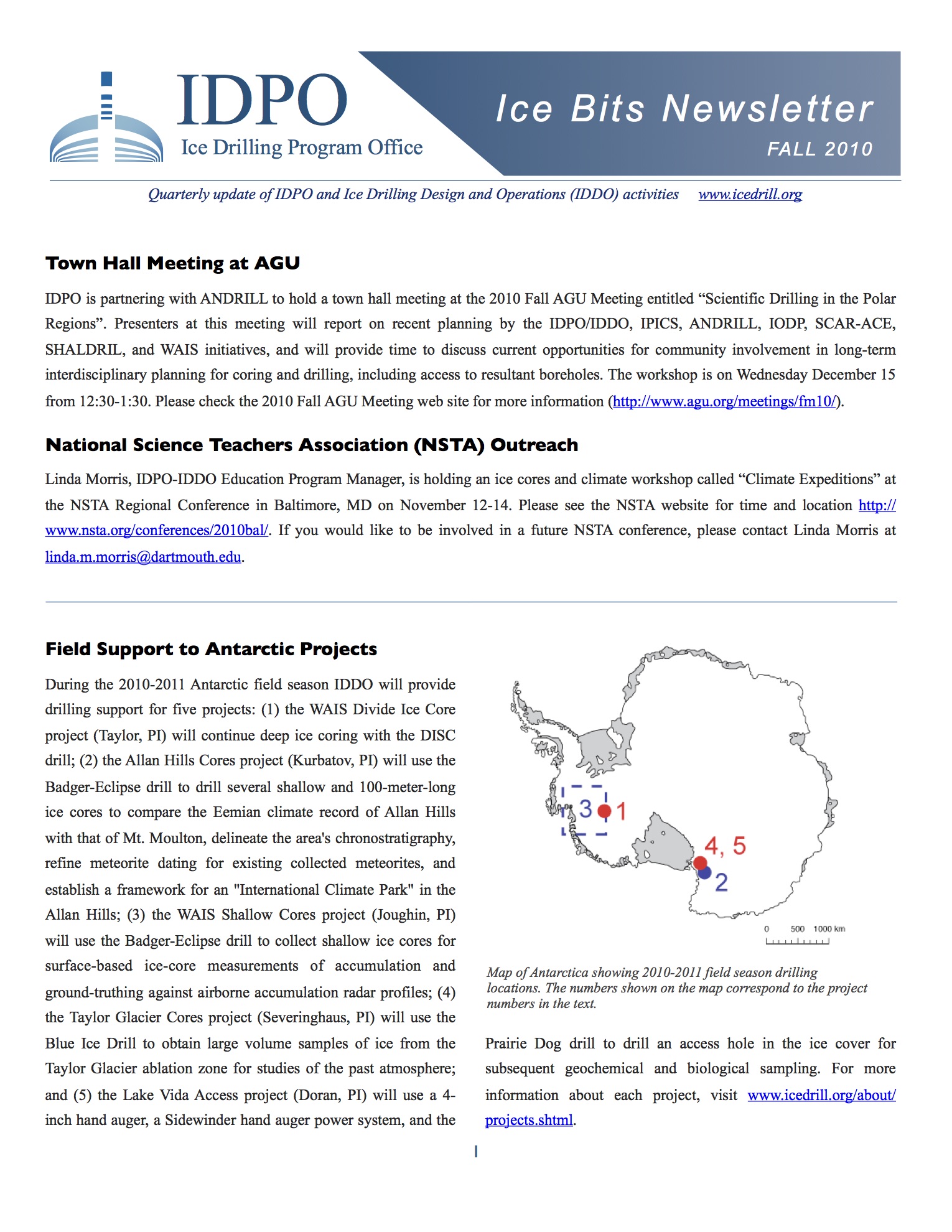

- Town Hall Meeting at AGU

- National Science Teachers Association (NSTA) Outreach

- Field Support to Antarctic Projects (2010 Fall)

- Replicate Coring System (2010 Fall)

- Intermediate-Depth Drill (2010 Fall)

Topics:

- Long Range Integrated Planning

- Planning Improvements to Agile Drilling

- Planning for New Capability

- Drilling Shallow Cores

- WAIS Divide Deep Ice Core

Topics:

- Draft Long Range Science Plan

- Update of Field Drilling Support (January - March, 2010)

- Development Highlights (January - March, 2010)